Feeling lost in the global manufacturing maze? A wrong turn could doom your product launch. I'll give you the C-suite map to navigate production and dominate the market.

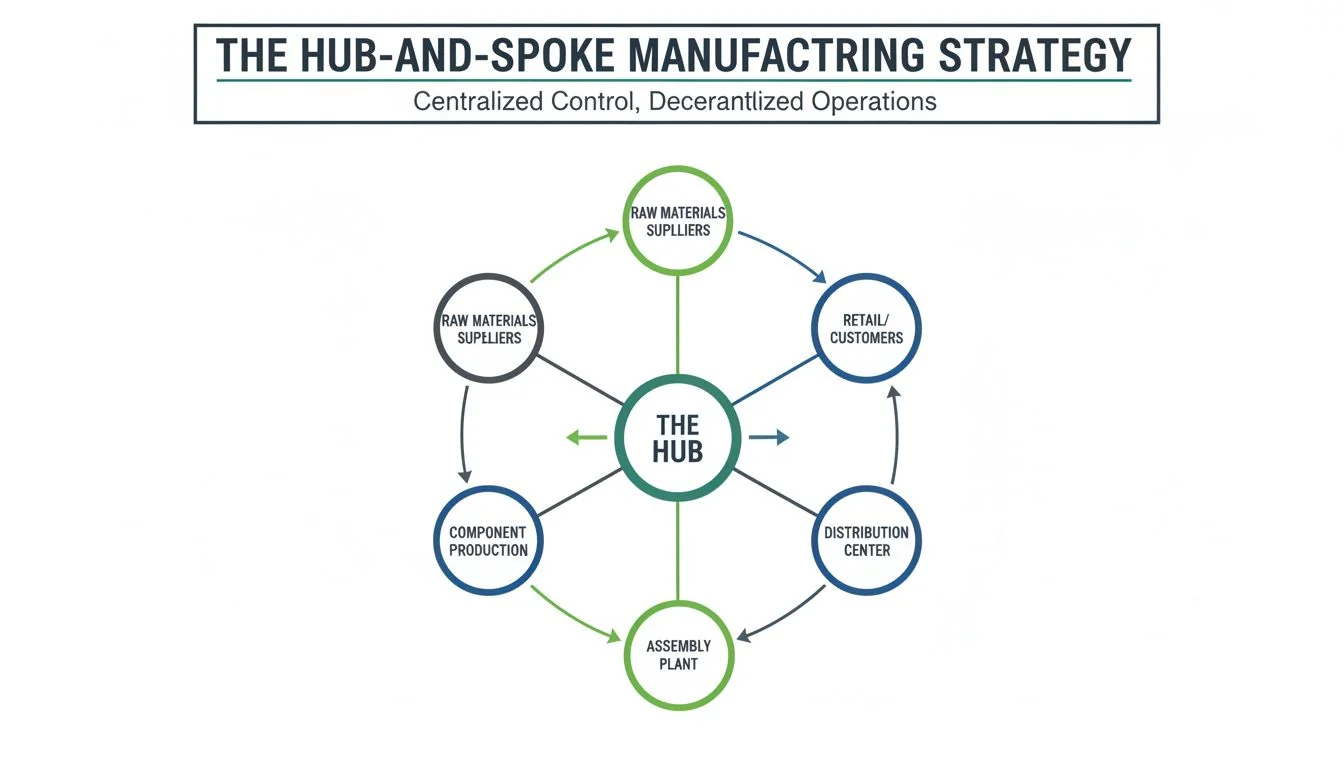

Leading wellness brands don't just pick a country. They use a "hub-and-spoke" model. They innovate in R&D hubs like China's Pearl River Delta and assemble in diversification hubs like Vietnam or Malaysia. This strategy balances innovation with supply chain resilience1.

The 'China+1' strategy means moving all manufacturing out of China.False

China+1 is a diversification strategy. It often involves adding capacity in a second country (like Vietnam or Mexico) while maintaining complex R&D and manufacturing in China.

Market risk is often a greater threat to a new product than supply chain risk.True

A product that fails to sell due to lack of innovation or market fit is a 100% loss, regardless of how secure its supply chain was. Innovation mitigates this primary risk.

You've probably heard the term "China+1" a thousand times. It's the topic of every supply chain seminar and boardroom discussion. But I've found that most people misunderstand what it really means. They see it as a simple choice: "Should I stay in China or move to Vietnam?" This is a dangerously limited view. It treats the world like a menu of interchangeable, low-cost countries. The most successful brands I work with know the truth. The map isn't a list of places; it's a system of roles. To win in 2025, you must stop thinking about finding a dot on the map and start acting like the mapmaker. But to truly understand it, you need to stop thinking about dots on a map and start thinking about roles in an ecosystem. Let's break it down.

Why Is the "Map" Not What You Think It Is?

Looking at a world map to pick a factory? That's a rookie mistake. This simple view ignores crucial regional roles, leading to costly errors. Let's redraw the map by function.

The manufacturing "map" isn't a list of countries. It's an ecosystem of specialized hubs. Each region—from Japan to Vietnam to China—plays a distinct role. Understanding these roles is the key to a successful product launch, not just picking a location based on cost.

For years, I've seen designers like you, Jacky, get stuck on the question "Where?" Should it be China? Vietnam? Mexico? This is the wrong first question. The real question is "What?" What are you trying to achieve? Are you launching a groundbreaking product or scaling a proven one? The map isn't flat. It's a dynamic ecosystem. You need to be the mapmaker, not just a dot on the map. This means you understand the entire global system and how to use it. Many brands are worried about geopolitical risk2. They want to de-risk their supply chain. But I always remind them of a bigger danger: market risk. The risk of launching a generic, "me-too" product that nobody wants. True de-risking comes from innovation, from creating something the market can't ignore. That's why understanding the ecosystem roles is so critical.

The 'China+1' strategy means moving all manufacturing out of China.False

China+1 is a diversification strategy. It often involves adding capacity in a second country (like Vietnam or Mexico) while maintaining complex R&D and manufacturing in China.

Market risk is often a greater threat to a new product than supply chain risk.True

A product that fails to sell due to lack of innovation or market fit is a 100% loss, regardless of how secure its supply chain was. Innovation mitigates this primary risk.

Admiring the flawless quality of Sony or Samsung devices? You want that same perfection. But their elite factories are walled gardens, inaccessible to outsiders. Let's see what we can learn.

Yes, Japan and South Korea are premium hubs known for incredible quality and brand prestige. However, their top-tier manufacturing is vertically integrated. It primarily serves domestic giants like Panasonic, Sony, and LG. For new brands, they are benchmarks for quality, not practical innovation partners.

I have immense respect for the manufacturing prowess of Japan and South Korea. When I started in this industry, I studied their methods relentlessly. They are masters of quality control and brand building. Think of brands like Panasonic, Sharp, or Cuckoo. Their products are exceptional. But here's the reality I learned: their ecosystem is largely self-contained. Their best factories, engineers, and designers are part of a vertically integrated system that serves their own domestic champions. They aren't set up to be innovation partners for a Canadian or American brand launching a new device. They are, in essence, inaccessible. So, what is their role on our new map? They are the "premium brand hubs3"—the gold standard we aspire to.

| Feature | Japan & South Korea | Your Strategy |

|---|---|---|

| Primary Role | Vertically Integrated Brands | Set Quality Benchmarks |

| Accessibility | Low for external brands | Observe, don't engage directly |

| Strength | Brand prestige, final product quality | Inspiration for design and UX |

Any foreign company can easily partner with top-tier Japanese electronics manufacturers.False

Top Japanese and Korean manufacturers like Sony or Samsung are highly vertically integrated. Their core manufacturing capacity is reserved for their own products, making partnerships with new external brands very difficult.

Japan accounts for over 50% of the global supply of high-precision machine tools.True

Japan is a world leader in producing the foundational machinery and components, like high-precision machine tools and robotics, that power global manufacturing.

Why Are Vietnam, Thailand & Malaysia the "Assembly & Diversification Hubs"?

Everyone is talking about moving production to Vietnam. It seems like the smart "China+1" play. But jumping there with an unproven design is a recipe for disaster. Let's clarify their role.

These countries are "Assembly & Diversification Hubs4" because they offer skilled labor, favorable costs, and growing infrastructure. They are brilliant for assembling mature products at scale. However, their R&D and complex component supply chains are less developed, making them challenging for ground-up product innovation.

Let me be clear: the rise of Southeast Asia is a fantastic development for global manufacturing. I've worked with excellent partners in Vietnam and Malaysia. They are world-class at assembly. When you have a mature product, a locked-in design, and a clear bill of materials, they are the perfect partners for diversification and scaling. But their strength is assembly, not deep-level R&D. The ecosystem for rapid prototyping, specialized component sourcing, and complex tooling is still developing. For example, think about a new product I've seen gain traction: a hygienic, all-stainless-steel humidifier. This isn't a simple plastic box. It requires deep-draw stamping, precision welding, and specialized polishing of stainless steel—all while integrating complex electronics. You can't just send a CAD file to an assembly hub and expect success. The tooling, material science, and process expertise aren't concentrated there. They are assemblers, not originators.

Vietnam can replace China's entire manufacturing ecosystem for complex electronics.False

While Vietnam is a growing hub for assembly, it lacks the vast, integrated supply chain for specialized components, materials, and rapid R&D found in China's manufacturing clusters like the Pearl River Delta.

In 2023, Vietnam's electronics exports were valued at over $100 billion, making it a major global player in electronics assembly.True

Vietnam has become a critical hub for major tech companies like Samsung and Apple for the final assembly of their products, highlighting its strength in large-scale production.

What Makes China's Deltas the "Innovation & R&D Hub"?

Geopolitical news makes you nervous about manufacturing in China. But ignoring it means missing out on the world's fastest and most complete product development ecosystem. Let's look past the headlines.

China's Pearl River and Yangtze Deltas are the "Innovation & R&D Hub5" because of their unmatched concentration of factories, component suppliers, skilled engineers, and rapid prototyping capabilities. This dense ecosystem allows for iterating and launching complex, innovative products faster than anywhere else in the world.

This brings us to the heart of the modern manufacturing map. When I started my own company, I built it in the Pearl River Delta for one reason: speed of innovation. This region is not just a country; it's a hyper-concentrated ecosystem. Within a few square kilometers, you can find a mold maker, a PCB supplier, a specialized materials expert, and a prototyping shop. This is why it's the "Innovation & R&D Hub." Let's go back to that stainless steel humidifier. To build it, you need a toolmaker who understands deep-draw metal stamping. You need a supplier for medical-grade 304 stainless steel. You need an electronics engineer to design a waterproof, high-frequency ultrasonic board. In the Pearl River Delta, I can get prototypes of all these parts in days, not months. We can sit in a room—the toolmaker, the electronics guy, and me—and solve a problem in an afternoon. This speed of iteration is impossible to replicate in a less-concentrated region. This is where you invent.

Shenzhen produces 90% of the world's consumer electronics.False

While Shenzhen is a massive hub, this figure is an exaggeration. It is more accurately described as a key hub for electronics manufacturing, producing a significant percentage of many categories, but not 90% of all global electronics.

The Pearl River Delta's GDP is larger than that of Indonesia, a G20 country.True

The Greater Bay Area (including the Pearl River Delta) has a massive economy. Its GDP exceeds that of many developed and large developing nations, highlighting its economic power and concentration of industry.

How Do You Use the "Hub-and-Spoke" Model Like a Leading Brand?

You're told to adopt a "China+1" strategy. But a poorly executed plan can fracture your supply chain. Let me show you the elegant "Hub-and-Spoke" model smart brands use.

The "Hub-and-Spoke" model uses China as the "Innovation Hub" for R&D, tooling, and initial production. Once the product is mature and processes are stable, you duplicate assembly lines to "Spoke" locations in Southeast Asia for diversification and scale. This is the C-suite strategy.

This is the strategy I implement with my most sophisticated clients. It's not about "leaving China." It's about using China intelligently. Think of it like this:

The Hub: China's Innovation Deltas

This is where your project is born. You work with a partner like me to go from idea to a market-ready product. This phase includes:

- Rapid R&D: Fast-paced design iterations.

- Tooling & Molds: Creating the core manufacturing assets.

- Pilot Production: The first small-scale run to iron out all the kinks.

- Component Sourcing: Establishing the supply chain for all the complex parts.

The Spokes: Southeast Asia's Assembly Hubs

Once your product is proven and your manufacturing process is stable, we execute the "+1". We take the established process and duplicate the assembly line in a place like Vietnam or Thailand. This is for:

- Scaling Production: Ramping up volume for a global market.

- Supply Chain Resilience: De-risking against disruption in any single region.

- Cost Optimization: Leveraging competitive labor costs for assembly.

This "Hub-and-Spoke" model is how you get the best of both worlds. You don't sacrifice innovation for safety. You achieve both.

The 'Hub-and-Spoke' model is only for giant corporations like Apple.False

Mid-sized companies can also adopt this model. By working with a strategic partner who has networks in both China (the hub) and SEA (the spokes), they can execute this high-level strategy without needing a massive internal team.

Many companies maintain R&D in one country while manufacturing in another.True

This is a common global business practice. For example, Apple designs its products in California (an R&D hub) and partners with manufacturers in Asia for production.

Your First Step Isn't "Where?" It's "Who?"

Ready to start, but overwhelmed by the map? Choosing a location is a gamble. But choosing the wrong partner is a fatal mistake. Your first step is finding the right guide.

Your first step isn't choosing a country on a map. It's choosing an innovation partner6 who understands the entire ecosystem. A partner who can help you develop a winning product in an R&D hub and then scale it intelligently across assembly hubs.

We've redrawn the manufacturing map. We've seen that Japan and Korea are benchmarks, not partners. We've seen that Southeast Asia is for assembly, not invention. And we've seen that China's deltas are the engine of innovation. The biggest risk isn't choosing the wrong country; it's launching the wrong product. The most important decision you'll make isn't "Where do I manufacture?" It's "Who will be my partner to innovate and de-risk my launch?" You need a guide who knows the terrain, a mapmaker who can help you navigate from a brilliant idea to a market-dominating product. A partner who can help you build your hub and then expand to your spokes. Before you look at a map, look for a partner. That is the first, and most important, step.

Finding a good manufacturing partner is more important than finding the cheapest location.True

A good partner prevents costly mistakes, ensures quality, and speeds up time-to-market. These benefits often far outweigh any minor savings from choosing a slightly cheaper, but less reliable, location.

All manufacturing partners in China offer the same level of service.False

There is a vast difference in quality, capability, and strategic thinking among manufacturers. Differentiating between a simple factory and a true innovation partner is critical for success.

Conclusion

The right partner is your map. They guide you from innovation in the hub to scale in the spokes, ensuring your product doesn't just get made, but wins.

References

-

Discovering strategies for supply chain resilience can help you safeguard your manufacturing processes against disruptions. ↩

-

Understanding geopolitical risk is crucial for making informed decisions about manufacturing locations and partnerships. ↩

-

Exploring premium brand hubs can provide benchmarks for quality and brand prestige in product development. ↩

-

Understanding these hubs can guide you in choosing the right locations for scaling production effectively. ↩

-

Learning about Innovation & R&D Hubs can help you identify key regions for product development and innovation. ↩

-

Finding the right innovation partner is essential for navigating the complexities of product development and scaling. ↩