Your plastic products are being rejected by health-conscious consumers. They see "BPA-free1" as an empty promise and worry about microplastics. You need to understand this shift to stay relevant.

This consumer now expects water purifiers made from inert materials like stainless steel2, glass, or ceramic. They demand products that are durable, non-leaching, and align with a holistic view of health, viewing plastic-free as the only true standard for purity.

As a mold designer, you might think this is a niche market. But I've seen these trends grow from small concerns into major market drivers. I remember when "BPA-free" was the big challenge we had to solve in our designs. Now, the conversation has moved on completely. Your clients will soon be asking for designs that eliminate plastic entirely from any surface that touches food or water. Understanding this "why" is critical before you can tackle the "how." Let's look at what's driving this change.

BPA is a synthetic estrogen that can disrupt the endocrine system.True

Bisphenol A (BPA) is a well-documented endocrine disruptor that mimics estrogen in the body, linked to various health issues.

All 'BPA-free' plastics are completely safe and do not leach chemicals.False

Many 'BPA-free' plastics use replacements like BPS or BPF, which studies suggest may have similar or even worse endocrine-disrupting effects.

The "BPA-Free" Myth: Why Is "Safer" Plastic No Longer Enough?

You've spent years mastering molds for "BPA-free" plastics. Now, consumers are saying it's not good enough. This shift can feel frustrating and threatens to make your expertise obsolete.

"BPA-free" is now seen as a marketing tactic. Savvy consumers know that replacement plasticizers like BPS and BPF are often used. They believe these can be just as harmful, so they now demand products with zero plasticizers, meaning no plastic at all.

From Better Plastic to No Plastic

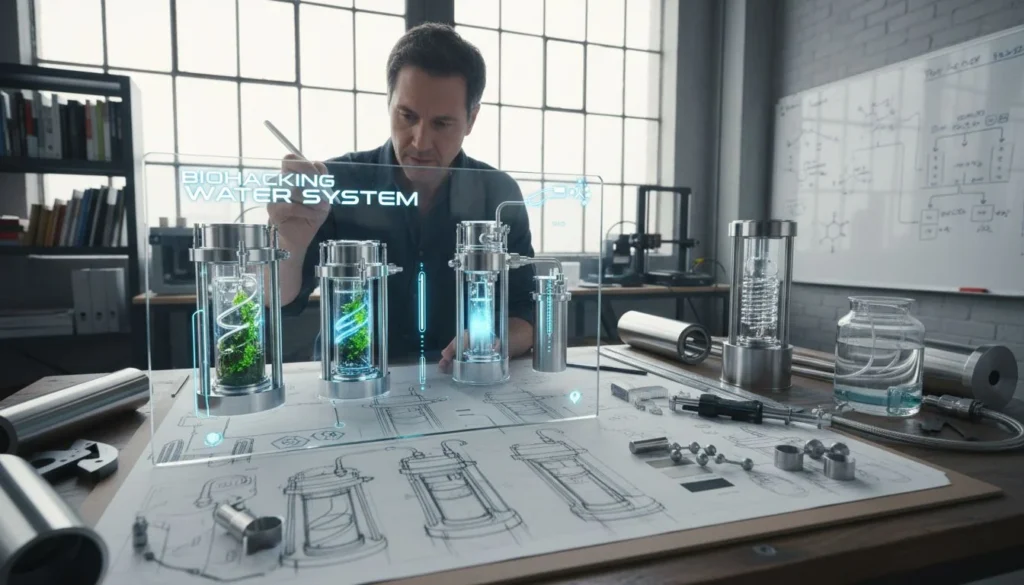

In my early days, the goal was always to find a better plastic. We worked with polycarbonate, then we moved to copolyesters like Tritan when the market demanded "BPA-free." Each shift brought new challenges for mold design, like different shrinkage rates and processing temperatures. But the fundamental material was the same. Today, the expectation has evolved beyond simply replacing one chemical with another. The new benchmark is material inertness. Consumers want materials that don't interact with their water at all. For a designer like you, Jacky, this means you need to start thinking outside the plastic injection mold. The conversation is no longer about which grade of plastic to use, but whether to use plastic at all.

| Material Concern | Traditional Solution (Plastic) | Modern Expectation (Non-Plastic) |

|---|---|---|

| Chemical Leaching | "BPA-Free" plastics (Tritan, etc.) | Glass, Stainless Steel, ceramic3 |

| Material Origin | Petroleum-based polymers | Natural or inert materials |

| Design Focus | Mitigating plastic's weaknesses | Leveraging new material strengths |

Tritan copolyester is a common BPA-free plastic.True

Eastman Tritan™ copolyester is a popular plastic used in food and drink containers, known for its clarity, durability, and being free of BPA, BPS, and other bisphenols.

If a plastic is 'BPA-free,' it contains no other bisphenols.False

Some BPA-free products replace BPA with other bisphenols like BPS, which research indicates may have similar health concerns.

Your design purifies water perfectly. But what if the purifier itself is contaminating the water? This is the core problem consumers now see with plastic water filters and pitchers.

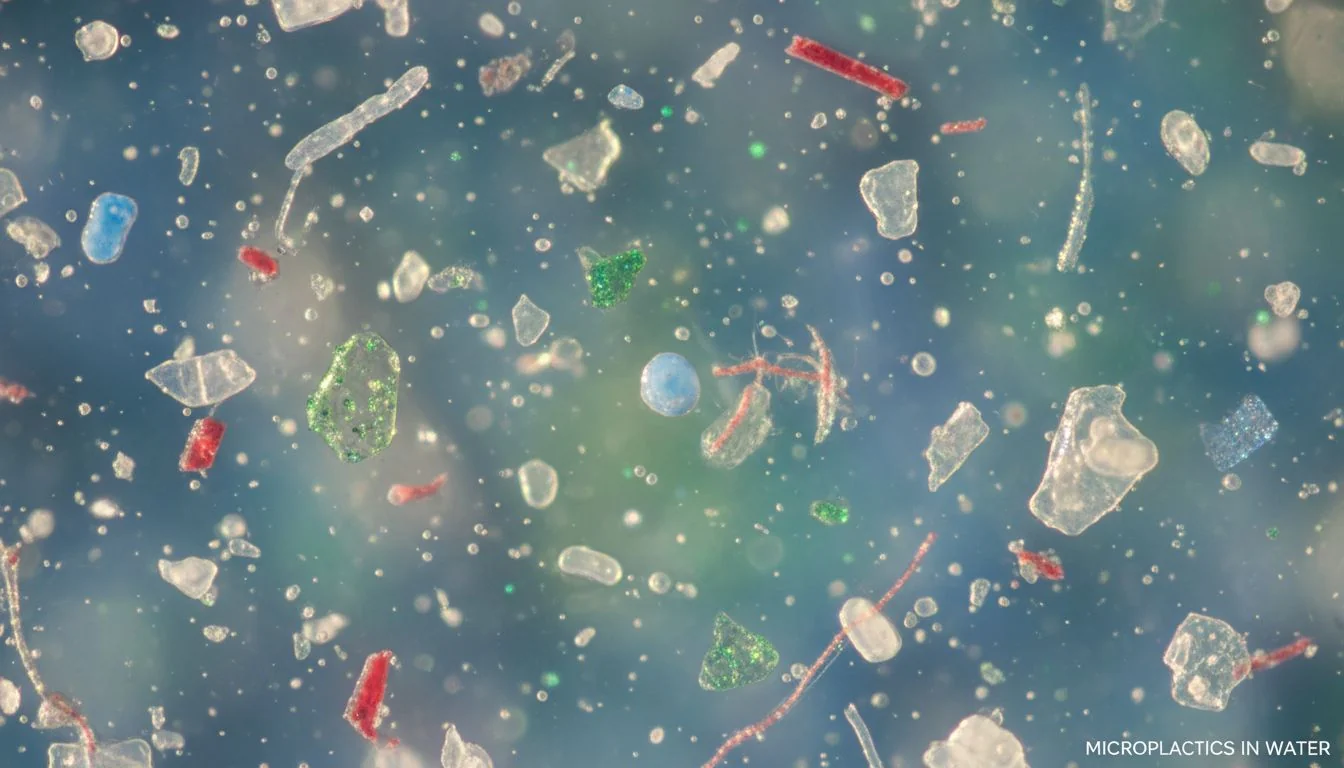

Consumers are now widely aware that plastic products shed microplastics4. The idea of a plastic device "purifying" water only to re-contaminate it with plastic particles is a major design flaw in their eyes. They see it as fundamentally counter-intuitive and unacceptable.

Designing Against Self-Contamination

I once consulted on a project involving a water filter pitcher where users reported a "plastic taste" over time. We discovered that the daily stress of use, like clicking the lid on and off and the friction of the filter cartridge, was causing material degradation. These actions were creating and releasing micro-particles into the very water it was supposed to be cleaning. This is a mechanical design problem. As a product designer, you must consider how parts interact, the friction they create, and how the material ages. With plastics, degradation is a given. With stainless steel or glass, it's a non-issue. This consumer insight forces us to design for material stability over the product's entire lifecycle, not just for its initial function.

| Design Factor | Plastic Purifier Risk | Non-Plastic Alternative |

|---|---|---|

| Friction Points | Lid, handle, filter housing can shed particles. | Metal-on-metal or glass-on-silicone have low shedding. |

| UV/Heat Exposure | Can accelerate plastic breakdown and leaching. | Glass and steel are stable under heat and UV. |

| Cleaning/Abrasion | Scrubbing can release microplastics. | Surfaces are non-porous and highly durable. |

A 2019 study found that the average person could be ingesting up to 5 grams of plastic every week.True

A study by the University of Newcastle, commissioned by WWF, estimated that people consume about 2,000 tiny pieces of plastic each week, equivalent to the weight of a credit card.

Water filters remove all microplastics from your water, even if the filter is made of plastic.False

While some filters can remove microplastics from the source water, the plastic housing and components of the filter itself can add microplastics back into the filtered water.

Holistic Purity: Do Your Product's Materials Align With Its Values?

A product promises "natural, pure water." But it's made from plastic, a synthetic petroleum byproduct. This creates a disconnect for consumers who seek alignment in their lifestyle choices.

Modern wellness consumers demand "holistic purity5." This means the product's materials must be as clean and natural as its function. A plastic purifier feels inherently misaligned with a "clean living" ethos, regardless of its filtering performance.

The Story the Material Tells

Think about the products you design, Jacky. Every material choice tells a story. Plastic tells a story of convenience, mass production, and chemistry. For many applications, this is a great story. But for a product centered on health and purity, it's the wrong one. I've seen clients gain huge market advantages by switching to materials that better match their brand story. A water purifier made of polished 304 stainless steel6 tells a story of professionalism, hygiene, and permanence, like surgical equipment. A glass carafe tells a story of clarity, purity, and simplicity. These materials don't just perform a function; they reinforce the core promise of the product. Your role as a designer is expanding. You're not just a technical expert; you're a storyteller who uses materials as your language.

| 재료 | Perceived Story & Values | Design Implication |

|---|---|---|

| 플라스틱 | Convenience, disposability, synthetic. | Feels contradictory for a "purity" product. |

| Glass | Purity, transparency, simplicity, inertness. | Reinforces the promise of clean water. |

| Stainless Steel | durability7, hygiene, professionalism, "buy it for life." | Communicates a long-term investment in health. |

| Ceramic | Natural, earthy, artisanal, traditional. | Appeals to a natural, back-to-basics ethos. |

Plastic is a byproduct of petroleum refining.True

Most common plastics are polymers derived from hydrocarbons, which are obtained from the fossil fuels petroleum (crude oil) and natural gas.

The material of a container has no psychological effect on a consumer's perception of the product's quality.False

Numerous studies in sensory marketing show that packaging material, weight, and texture significantly influence consumer perception of a product's quality, purity, and value.

The Rise of "Permanent Products": Why Are Consumers Investing in Durability?

The "throwaway culture" is ending. Consumers are tired of products that stain, crack, and need to be replaced every few years. They are actively seeking items that last a lifetime.

This consumer is leading the "anti-disposable" movement. They prefer to invest once in a high-quality "permanent product" made of steel, glass, or ceramic over a disposable plastic item. A plastic-free purifier is an investment, not just a purchase.

Designing for Permanence, Not Obsolescence

This is a huge opportunity for skilled designers. For decades, we designed plastic parts for planned obsolescence. We knew the plastic would yellow, the tabs would snap, and the finish would wear off. Now, the challenge is the opposite: design for permanence8. How do you design a stainless steel housing that can be easily disassembled for cleaning? How do you design a glass pitcher with a protective, removable silicone base? These are exciting new problems. It requires a shift from thinking about draft angles and cycle times for plastic to considering sheet metal bending, deep drawing, glass molding, and welding. It's a return to classic engineering principles, and it's where a good designer can really show their value. This isn't just about making things last; it's about creating a product that becomes a trusted part of someone's home for decades.

| Design Consideration | Disposable Plastic Design | Permanent Product Design |

|---|---|---|

| Lifecycle | Short-term, 1-3 years. | Long-term, 10+ years, "for life." |

| Failure Points | Accepted (e.g., plastic clips breaking). | Designed out (e.g., using metal clasps, threaded fittings). |

| Repairability | Often impossible; designed to be replaced. | Designed for disassembly and part replacement. |

| Material Focus | Cost-effectiveness and speed of manufacturing. | Durability, timelessness, and repairability. |

The 'Buy It For Life' movement encourages consumers to purchase durable, high-quality products that last a long time.True

This movement is a conscious consumer trend reacting against planned obsolescence and throwaway culture, promoting sustainability and long-term value.

Plastic products are generally more durable and have a longer lifespan than those made of stainless steel or glass.False

While plastics are resistant to shattering (unlike glass), they degrade, yellow, scratch, and become brittle over time. Stainless steel is exceptionally durable, resistant to corrosion, and does not degrade.

What Do Consumers Now Demand in a Modern Purifier?

So, what does this all mean for your next project? The requirements have changed. Simply filtering water is just the baseline. The modern purifier must deliver on a whole new set of expectations.

Consumers now demand a purifier made from inert materials like glass or stainless steel. It must be easy to clean, durable, and have a design that reflects purity and sustainability. Replaceable filter elements should be the only disposable part.

The New Design Checklist

When your next water purifier project brief lands on your desk, it will look different. The marketing team won't be asking for a new color or shape for the same old plastic pitcher. They will be asking you how to deliver on this new promise of holistic purity. As the design expert, you need to be ready with answers. You should be prepared to discuss the pros and cons of 304 vs. 316 stainless steel, the challenges of molding borosilicate glass, and the best food-grade silicone for gaskets. This is your chance to lead the conversation and guide your company toward creating a product that meets the real, evolving demands of the market. It's a shift from being a plastic specialist to a holistic product design expert.

| 기능 | Old Expectation (Plastic Purifier) | New Demand (Modern Purifier) |

|---|---|---|

| Body Material | "BPA-Free" Plastic | 304 Stainless Steel or Borosilicate Glass |

| Lid/Spout | 플라스틱 | Stainless Steel, Glass, or Food-Grade Silicone |

| Filter Housing | 플라스틱 | Stainless Steel or Ceramic |

| Lifecycle | Disposable (1-2 years) | Permanent / "Buy It For Life" |

| Aesthetic | Utilitarian, colorful plastic | Premium, minimalist, timeless |

Borosilicate glass is more resistant to thermal shock than regular soda-lime glass.True

Borosilicate glass has a much lower coefficient of thermal expansion, allowing it to withstand rapid temperature changes without cracking, which is why it's used in laboratory equipment and high-end kitchenware.

304 stainless steel is the best material for all water and food contact applications.False

While 304 is an excellent and widely used food-grade steel, 316 stainless steel offers superior corrosion resistance, especially against chlorides and acids, making it even better for certain applications.

결론

Consumer expectations have shifted from "safer" plastic to no plastic. As designers, we must now master inert materials like steel and glass to create the durable, pure products people demand.

References

-

Understanding the implications of BPA-free products is crucial for making informed choices about health and safety. ↩

-

Understanding the advantages of stainless steel can inform better design choices for health-conscious consumers. ↩

-

Exploring the benefits of ceramic can provide insights into sustainable and health-oriented product design. ↩

-

Exploring the impact of microplastics can help consumers make better decisions regarding their water purification methods. ↩

-

Discovering the concept of holistic purity can enhance your understanding of consumer expectations in health-focused products. ↩

-

Gaining knowledge about 304 stainless steel can help you make informed decisions in product design for safety and quality. ↩

-

Investigating the importance of durability can help you align your designs with modern consumer values. ↩

-

Learning about designing for permanence can inspire innovative solutions that meet consumer demands for longevity. ↩