In a competitive marketplace, the "Made in the USA" label is more than just a point of origin; it's a powerful statement of quality, safety, and economic patriotism. For brands, it can be a cornerstone of their identity, and for consumers—both individual and business—it can be a deciding factor in a purchase. Clearly Filtered, a prominent name in the water purification industry, has firmly anchored its brand to this ideal. Their website and marketing materials are replete with declarations like "MADE IN THE USA WITH MEDICAL-GRADE MATERIALS" and "Built in the USA with premium, medical-grade materials."

But in today's world of intricate global supply chains, what do these statements truly mean? For B2B clients evaluating brand integrity and for D2C customers demanding transparency, the answer is crucial. This article peels back the label to provide a comprehensive look at where and how Clearly Filtered purifiers are made, revealing a sophisticated and modern manufacturing strategy that balances domestic production with global sourcing to create a best-of-both-worlds product.

Decoding the Label: The Critical Difference Between "Built In" and "Made In"

The language a company uses to describe its manufacturing is deliberate. While Clearly Filtered uses both "MADE IN THE USA" and "Built in the USA," these phrases are not always interchangeable in the world of manufacturing and regulation.

This nuance hasn't been lost on consumers, with one online forum user noting, "And they say 'Built in the USA', whatever that means; apparently, it doesn't mean manufactured in the USA."

This observation hits on a key point. Generally, a "Made in the USA" claim, as defined by the Federal Trade Commission (FTC), requires that "all or virtually all" of a product's parts and processing are of U.S. origin. It's a stringent standard that few complex products can meet.

The term "Built in the USA" or "Assembled in the USA," however, implies that the product's final and most significant transformation occurred domestically. This allows for the integration of components and raw materials sourced from other countries.

Clearly Filtered’s strategy of using both terms is a masterclass in modern marketing. It leverages the powerful consumer appeal of a domestically made product while maintaining the operational flexibility of a global supply chain. The core of their claim rests on the substantial, value-adding processes that happen right here on American soil, a practice that is both common and strategically sound in today's global economy.

A Product of Two Origins: Deconstructing the Supply Chain

To truly understand the manufacturing story of a Clearly Filtered pitcher, we must break it down into its two essential components: the pitcher itself and the all-important filter cartridge. Here, we discover two distinct supply chains that converge to create the final product.

1. The Pitcher Body: An All-American Foundation

The most visible and durable part of the product is the pitcher body. Clearly Filtered proudly states that its pitchers are made from "Medical-Grade Tritan" plastic, a material lauded for being "100% BPA & BPS Free."

This isn't just any plastic. Tritan is a specific, high-performance copolyester developed and produced by the Eastman Chemical Company. And where is this advanced material made? At Eastman's primary manufacturing facility in Kingsport, Tennessee, USA.

Independent sources confirm this, with one stating, "Made in the USA, Tritan™ is a remarkable best-in-class material on all counts."

This provides a verifiable and powerful basis for the company's claims. The structural integrity, safety, and physical feel of the product are derived from a specialized, American-made material. This domestic sourcing of the pitcher's main component is the bedrock of the "Built in the USA" promise.

2. The Affinity® Filter Cartridge: A Global Center of Excellence

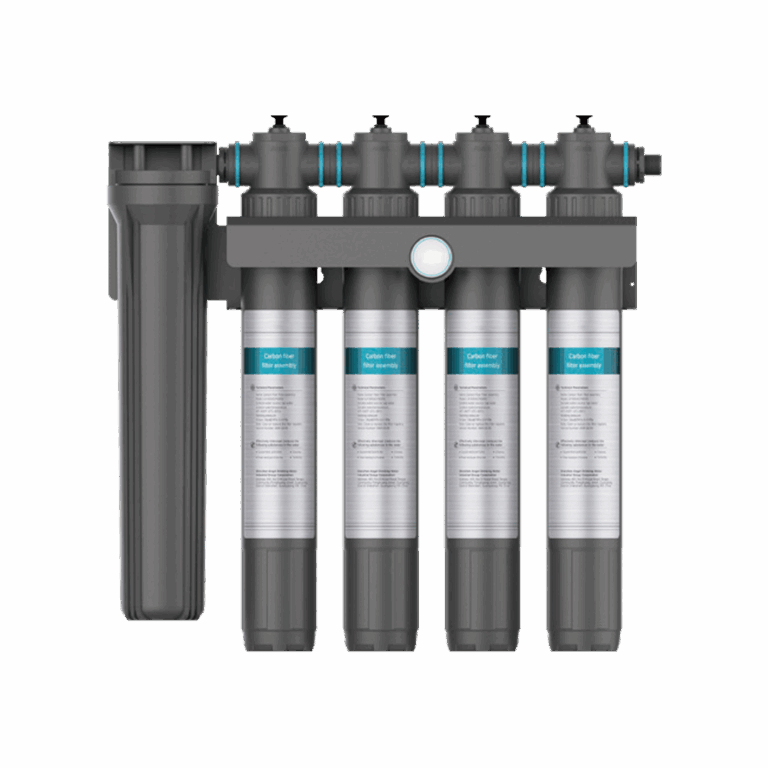

If the pitcher is the body, the filter is the heart. The disposable filter cartridge contains the company's proprietary "Affinity® Filtration Technology," the engine that does the heavy lifting of removing up to 365+ contaminants. This technology is described as a complex system involving "2 Cutting-Edge Components" and a unique blend of "6 Advanced Medias."

While the company discloses that one of these media is "granulated coconut carbon," the other five remain a trade secret. This is where the supply chain goes global. The raw materials for advanced filtration media are specialized commodities. Granular activated carbon (GAC), for instance, is produced from materials like coconut shells, coal, and wood, which are often sourced from outside the United States.

The broader water filtration industry is a complex global network, with manufacturers sourcing various types of carbon, ion exchange resins, and other media from specialized suppliers around the world.

This lack of transparency regarding the specific origins of the filter media is a strategic choice. By branding the filter's contents as a proprietary secret, Clearly Filtered is not tied to a single supplier or country. This gives them the agility to source the best-performing and most cost-effective materials from a global marketplace, building resilience and efficiency into their supply chain.

This creates a brilliant division of value. The tangible, long-term value—safety, durability, design—is anchored in the American-made Tritan pitcher. The functional, recurring value—the actual purification of water—resides in the consumable filter, which is a composite of the best materials sourced from around the globe.

The Final Assembly: How It All Comes Together in the USA

By integrating these two supply chains, we can map out the journey of a Clearly Filtered purifier from raw material to your kitchen counter:

- Global Sourcing: The process begins with procuring highly specialized filtration media, like granular activated carbon and other proprietary materials, from a network of international suppliers.

- Domestic Manufacturing: Simultaneously, the pitcher bodies are molded in the USA from Tritan plastic, which is itself manufactured in Tennessee.

- Domestic Cartridge Assembly: The globally sourced media are shipped to a U.S. facility. Here, they are blended according to the secret Affinity® formula and encapsulated within the plastic filter cartridge housings.

- Final Assembly & Quality Control: In the final and most critical domestic stage, the American-made pitchers are united with the assembled filter cartridges. They are packaged with instructions and accessories, and most importantly, undergo a final quality control inspection. This step is paramount, as one analyst notes, "Even if parts come from overseas, the final product quality and performance depend on the assembly process and quality control standards, which Clearly Filtered maintains within the USA."

- Shipping: The finished, packaged products are then shipped to customers directly from within the United States.

This hybrid model is a hallmark of modern, intelligent manufacturing. It leverages domestic strengths for the product's structure and brand identity while harnessing global expertise for its high-tech, consumable core.

What This Means for You, the Client

For the Direct-to-Consumer (D2C) Customer

The "Built in the USA" claim is a genuine promise of quality and safety. The final product is assembled and inspected by American workers. The pitcher that you handle every day is made from a premium, American-made, medical-grade material. The filter's performance, which is the reason you buy the product, is the result of a globally sourced recipe that is assembled and quality-checked domestically. You are getting a product whose final form, function, and safety are guaranteed in the USA.

For the Business-to-Business (B2B) Client

Clearly Filtered’s model is a case study in strategic sourcing and brand management. It demonstrates a commitment to a strong, marketable "Made in the USA" identity, which is a significant asset. At the same time, it showcases a resilient and cost-effective supply chain for its core technology. For retailers or distributors, this means you are partnering with a brand that has optimized its manufacturing for both marketing impact and product efficacy. The domestic final assembly and quality control provide an assurance of consistency and reliability that is critical for any business partnership.

Conclusion: A Modern Definition of "Made in the USA"

So, where are Clearly Filtered purifiers manufactured? The definitive answer is that they are assembled in the United States through a sophisticated hybrid global manufacturing model.

This process involves:

- A U.S.-manufactured pitcher body made from Tennessee-produced Tritan plastic.

- A high-performance filter cartridge containing a proprietary blend of specialized media sourced from a global supply chain.

- A final assembly, packaging, and quality assurance process that takes place entirely within the United States.

The "Built in the USA" claim is not just a marketing slogan; it's an accurate description of the final, critical, value-adding stages of production. Clearly Filtered exemplifies a paradigm shift in 21st-century manufacturing, where "American-made" is defined not by the origin of every single raw material, but by the location of design, final assembly, and the ultimate promise of quality to the customer. It's a transparent, intelligent strategy that delivers a product designed to perform at the highest level.