Launching a new product is full of unknowns. The wrong partner can cause delays and budget overruns. Choosing a partner with a proven track record1 is your best protection.

A proven OEM/ODM partner is crucial because they de-risk your entire project. They use established processes for compliance, speed, and cost control, giving you a predictable path to market and protecting your brand's reputation from day one.

Choosing a manufacturing partner is one of the biggest decisions you'll make. It's not just about finding someone who can build your product. It's about finding a team that can build your business. A partner with a proven track record brings more than just factory space. They bring experience, processes, and technology that can make the difference between a smooth launch and a costly failure. Over my years in this industry, I've seen it all. I want to walk you through the six key areas where a seasoned partner provides value that you just can't get from a newcomer. Let's look at why this choice is so critical.

How Can You Avoid Costly Delays and Recalls from Compliance Failures?

compliance failures2 can stop your launch cold. Retesting costs time and money, and recalls can destroy your brand. You need to get it right the first time.

You avoid these issues by partnering with an OEM/ODM that has an in-house, accredited lab. They test prototypes for safety, EMC, and performance before external submission, ensuring first-pass success.

I remember a client who came to us after their previous partner failed UL testing three times. They had already spent thousands on re-test fees and missed an entire selling season. It was a painful lesson for them. This is why we invested in our own CNAS-accredited in-house laboratory. Before we even think about cutting steel for tooling, we put every single prototype through the wringer. We test for everything: Clean Air Delivery Rate (CADR), noise levels, electromagnetic compatibility (EMC), and all critical safety standards. Because we do this internally, we can find and fix problems in days, not months. As a result, our products routinely clear certifications like CE, FCC, UL, and CARB on the very first try. This isn't just about saving a few thousand dollars in re-test fees. It's about guaranteeing your launch date and protecting your customers and your brand from the nightmare of a product recall.

The Cost of Compliance Failure

| 요인 | With In-House Pre-Testing | Without In-House Pre-Testing |

|---|---|---|

| Timeline | Fix issues in days | Weeks or months of delays |

| External Test Fees | Paid once | Paid multiple times |

| Launch Date | Predictable and on-schedule | At risk of being missed |

| Recall Risk | Extremely low | Significantly higher |

How Can a Proven NPI Pipeline Get Your Product to Market Faster?

Seasonal demand waits for no one. Missing a sales window for allergy or wildfire season means lost revenue. You need a partner who can move fast and with precision.

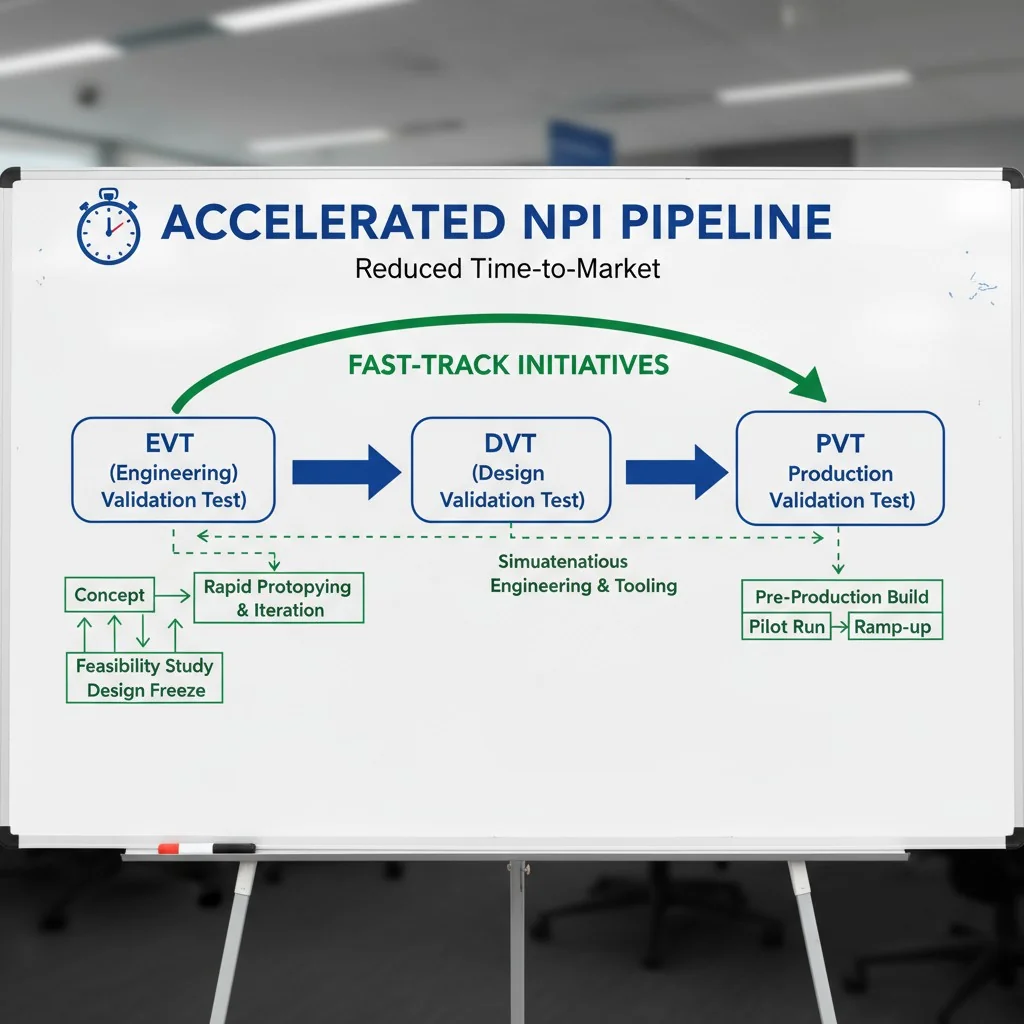

A proven New Product Introduction (NPI) pipeline compresses your timeline. An experienced partner uses a repeatable playbook (EVT-DVT-PVT) to move from concept to mass production in weeks, not months.

Time is money, but in the world of consumer electronics, time is market share. If you're launching an air purifier, you need to have inventory on shelves before allergy season hits in the spring or wildfire season starts in the summer. At HisoAir, we've spent over 20 years refining our NPI process across more than 50 successful OEM/ODM projects. We run a tight, repeatable playbook that we call EVT-DVT-PVT. This stands for Engineering Validation Testing, Design Validation Testing, and Production Validation Testing. It's a structured, phase-gated process that eliminates surprises. Each stage has clear goals and deliverables, ensuring that we don't move to the next phase until the current one is perfect. This discipline allows us to take a product brief and move it to mass production with incredible speed. For a brand that needs to react quickly to market opportunities, this accelerated timeline is a massive competitive advantage.

Typical vs. Accelerated NPI Timeline

| 스테이지 | Standard Partner Timeline | HisoAir Accelerated Timeline |

|---|---|---|

| EVT (Engineering) | 4-6 Weeks | 2-3 Weeks |

| DVT (Design) | 6-8 Weeks | 3-4 Weeks |

| PVT (Production) | 4-5 Weeks | 2-3 Weeks |

| Total Time-to-Market | 4-6 Months | 2-3 Months |

How Does Process Discipline Protect Your Unit Economics?

Your quoted cost per unit looks great on paper. But production issues, low yields, and high scrap rates can destroy your margins. You need cost predictability3 from your partner.

Strong process discipline4 locks in your unit cost. Factory automation, strict ISO 9001 quality gates, and a hyper-dense supply chain keep production efficient, so your landed cost remains stable.

When you're planning your business, you build a financial model based on a specific landed cost per unit. If that cost suddenly increases because of production problems, your entire business model can fall apart. I've seen brands get squeezed when their partner's factory has low yields, meaning a high percentage of products fail quality control5. This is where process discipline becomes your best friend. We enforce this in three key ways. First, we use factory automation for critical assembly steps to ensure consistency. Second, we live by our ISO 9001 certification, with strict quality gates at every stage of production. Nothing moves to the next step unless it passes. Third, our location in Dongguan gives us access to a hyper-dense supply chain, reducing lead times and risks for components. This combination keeps our production yields high and scrap rates low. It means the unit cost we quote you is the cost you can count on, from the first pilot run all the way to steady-state production.

The Impact of Production Yield on Profit

| Metric | 98% Production Yield | 90% Production Yield |

|---|---|---|

| Units to Produce for 10,000 Saleable Units | 10,204 | 11,111 |

| Cost of Scrapped Units (at $50/unit) | $10,200 | $55,550 |

| Impact on Gross Margin | -0.5% | -5.5% |

| Cost Stability | High / Predictable | Low / Unpredictable |

How Can You Innovate Without a Huge R&D Budget?

You need to stand out in a crowded market. But building new technology from scratch is expensive and slow. There has to be a better way to differentiate your product.

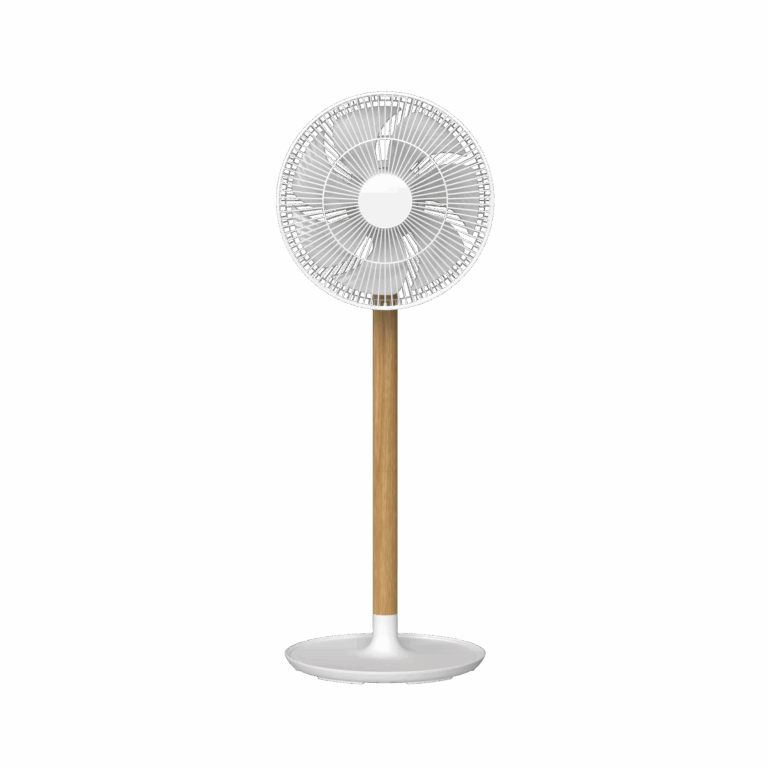

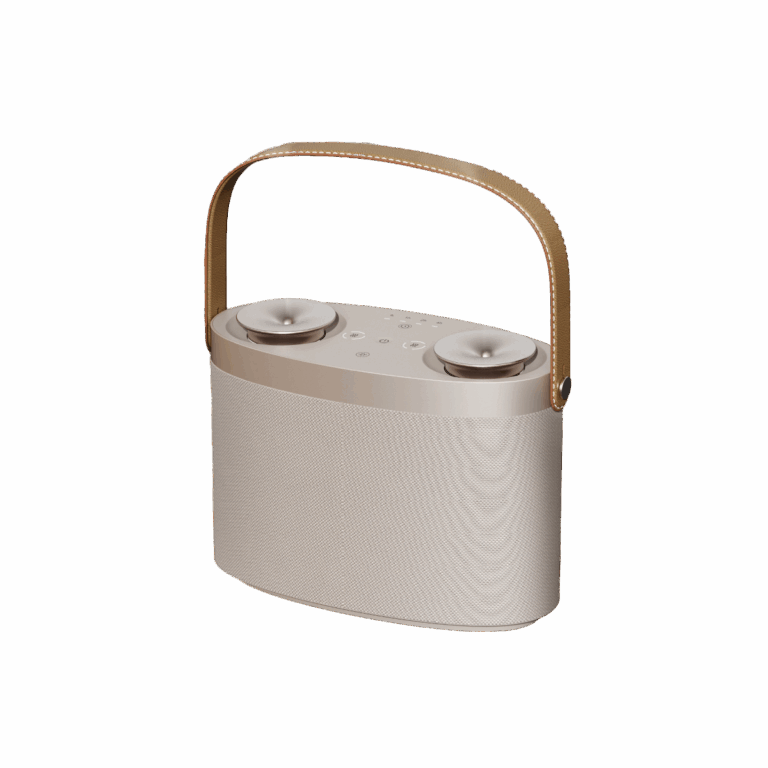

You can innovate by "plugging into" your partner's existing R&D. A good OEM/ODM offers patented technologies6, like advanced noise reduction or IoT stacks, that you can license for your product.

Most brands we work with don't have a multi-million dollar R&D department. But they still need to compete with brands that do. This is where a partnership with us becomes a powerful strategic weapon. Instead of you spending years and a fortune on ground-up research, we offer our innovations on a silver platter. We've already done the hard work. For example, we hold a patent on Decibel Cancellation™, a technology that can make a high-performance air purifier 5 to 10 decibels quieter at full power. That's a feature you can market immediately. We have an 80 m³ CADR testing chamber to validate best-in-class performance. We also have ready-to-go Integrated Sensor™ packages and complete IoT stacks for smart, app-connected devices. You can license these technologies and "plug them into" your next SKU. This allows you to launch a highly differentiated, premium product without the massive upfront R&D spend and risk.

Build vs. License: A Comparison

| 요인 | In-House R&D (Build) | Licensing from Partner (Buy) |

|---|---|---|

| Upfront Cost | $500k - $2M+ | $0 (or small licensing fee) |

| Time to Market | 18-24 months | 0-2 months |

| Technology Risk | High (May not work) | Low (Already proven) |

| Result | One proprietary feature | A suite of market-ready features |

How Does Geo-Diversified Manufacturing Protect You From Global Shocks?

Global supply chains are fragile. A single tariff, port closure, or regional lockdown can halt your entire production line. Your business is exposed to huge risks you can't control.

geo-diversified manufacturing7 is your insurance policy. Having parallel production lines in different countries lets you shift orders to avoid disruptions and maintain a steady supply of products.

The last few years have taught everyone a hard lesson about supply chain risk. A trade war can impose a 25% tariff overnight. A pandemic can lock down a major port for weeks. These events are outside your control, but they can put you out of business if you have all your eggs in one basket. This is why we made the strategic decision to build a geo-diversified manufacturing footprint. We don't just have our main hub in China. We have parallel production lines ready to go in Vietnam, Thailand, and Malaysia. What does this mean for you? It means flexibility and security. If a new tariff hits products from China, we can reroute your production to Vietnam. If a port in Thailand gets congested, we can shift to Malaysia. The best part is that we maintain identical quality documentation and processes across all facilities. You get the same high-quality product, just from a different location, protecting you from shocks that could cripple your competitors.

Managing Supply Chain Risks

| Risk Event | Single-Country Partner | HisoAir (Geo-Diversified) |

|---|---|---|

| New Trade Tariff | Production cost increases 25% | Reroute production to unaffected country |

| Port Congestion | Shipments delayed 4-6 weeks | Shift to a different country's port |

| Regional Lockdown | Production halts completely | Activate parallel production line |

| Supply Chain Status | Fragile | Resilient |

How Can Your Partner's Reputation Build Confidence in Your Brand?

Big retailers and buyers are skeptical of new brands. They want proof that you can deliver quality products at scale. Your word alone is often not enough to convince them.

Your partner's blue-chip references transfer credibility to you. When you can show you're manufactured by the same company that supplies brands like Levoit, buyers feel confident in your capabilities.

Imagine you're a buyer for a major retailer like Target or Best Buy. Two new air purifier brands pitch you. Both have a great-looking product. Brand A says, "We're a new company, and we found a factory to make our product." Brand B says, "Our product is manufactured by HisoAir, the same OEM/ODM partner behind major brands like Levoit and other Fortune 500 programs." Which brand inspires more confidence? It's Brand B, every time. This is the power of transferred credibility8. When you partner with us, our track record becomes part of your story. You're not just a startup; you're a startup with a world-class manufacturing engine. This is incredibly powerful when you're talking to retailers, government procurement officers, or healthcare buyers. They have a checklist, and "proven ability to ship quality products at scale" is always near the top. Our history of shipping for blue-chip clients is the case study that proves you can deliver.

The Power of a Credible Partner in a Sales Pitch

| Pitch Element | With Unproven Partner | With HisoAir as Partner |

|---|---|---|

| Manufacturing Quality | "We have a good QC process." | "We use the same ISO 9001 lines as Levoit." |

| 확장성 | "We believe we can scale." | "Our partner ships millions of units annually." |

| Risk for Buyer | 높음 | 낮음 |

| Buyer Confidence | 낮음 | 높음 |

결론

Choosing the right OEM/ODM partner is a strategic move. It ensures your product launches on time, on budget, and with the quality and credibility needed for long-term success.

References

-

Understanding the significance of a proven track record can help you choose a reliable manufacturing partner. ↩

-

Learning about compliance failures can help you avoid costly mistakes during product development. ↩

-

Learning about cost predictability can help you manage your budget effectively during production. ↩

-

Exploring process discipline can show you how to maintain cost predictability and quality in production. ↩

-

Exploring quality control processes can reveal how they affect product reliability and brand reputation. ↩

-

Understanding the benefits of patented technologies can give your product a competitive edge. ↩

-

Learning about geo-diversified manufacturing can help mitigate risks in global supply chains. ↩

-

Understanding transferred credibility can enhance your brand's appeal to retailers and buyers. ↩