You design a beautiful, high-tech humidifier. It looks perfect in CAD. But two weeks after purchase, the customer smells mildew. Your premium product1 is now a biology experiment.

To engineer a truly mold-free tank2, you must eliminate surface roughness and internal corners where biofilm adheres. The solution is replacing complex plastic assemblies with seamless, deep-drawn stainless steel. This utilizes the material's passive chromium oxide layer to prevent bacterial growth without relying on temporary chemical coatings.

Many designers ignore the tank. They focus on the circuit board or the fan. This is a mistake. If you ignore the vessel, you destroy the user experience3. Let me explain why the tank is an engineering challenge, not just a plastic bucket.

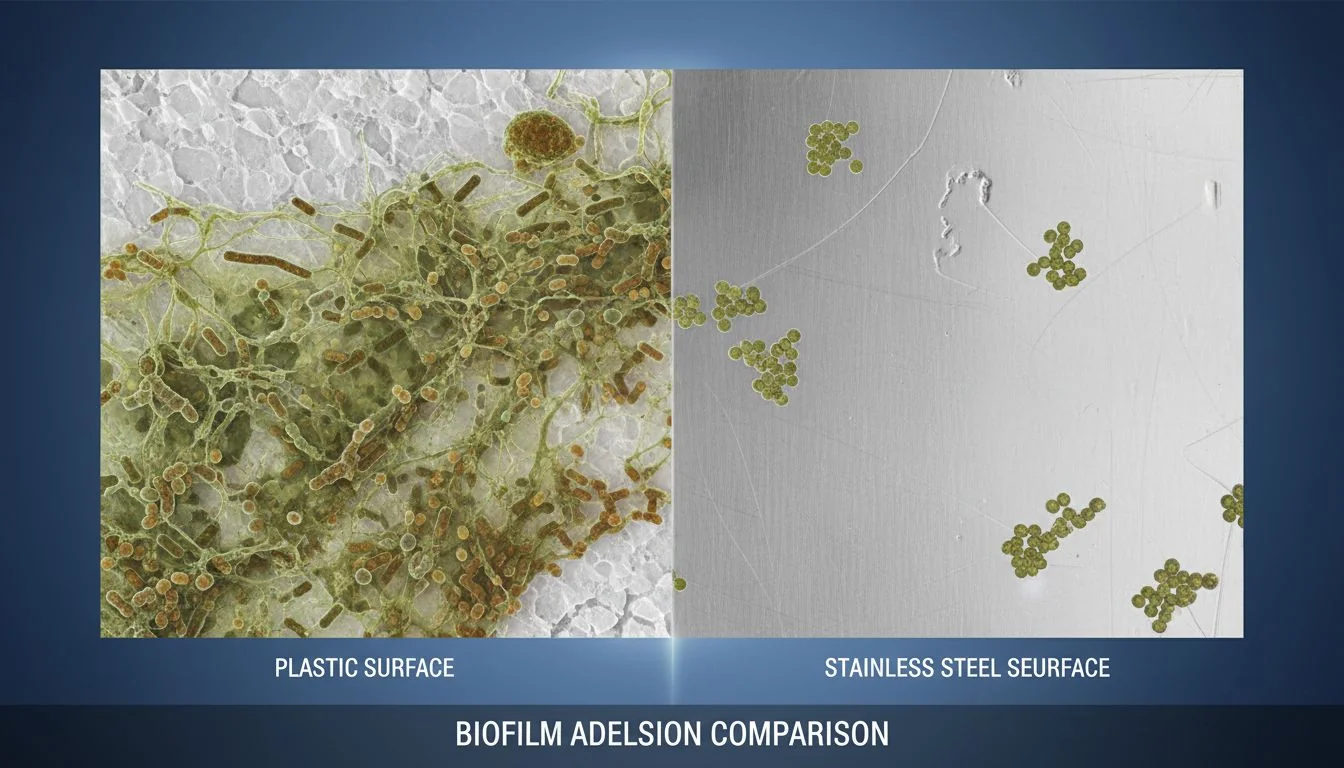

Biofilm begins to form on plastic surfaces within 24 hours in stagnant water.True

Bacteria attach to surface irregularities and secrete a protective matrix rapidly.

Injection molded plastic is smoother than polished stainless steel at a microscopic level.False

Plastic often has microscopic pores and surface energy that encourages adhesion, whereas electropolished steel is much smoother.

We spend months perfecting the outer shell and the user interface. Yet, we often treat the water tank as a simple commodity part. This oversight kills brand reputation.

The water tank is the "hidden failure point" because it is the only component that interacts with standing water and biology. While electronics are sealed, the tank is exposed. If you treat the tank as an afterthought, you invite mold, odor, and customer returns.

I have seen many "premium" humidifiers and purifiers in my time. They have sleek screens and app connectivity. But when you open them, the tank is cheap ABS plastic. This is a disconnect. You cannot have a $300 device with a $2 tank. The tank is not just storage; it is the foundation of hygiene.

The Disconnect in Design

When we design molds for these tanks, we often focus on cost. We add ribs for strength. We add sharp corners to fit the PCB. These are engineering decisions for assembly, not for hygiene. Every rib and every corner is a failure point.

The Cost of "Good Enough"

You might think plastic is fine. But plastic degrades. It scratches during cleaning. These scratches become homes for bacteria. A premium device must last for years, not months. If the tank fails, the whole machine fails.

| 기능 | Standard Plastic Tank | Premium Engineering Approach |

|---|---|---|

| 초점 | Cost reduction & Assembly | Hygiene & Longevity |

| Geometry | Complex ribs & corners | Smooth, seamless curves |

| Aging | Scratches & degrades | Remains passive & smooth |

| User Perception | "Cheap accessory" | "Core component" |

Generate Claims

Plastic tanks are cheaper to manufacture than deep-drawn steel.True

Injection molding cycles are fast and material costs are generally lower than stainless steel processes.

Consumers rarely notice the material of the water tank.False

Premium consumers inspect the water path closely; slime and odor are top complaints in user reviews.

Why do plastic tanks always smell due to biofilm adhesion?

You clean the tank, but the smell comes back in two days. This is not the user's fault. It is a failure of surface topography and material science.

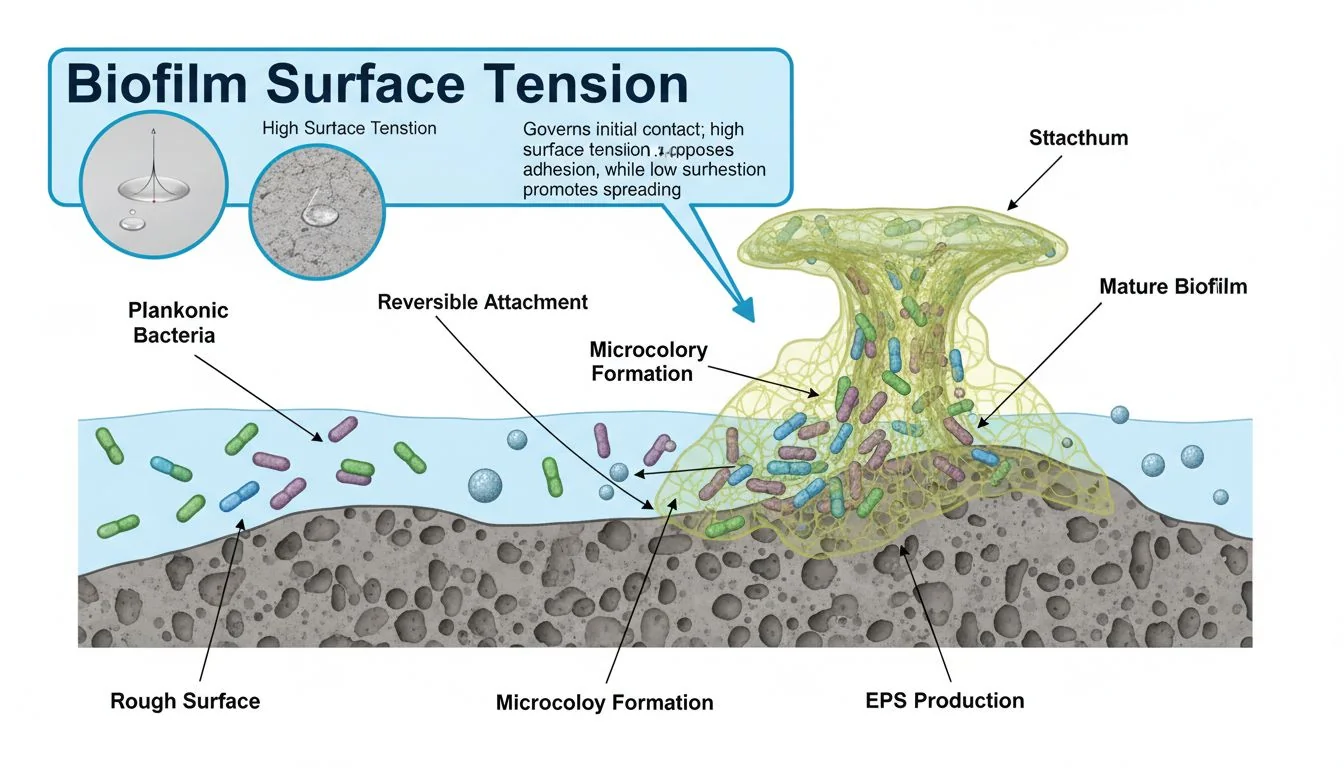

Plastic tanks smell because of "biofilm adhesion4." Biofilm is not just dirt; it is a colony of bacteria that creates a glue-like matrix. Plastic surfaces, even when smooth to the eye, have high surface energy and microscopic roughness that allow this matrix to anchor deeply and resist cleaning.

We need to stop calling it "slime." As engineers, we must call it a surface tension challenge. Biofilm is an engineering problem. It seeks an anchor point. Once it anchors, it builds a city.

Surface Roughness and Topography

In the mold industry, we talk about VDI texture standards. But for water tanks, even a polished plastic surface is porous on a molecular level. It absorbs odors. It allows the biofilm to grab on. When a user scrubs plastic, they create micro-abrasions. These abrasions increase surface roughness5. It becomes a cycle. The more they clean, the faster the mold returns.

The Geometry of Bacteria

Bacteria hide in the shadows. In an injection-molded tank, we have draft angles and ejector pin marks. We have 90-degree corners. These are dead zones. Water does not circulate there. Biofilm thrives in these stagnant, sharp corners. You cannot wipe a sharp corner perfectly clean.

| 요인 | Plastic Surface | Engineered Surface (Steel) |

|---|---|---|

| Micro-structure | Porous, absorbs organic matter | Dense, crystalline structure |

| Wear Resistance | Low (scrubbing creates grooves) | High (resists abrasion) |

| Adhesion | High surface energy (sticky) | Low surface energy (slick) |

Scrubbing a plastic tank improves its hygiene long-term.False

Scrubbing creates micro-scratches that increase surface area for bacteria to colonize.

Biofilm protects bacteria from standard cleaning agents.True

The extracellular polymeric substance (EPS) matrix acts as a shield against mild detergents.

How does the passive surface of stainless steel prevent bacterial growth?

You might think you need antibacterial chemicals. You don't. Nature provides a better solution through metallurgy. It is called the passive layer6.

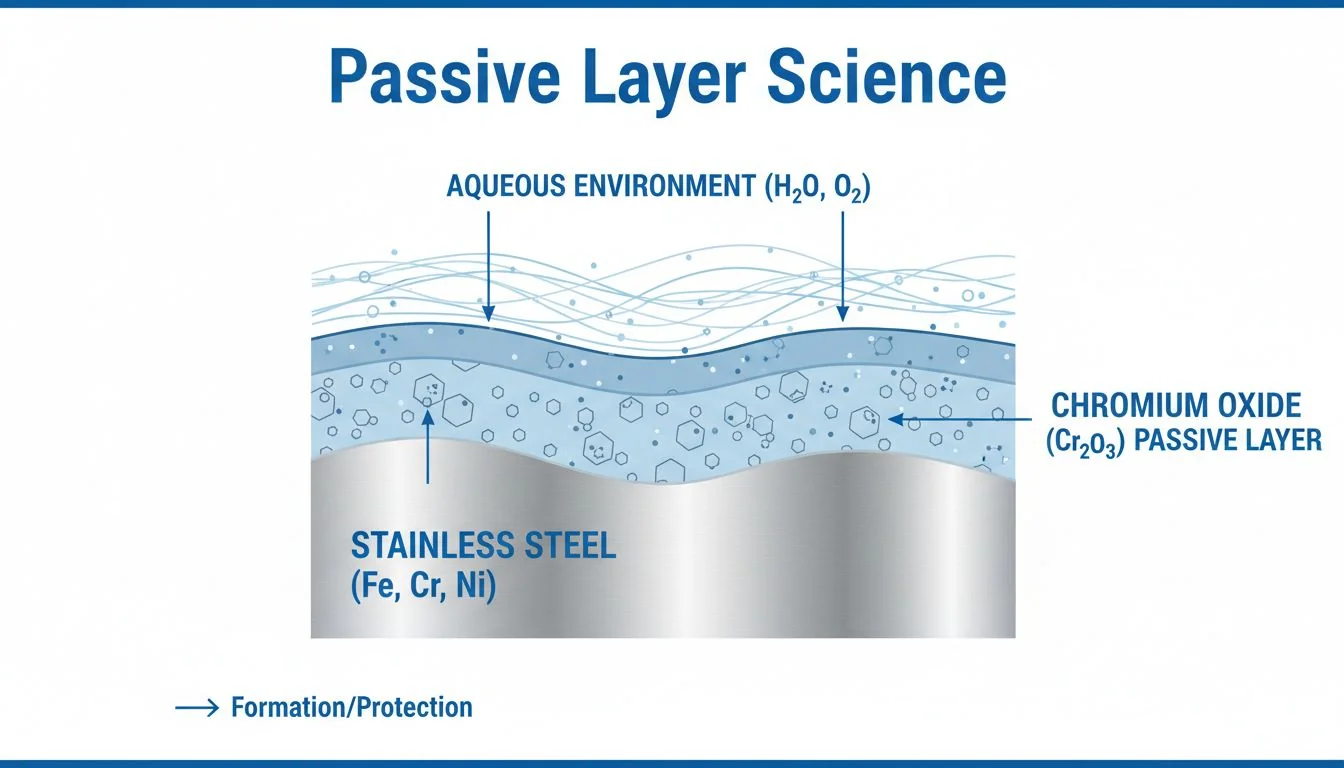

stainless steel7 does not need chemical coatings to be hygienic. It relies on a "Passive Layer" of chromium oxide. This atomic layer forms naturally when chromium reacts with oxygen. It is non-porous, self-healing, and prevents organic matter from bonding to the metal, making it inherently anti-microbial.

I often see brands adding "silver ion" coatings to plastic. This is a marketing gimmick. It wears off. Real engineering relies on material properties, not additives. The magic of stainless steel is not the steel itself; it is the reaction with air.

The Chromium Oxide Shield

When we use 304 or 316 stainless steel, we are utilizing a ceramic-like surface. This chromium oxide layer is incredibly thin, but it is chemically inactive. "Passive" means it does not want to react with the biology in the water. The bacteria try to land, but the surface offers no chemical bond. They slide off.

Self-Healing Engineering

If you scratch a plastic tank, the scratch stays forever. If you scratch stainless steel, the chromium reacts with oxygen in the air and "heals" the passive layer instantly. This is why medical tools are steel. It is the only way to ensure a consistently hygienic surface over ten years of use.

| Property | Antibacterial Coating (Plastic) | Passive Layer (Steel) |

|---|---|---|

| 내구성 | Temporary (washes off) | Permanent (self-healing) |

| 메커니즘 | Chemical toxicity | Physical/Chemical barrier |

| 안전 | Leaches chemicals into water | Inert and food-safe |

Generate Claims

Stainless steel kills bacteria actively like bleach.False

It is passive; it prevents adhesion and growth rather than actively poisoning the bacteria.

The passive layer requires special maintenance to regenerate.False

It regenerates automatically in the presence of oxygen.

Why is seamless deep-draw technology a manufacturing moat?

Anyone can mold a plastic box. Very few can deep-draw a seamless steel bowl. This difficulty is your advantage. It proves your quality.

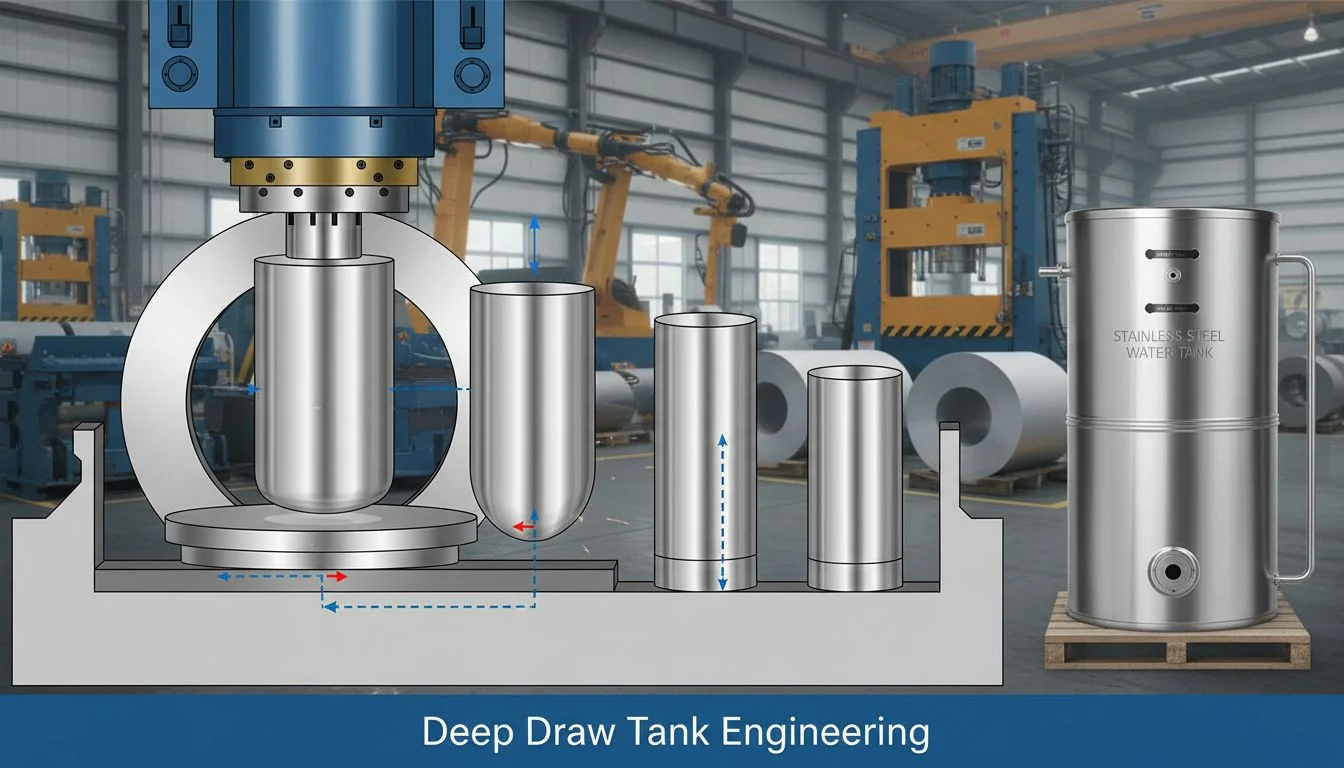

"Deep-Draw" technology involves stretching a flat sheet of steel into a deep shape using high-tonnage presses. This creates a tank with zero seams, zero welds, and zero sharp corners. It is a "manufacturing moat" because the tooling is expensive and the process requires high precision, making it hard for cheap competitors to copy.

As a mold guy, I respect deep drawing. It is brutal. You are forcing metal to flow like liquid. If your calculations are wrong, the metal tears. If the lubrication is wrong, it wrinkles. But the result is an engineering marvel.

Seamless Equals Mold-Free

Why do we go through this trouble? Because seams are dirty. In plastic tanks, you often glue two parts together or snap them shut. That seam is a hotel for mold. A deep-drawn tank is one continuous piece of matter. There is nowhere for the dirt to hide.

The Geometry of Cleanliness

Deep drawing forces you to use large radii. You cannot draw a sharp corner in steel; the metal will rip. This limitation is actually a feature. It forces the design to have smooth, sweeping curves. These curves are easy to wipe. The water flows freely. The geometry itself fights the mold.

| 측면 | 사출 성형 | Deep-Draw Stamping |

|---|---|---|

| Complexity | Can make complex ribs/bosses | Limited to open shapes |

| Hygiene | Corners trap dirt | Large radii are easy to clean |

| Barrier to Entry | Low (cheap molds available) | High (expensive, heavy tooling) |

Deep drawing allows for complex internal ribs and mounting points.False

Deep drawing creates a shell; you cannot easily add internal geometry without secondary welding.

A seamless tank eliminates the risk of leaking gaskets.True

Without bottom seams or joints, the primary leakage paths are removed.

Your customer does not care about the voltage. They care about the taste and the smell. Odor is the death of trust.

For a premium brand, "Odor-Free" is the ultimate metric of quality. It signifies "Flavor/Scent Integrity." If a $300 purifier makes the water taste like plastic or smell like swamp, the brand equity is destroyed. A sterile, stainless tank protects the purity of the output, justifying the premium price point.

I have built my career in manufacturing. I know that specs matter. But to the user, the "spec" is the experience. Smell is our most primal sense. It is connected directly to the brain's danger center.

The "Plastic Taste" Problem

We have all tasted water from a cheap bottle. It tastes synthetic. That is the plastic leaching volatile organic compounds (VOCs). In a humidifier, this becomes an airborne smell. A premium device cannot emit a synthetic smell. It must be neutral.

Building Trust through Steel

When a user opens the box and sees a polished steel tank, they feel the value. It feels like a kitchen appliance, not a toy. It feels like a medical device. This builds trust. They know that the water they put in is the water they get out. There is no chemical alteration. That is what they are paying for.

| Metric | Plastic Experience | Stainless Experience |

|---|---|---|

| Sensory | Chemical smell / Moldy | Neutral / Fresh |

| Psychology | "Disposable" | "Permanent" |

| Brand Value | Commodity | Luxury / Professional |

Users can detect plasticizers in water at very low concentrations.True

Human sensitivity to certain VOCs and off-flavors is extremely high.

Stainless steel adds a metallic taste to water.False

High-quality food-grade stainless steel (304/316) is inert and does not impart flavor.

결론

Don't let a cheap tank ruin a premium product. By choosing deep-drawn stainless steel, you solve the biofilm challenge through engineering, not chemicals. Build a vessel worthy of your technology.

References

-

Explore the characteristics that distinguish premium products and their impact on consumer perception. ↩

-

Explore effective strategies and technologies to ensure your tank remains mold-free, enhancing product quality. ↩

-

Learn how thoughtful product design can enhance user experience and satisfaction. ↩

-

Understand the science behind biofilm adhesion and its implications for hygiene in water tanks. ↩

-

Investigate the relationship between surface roughness and bacterial adhesion in various materials. ↩

-

Learn about the passive layer's role in preventing bacterial growth and maintaining hygiene. ↩

-

Find out why stainless steel is the material of choice for hygienic water storage solutions. ↩