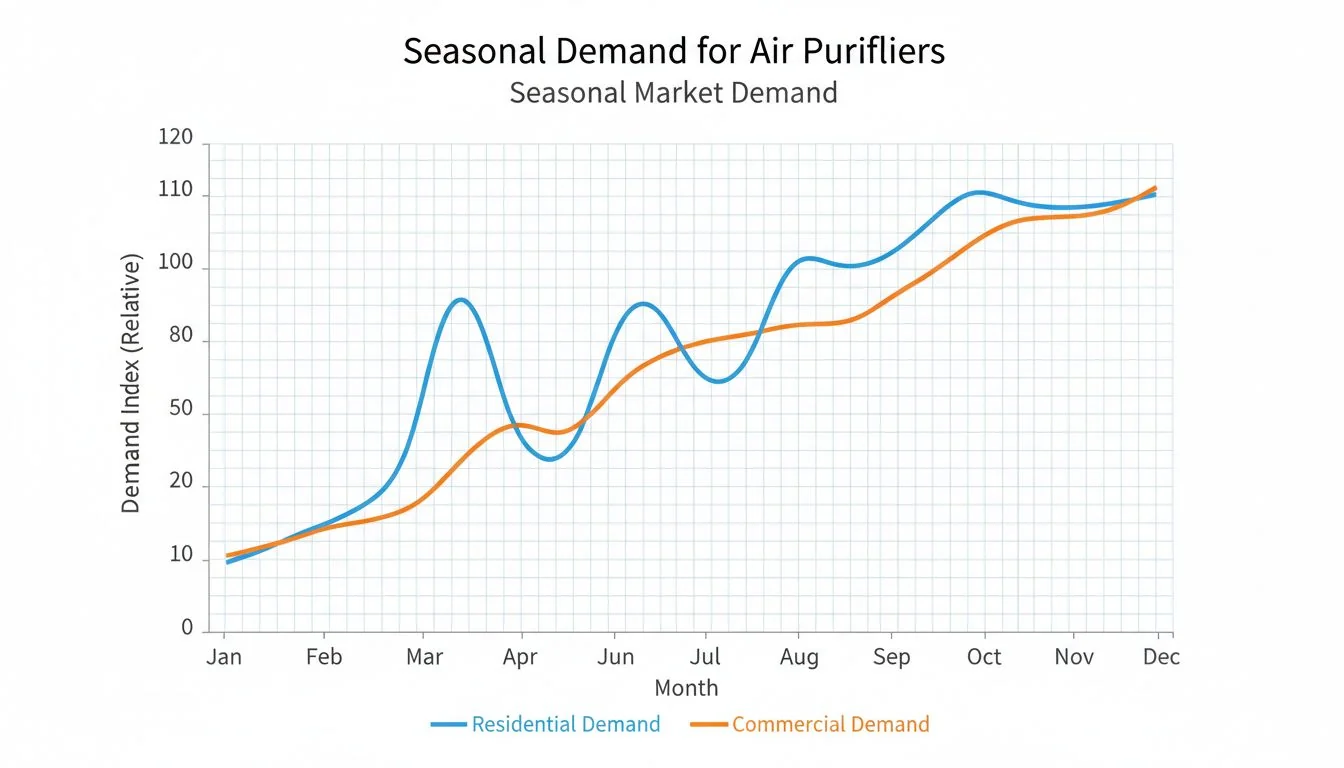

You watch the wildfire season start, and your competitors are already selling their "Smoke Defense" units while you are still stuck in the prototyping phase. If you miss the seasonal window, you don't just lose sales; you lose your relevance in the market.

To launch a new air purifier in record time, you must shift from traditional OEM manufacturing to a pre-certified platform strategy1. By using a partner that provides the "Guts" (motor, fan, filter) and focusing your design efforts only on the "Skin" (casing and UI), you can reduce development time from 12 months to 90 days. This allows you to use "Multiple Listing" for compliance rather than full testing.

Most designers think they need to build every part of a product from scratch to make it unique, but this mindset is exactly what kills your profit margins. Let me show you how to change your approach.

Traditional R&D cycles for air purifiers take 12 to 18 months.True

Designing internal airflow mechanics and passing safety certifications requires extensive iteration and lab time.

You must design the motor and fan yourself to have a unique product.False

You can differentiate a product entirely through industrial design (the Skin) while using a standardized, high-performance internal core.

Why Is Speed Your Most Critical Feature?

In the Direct-to-Consumer (D2C) world, your ability to move fast is your only real defense against big corporations. If you cannot hit the market when the demand is highest, your perfect design does not matter.

Speed is the "moat" that protects your business. When you can launch a "Wildfire Season Special Edition" or a "Spring Allergy Bundle" exactly when customers are searching for it, you win the sale. You need a partner like Hisoair that is agile enough to help you hit these tight seasonal windows.

I have seen too many brilliant designers get stuck in the pursuit of perfection. We often talk about "Time-to-Market2" as a buzzword, but we rarely calculate the real cost. I want you to think about the "Opportunity Cost" of a slow launch. Every month you spend in R&D is a month of zero revenue. If you spend 18 months developing a product that could have been launched in 3 months, you have lost 15 months of sales.

For a startup or a mid-sized brand, that loss is often fatal. By cutting your launch time by 12 months, you are effectively giving your company one full year of extra revenue. This justifies paying a premium for a platform that speeds you up.

When I ran my mold factory, I saw clients miss Christmas deadlines because they wanted to tweak a fan blade by 2 millimeters. The customer does not care about the fan blade curve; they care if the product is available when the smoke is in the air. Hisoair understands this. They position themselves not just as a factory, but as a "Launchpad." This is the mindset you need. You are not just building a tool; you are launching a business trajectory.

Missing a seasonal window like wildfire season can result in a 40% drop in annual potential revenue.True

Air purifier sales are highly seasonal, driven by allergies and air quality events.

Faster time-to-market always results in lower product quality.False

Using pre-validated platforms actually increases quality because the core components are already tested and proven.

Why Do Traditional OEM Projects Stall in the "Slow Lane"?

The traditional Original Equipment Manufacturer (OEM) model is broken for brands that need speed. You start with a sketch, then you move to mechanical engineering, and then you hit the wall of mold production and testing.

Traditional projects stall because you are trying to reinvent the wheel—literally. Designing the internal airflow system, balancing the fan, and creating molds for the motor housing takes months of trial and error. This is the "Slow Lane3" where good ideas go to die.

Let's look at this from a mold design perspective, which is my background. When you decide to build the entire unit from scratch, you are taking on a massive engineering burden. You have to calculate shrinkage for complex internal parts that hold the motor. You have to design cooling lines for molds that produce the fan blades to ensure they don't warp and cause noise.

Here is a breakdown of why the "Slow Lane" takes so long:

| Development Stage | Typical Duration | The Bottleneck |

|---|---|---|

| Airflow Simulation | 4-8 Weeks | You must simulate CFD (Computational Fluid Dynamics) to ensure the CAD works. |

| Internal Tooling | 12-16 Weeks | Cutting steel for complex motor mounts and fan housings is slow. |

| T0 to T1 Trials | 4-8 Weeks | The first shots never work perfectly. You have noise issues or vibration. |

| 인증 | 12-24 Weeks | If the motor gets too hot during lab tests, you start over. |

I remember a project where we spent six months just trying to get the fan balancing right. The mold for the fan blade had a cooling issue, causing a 0.1mm warp. That warp caused a hum that ruined the user experience. We fixed it, but the client missed their launch date. When you choose the Slow Lane, you are choosing to solve physics problems instead of selling products.

Mold flow analysis can predict 100% of manufacturing defects.False

While analysis helps, physical trials (T0, T1) often reveal unforeseen issues with warping, sink marks, or assembly fit.

Fan blade tooling requires high-precision machining.True

Even minor imbalances in fan blades cause noise and vibration, requiring expensive and slow tooling adjustments.

What Is the "Fast Lane" Pre-Certified Platform Strategy?

The "Fast Lane4" is about understanding where your value lies. You are a brand builder and a designer, not a motor manufacturer. The strategy here is to separate the product into two categories: the "Skin" and the "Guts."

The "Fast Lane" strategy uses a pre-certified platform for the internal mechanics. You leave the "Guts" (motor, fan, filter, sensors) to an expert partner like Hisoair, and you focus all your energy on the "Skin" (color, control panel, outer casing). This is the formula for speed.

Think of this like buying a car chassis and engine from a racing team, and then building your own custom body on top of it. The "Guts" of an air purifier take years to perfect. You need to optimize the Clean Air Delivery Rate (CADR), ensure the motor is silent, and source the right HEPA filters. Why would you redo that work?

When you use a platform strategy, you are essentially buying a "Launchpad." You take a proven core that already works. Your job, Jacky, changes from a mechanical engineer worrying about motor heat dissipation to a product designer focusing on aesthetics and user experience.

Here is why the "Skin vs. Guts" approach works for you:

- Reduced Tooling Risk: You only need to cut molds for the exterior shell. These are simpler molds. They are usually open-shut tools without complex sliders or lifters required for internal mechanics.

- Predictable Performance: You know exactly how much air the unit will move before you even start drawing the shell. The specs are guaranteed.

- Focus on Brand: You can spend your budget on a premium texture, a beautiful touch screen, or a unique color finish. These are the things the customer actually sees and touches.

I have helped clients switch to this model. Instead of asking me to design a mold for a fan hub, they ask me to texture the mold for the front grill. The result is a product that looks custom but is built on a standardized, reliable engine.

The 'Skin' of the product accounts for 90% of the customer's first impression.True

Customers judge value based on aesthetics, touch, and UI, not the internal motor placement.

Using a platform strategy means your product will look like everyone else's.False

You have full freedom over the external shape, color, and interface, allowing for complete visual differentiation.

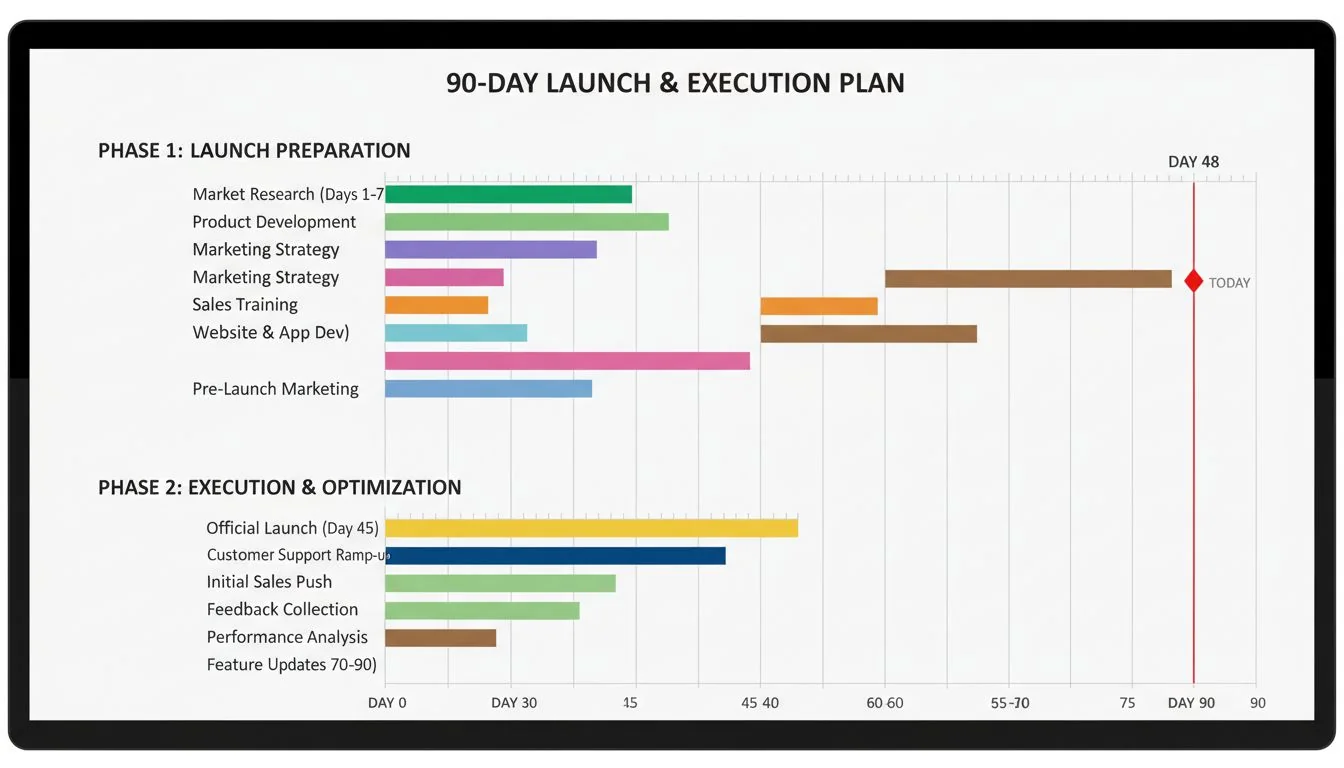

How Do You Execute a 90-Day Launch Step-by-Step?

Launching in 90 days sounds impossible if you are used to the 18-month cycle, but it is standard procedure when you use the Launchpad model. It requires strict discipline and a clear roadmap.

To execute a 90-day launch, you must parallel process your tasks. While your partner prepares the internal units, you finalize the exterior design and cut the molds for the housing. This synchronized dance eliminates the downtime found in linear project management.

Let's break this down into a schedule that you can actually use. This is not theory; this is a production schedule I have seen work.

Month 1: Selection and Design Freeze

- Week 1-2: You select the "Guts" platform based on the CADR you need (e.g., a room size of 300 sq ft). You receive the 3D STEP files of the internal core from Hisoair.

- Week 3-4: You design the "Skin" around this core. You verify the fit in CAD. You 3D print the shell to check the look and feel. By the end of the month, you freeze the design.

Month 2: Tooling and Packaging

- Week 5-8: We start cutting the molds for the exterior shell. Since we are not waiting for motor testing, we cut steel immediately. At the same time, your marketing team designs the box and the manual.

- Week 8: T1 samples of the shell are ready. We check the texture and color.

Month 3: Assembly and Logistics

- Week 9-10: We do a trial assembly. We put the pre-made "Guts" into your new "Skin." We check for gaps or rattles.

- Week 11-12: Mass production begins. The units are boxed and shipped.

The key here is that the "Guts" are already sitting on the shelf or are in continuous production. You are not waiting for a motor supplier to deliver a sample. You are plugging a verified engine into your new design. This is how you hit the "Wildfire Season" window while your competitors are still waiting for their T2 samples.

Parallel processing can reduce project timelines by 50%.True

By overlapping the supply chain preparation with the mold manufacturing, you remove sequential delays.

You should wait until the molds are finished to design the packaging.False

Packaging design should happen while molds are being cut to ensure everything is ready for the final assembly date.

How Does the "Compliance Accelerator" Help You Skip the Lab Wait?

The biggest hidden killer of product launches is the certification lab. You can have a perfect product, but if it sits in a queue at UL or ETL for four months, you miss your season.

The "Compliance Accelerator" is the difference between "Testing" and "Listing." Testing a new product takes months and costs a fortune. Listing your brand on an existing certificate (Multiple Listing5) takes weeks and costs a fraction of the price. This is the insider knowledge that saves your launch.

I want to explain this technically because it is vital for your role. When you design a product from scratch (the Slow Lane), you must submit it for a "New Investigation." The lab has to stress test the motor, check the temperature rise of the coils, and burn the plastic to check flammability. This takes 3 to 6 months.

However, when you use a platform like Hisoair, the "Guts" are already certified. The motor, the PCB, and the safety systems already have a file number with the safety agencies.

We use a process called Multiple Listing. Basically, the factory gives the safety agency permission to add your brand name and your specific model number to their existing file.

- The Lab's View: "This is the same internal machine we already tested; it just has a different plastic shell."

- The Result: They review the paperwork, check that your plastic material meets the flammability rating (usually V-0 or HB), and issue the certificate.

This process takes about 2 to 3 weeks. You skip the line. You skip the destructive testing. You skip the risk of failure. For a founder or a project manager, this certainty is worth its weight in gold. You are not just buying parts; you are buying a cleared path through the bureaucracy.

Full safety certification for a new electrical appliance takes 2 weeks.False

New investigations typically take 12-16 weeks due to lab backlogs and testing duration.

Multiple Listing allows you to market a product under your own brand using a partner's certification.True

This is a standard industry practice that legally allows you to use safety marks like UL or ETL based on the OEM's existing approval.

결론

To win in the consumer electronics market, you cannot let R&D slow you down. By treating speed as your competitive moat and using a "Launchpad" partner like Hisoair, you can bypass the years of development usually required for "Guts" and focus on the "Skin" that builds your brand. Don't test; list. Don't wait; launch.

References

-

Understanding this strategy can help you accelerate product launches and maintain market relevance. ↩

-

Exploring Time-to-Market can reveal how speed impacts sales and competitiveness in the market. ↩

-

Identifying the Slow Lane's pitfalls can help you avoid common mistakes that delay product launches. ↩

-

The Fast Lane strategy can provide insights into efficient product development and market entry. ↩

-

Learning about Multiple Listing can save you time and costs in the certification process for new products. ↩