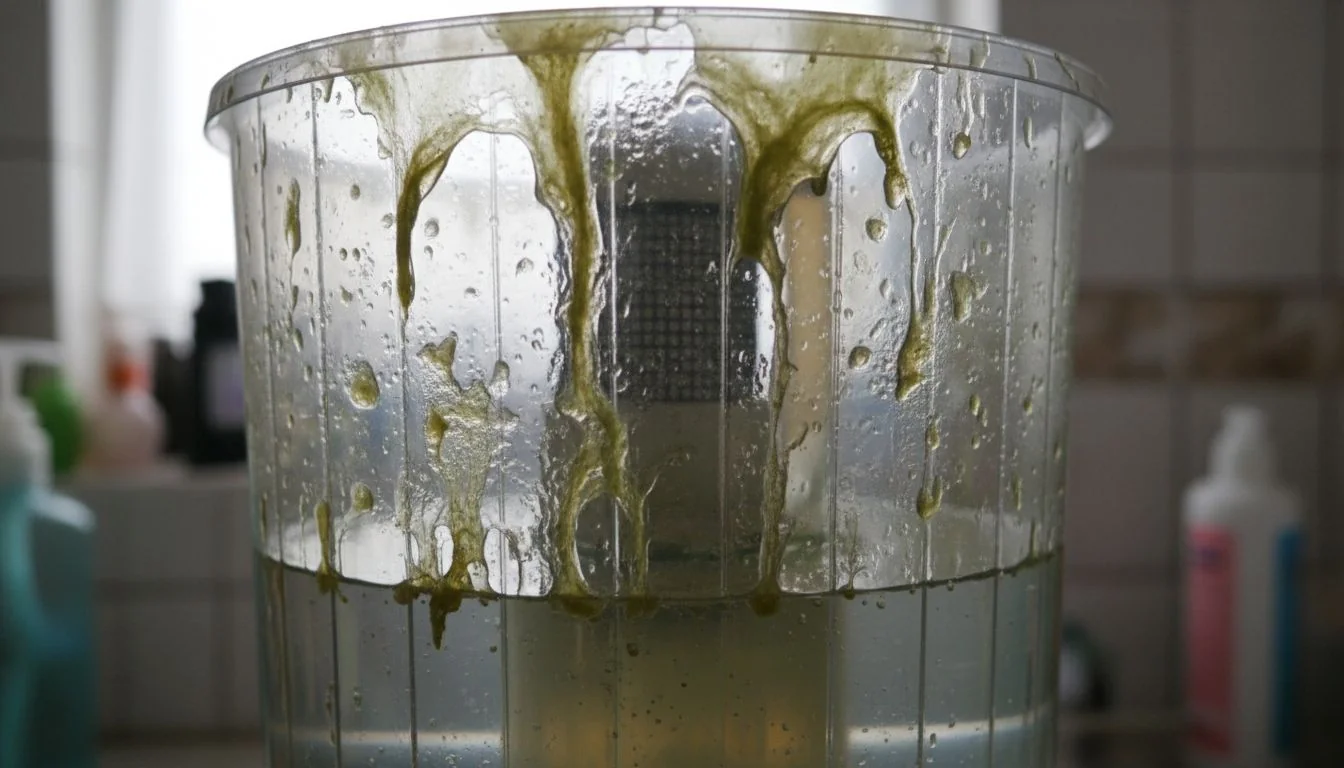

Humidifiers get slimy and gross, demanding constant cleaning. This isn't just annoying; it's a health risk. A fundamental design shift, moving beyond plastic, is finally solving this problem.

Humidifier innovation stalled at plastic because it was cheap and easy to mold for mass production. This focus on cost, however, ignored the material's inherent Hygiene problems1, creating the #1 consumer complaint that only a shift to a more challenging material like stainless steel could truly solve.

It seems like a simple appliance, right? You add water and get mist. But as any product designer like you knows, the real challenge is in the details—and especially in the Material choice2. For decades, the entire industry made a choice that seemed logical at the time, but it created a problem that has frustrated consumers ever since. It’s a choice that defined an entire era of product design.

To understand why the new wave of Stainless steel3 humidifiers is such a game-changer, we have to look back at the industry's long and complicated relationship with plastic. It's a story of good intentions, manufacturing convenience, and an "original sin" that has been hiding in plain sight.

Plastic surfaces, especially when scratched, can harbor more bacteria than non-porous materials like stainless steel.True

Micro-scratches from cleaning create tiny crevices where biofilm can form, making it difficult to fully sanitize the surface.

All plastics used in humidifiers are inherently toxic and unsafe.False

Most humidifiers use food-grade or medical-grade plastics like ABS or PP, which are considered safe for their intended use. The primary issue is hygiene and bacterial growth, not the toxicity of the material itself.

The Humidifier's Original Sin: Was Plastic the Wrong Choice from the Start?

Ever designed a product that solved one problem but created another? Humidifiers were meant to improve our air, but their core material choice introduced a new headache: constant, difficult cleaning.

The humidifier's "original sin" was choosing plastic for its water tank. While cost-effective and easy to manufacture, plastic's porous nature and susceptibility to micro-scratches create an ideal breeding ground for mold and bacteria, the number one Consumer complaint4 for decades.

Dive Deeper

When I first started in the mold-making business, plastic was king. It was a miracle material. With Injection molding5, we could create any shape imaginable, quickly and cheaply. For the burgeoning consumer appliance market, it was a perfect match. Humidifiers, once bulky and expensive, could now be mass-produced for every home. The intention was good: make healthy air accessible to everyone. But this decision came with a hidden "design debt." The very properties that made plastic great for manufacturing—its flexibility and low cost—made it terrible for hygiene. We were so focused on the initial goal of "making mist" that we overlooked the long-term consequence: "making slime." This early choice locked the industry into a path that prioritized production efficiency over user health for years to come.

| Design Aspect | The Initial Goal (with Plastic) | The Long-Term Reality |

|---|---|---|

| Cost | Make it affordable for everyone. | Achieved, but at the cost of hygiene. |

| Shape | Create complex, feature-rich designs. | Created impossible-to-clean internal parts. |

| Hygiene | Provide clean, moist air. | Created a perfect environment for bacteria. |

The term 'humidifier fever' describes a real illness caused by inhaling contaminants from dirty humidifiers.True

This flu-like hypersensitivity pneumonitis is a well-documented medical condition resulting from exposure to microorganisms aerosolized by contaminated humidifier water.

Plastic injection molding was a minor improvement in manufacturing.False

It was a revolutionary process that dramatically lowered the cost and increased the availability of consumer goods in the 20th century, enabling the mass-market appliance industry.

The "Plastic Age": A History of Good Intentions & Bad Hygiene?

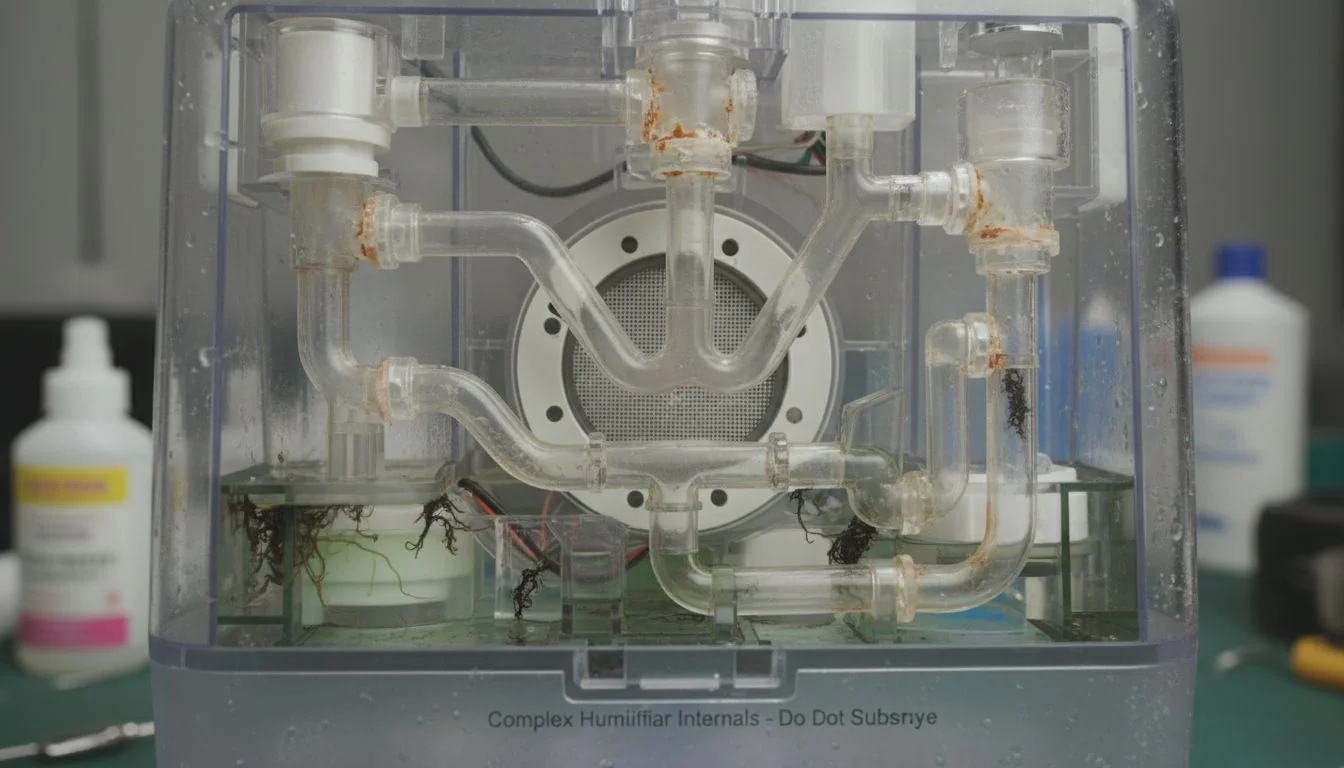

You've seen them: humidifiers with twisted water paths and tiny crevices that are impossible to clean. This wasn't a design flaw; it was a direct result of designing for plastic's strengths.

The "Plastic Age" of humidifiers prioritized manufacturing ease and cost over hygiene. Injection molding allowed for intricate, hard-to-clean internal geometries. This Design philosophy6, enabled by plastic, is the root cause of the persistent slime and mold issues that plague these devices.

Dive Deeper

As a mold designer, you know that the material dictates the design. You design for the material. With plastic injection molding, we could create complex parts with integrated features, snaps, and channels. This reduces assembly time and cost, which looks great on a spec sheet. I remember working on molds for consumer appliances where the main question was always, "Can we integrate this piece to save a step?" The question was never, "Can the user actually clean this part in a year?"

How Plastic Dictated Uncleanable Designs

This led to humidifiers with built-in water paths, convoluted chambers, and fixed components. These were marvels of molding efficiency but nightmares for the end-user. The very design that was celebrated in the factory became the source of the #1 consumer complaint for decades: "It's impossible to clean" and "It gets slimy too fast." This wasn't a bug. It was a direct feature of a plastic-centric design philosophy. The industry simply accepted that humidifiers were disposable, unhygienic products.

Adding a UV light feature completely solves the hygiene problem in plastic humidifiers.False

While UV-C light can kill free-floating microorganisms in the water, it does not remove or penetrate the slimy biofilm already attached to the plastic surfaces, which can continue to grow.

Biofilm is a slimy layer of microorganisms that adheres to surfaces and is notoriously difficult to remove.True

This protective matrix shields bacteria and mold from disinfectants and cleaning, making it a persistent problem on the porous and scratched surfaces of plastic water tanks.

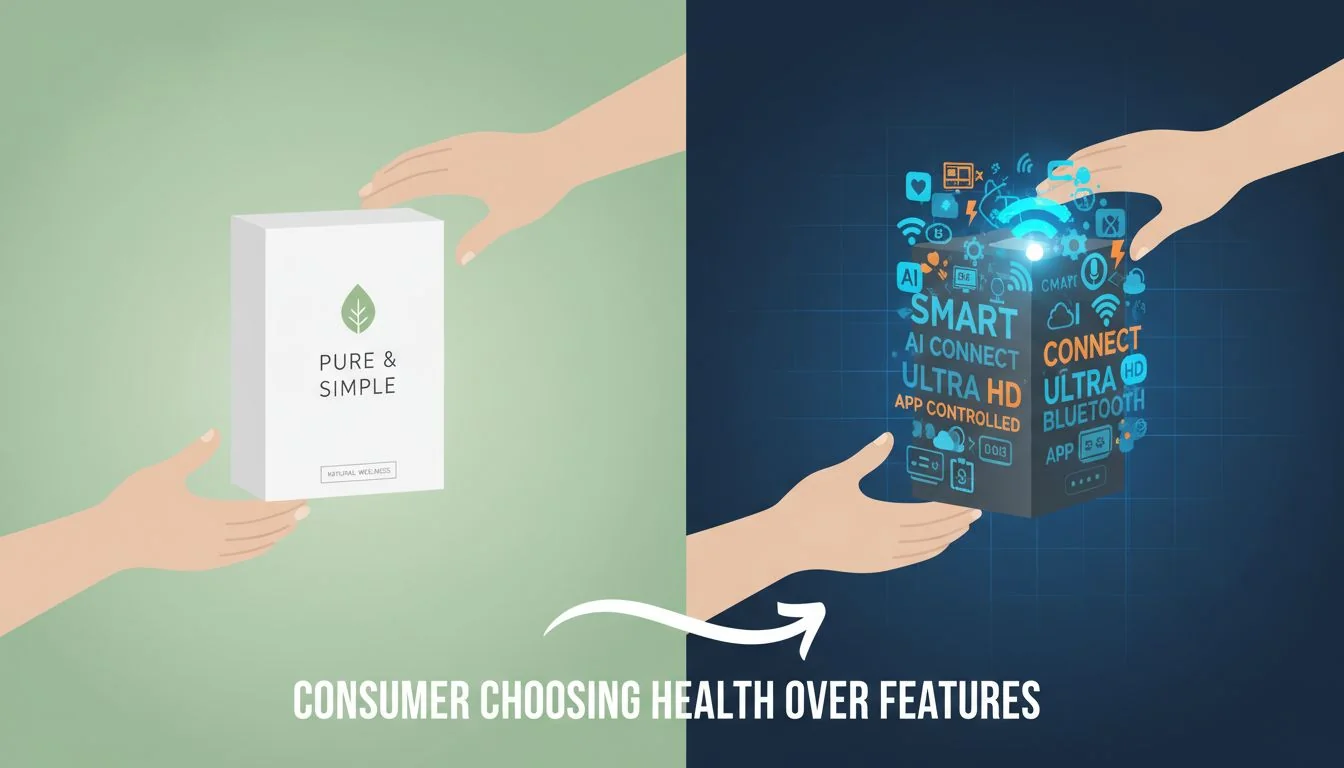

The Consumer Tipping Point: Demanding "Health" Over "Features"?

Tired of smart features on a dumb, unhygienic product? Consumers are finally pushing back, realizing that a healthy home starts with hygienic materials, not just another flashy app.

The consumer tipping point occurred when the novelty of "smart" features like apps and LED lights could no longer mask the fundamental hygiene problem. Consumers began prioritizing the Health implications7 of the device's material over superficial tech, creating a market demand for a truly cleanable solution.

Dive Deeper

For years, the industry's answer to the hygiene problem was distraction. Instead of fixing the core issue, brands added more features. Your humidifier can't be cleaned? Well, now it has an app! It still gets slimy? But look, it has a cool blue LED light! As designers, we're often pushed to add these bells and whistles. But a shift is happening, especially as people become more health-conscious.

The Illusion of Innovation

Consumers are getting smarter. They're realizing that an app can't clean slime and a mood light doesn't stop mold. They're asking a more fundamental question: "What is this thing made of?" This is where true innovation now lies. It's not in the code; it's in the material science. For a designer like you, this is a huge opportunity. It's a chance to stop adding superficial features and start solving the real problem.

| Type of Innovation | Examples | Impact on Hygiene |

|---|---|---|

| Superficial | App Control, Mood Lighting, Digital Display | None. Distracts from the core problem. |

| Fundamental | Material Science (e.g., Stainless Steel) | Solves the core problem of cleanability. |

The global wellness market has seen significant growth as consumers invest more in products for a healthy home.True

Reports from major firms like McKinsey show a multi-trillion dollar market with a strong consumer focus on air quality, clean living, and preventative health, especially post-pandemic.

Most consumers base their humidifier purchase solely on the number of smart features.False

While features are a factor, user reviews and market research consistently show that ease of cleaning and hygiene are primary drivers of both purchase decisions and long-term satisfaction.

The Breakthrough: Is Stainless Steel a Design & Health Revolution?

Imagine a humidifier you could clean as easily as a kitchen pot. No more special brushes, no more scrubbing tiny crevices. This isn't a dream; it's the reality of stainless steel.

Stainless steel is a breakthrough because it's non-porous, durable, and easy to sanitize, directly solving plastic's hygiene failures. Its adoption represents a shift in design philosophy from "cheap and complex" to "durable and clean," revolutionizing both the user experience and the product's health impact.

Dive Deeper

The solution to the humidifier's original sin was right in our kitchens all along. We use stainless steel for cookware, food prep surfaces, and surgical tools for a reason: it's incredibly hygienic. It has a non-porous surface, meaning there's nowhere for bacteria to hide. It doesn't get the micro-scratches that plague plastic. You can wipe it clean, put it in the dishwasher, or even boil it for perfect sterilization.

A Material-First Design Philosophy

When you start with steel, it forces a better design. You can't easily mold the complex, integrated shapes that you can with plastic. And that's a good thing. It pushes designers toward simpler, more open, and more accessible forms. The result is a product that is not only easier to clean but also more beautiful and durable. This is the path that pioneers like Hisoair are forging, rethinking the product from the material up.

| Feature | Plastic (ABS/PP) | Stainless Steel (304) |

|---|---|---|

| Surface | Porous, scratches easily | Non-porous, scratch-resistant |

| Cleaning | Difficult, requires brushes | Easy, wipe or dishwash |

| Biofilm8 Risk | High | Very Low |

| Durability | Can crack, discolors | High, long-lasting |

304 stainless steel is widely used in food processing and medical equipment due to its hygienic properties.True

Its chromium content creates a passive, non-reactive surface layer that resists corrosion and prevents bacteria from adhering, making it easy to clean and sanitize.

Stainless steel humidifiers are just as heavy and cumbersome as other metal appliances.False

Modern manufacturing techniques like hydroforming and stamping allow for the creation of thin, lightweight yet strong stainless steel components, resulting in a product that is both durable and portable.

Why Is This Innovation So Rare? (The Manufacturing Hurdle)

If steel is so much better, why isn't every humidifier made of it? The answer lies on the factory floor. It's difficult, expensive, and requires a completely different level of expertise.

Stainless steel humidifiers are rare due to significant Manufacturing hurdles9. Unlike cheap plastic injection molding, working with steel requires expensive tooling, specialized processes like deep drawing, and higher material costs. This high barrier to entry protects true innovators from low-quality copycats.

Dive Deeper

This is where my experience building molds comes in. The difference between making a plastic part and a steel part is like night and day. It's why this innovation is so hard to copy and so valuable.

The World of Plastic: Fast and Cheap

Plastic injection molding is a volume game. You create a mold, and you can pump out hundreds of thousands of parts quickly with relatively cheap material. The expertise is widespread, and many factories can do it.

The Challenge of Steel: Slow and Precise

Forming a seamless stainless steel tank requires a process like deep drawing or hydroforming. This involves massive, multi-ton presses and incredibly expensive, hardened steel dies. The process is slower, the material costs more, and there's a high risk of parts tearing or wrinkling if the engineering isn't perfect. As someone who has built tools my whole life, I can tell you that making a tool for plastic is a different universe than making one for deep-drawing steel. The forces, the tolerances, the material science—it's a whole other level of engineering. This difficulty is a moat. It's what separates the pioneers from the followers.

The tooling cost for deep-drawn stainless steel parts can be many times higher than for comparable plastic injection molded parts.True

Steel forming dies must withstand immense pressure and are made from hardened tool steels, requiring precision machining and extensive R&D, which drives up the initial investment significantly.

Any factory that can mold plastic can easily switch to manufacturing stainless steel components.False

Metal forming is a fundamentally different discipline requiring different machinery (presses vs. injection machines), different engineering expertise (sheet metal formability vs. polymer flow), and different quality control processes.

How Can D2C Brands Lead This "Hygienic Revolution"?

Big, established brands are often slow to change, stuck in their old plastic supply chains. This creates a massive opportunity for agile D2C brands10 to lead the market with a truly superior product.

D2C brands can lead this revolution by partnering with pioneering manufacturers who have mastered stainless steel. By using a "narrative control" strategy, they can educate consumers on the benefits of material science, positioning their brand as the healthy, modern alternative to the outdated plastic competition.

Dive Deeper

For a D2C brand or a product designer like you, this is the moment to make a mark. You don't have to play the old game of adding more features. You can change the game itself.

Seizing the Narrative

The strategy is simple: tell the story. Your story is "Plastic is the past; Steel is the future." Educate your customers. Show them the slimy inside of a plastic tank versus the pristine surface of a steel one. Frame your product not as another humidifier, but as the solution to the humidifier problem. You are selling health, cleanliness, and durability, not just moist air.

Finding the Right Partner

This revolution isn't something you can do alone. You need a manufacturing partner who has already solved the hard engineering problems of working with steel. You're not just buying a product from them; you're buying their expertise, their investment in tooling, and their years of R&D. This partnership becomes your defensible competitive advantage. It allows you to offer a product that low-quality competitors simply cannot copy, giving you the foundation to build a powerful, lasting brand.

D2C brands often succeed by serving consumer frustrations that larger corporations overlook.True

Their agile structure allows them to quickly respond to market shifts, like the growing demand for healthier home products, and build a brand story that resonates deeply with a target audience.

A great marketing story is the only thing a D2C brand needs to succeed.False

While marketing is crucial, long-term success depends on a genuinely superior product. A defensible product based on hard-to-copy innovation provides the foundation upon which a strong brand is built.

Conclusion

The shift from plastic to stainless steel is a revolution in humidifier design, prioritizing health and durability. True, defensible innovation isn't just a feature; it's in the material itself.

References

-

Understanding the hygiene issues with plastic humidifiers can help consumers make informed choices for healthier living. ↩

-

Investigating material choices in humidifier design can lead to better products that prioritize user health. ↩

-

Discovering the advantages of stainless steel can inform consumers about healthier and more durable humidifier options. ↩

-

Exploring consumer complaints can reveal critical insights into product design flaws and areas for improvement. ↩

-

Learning about injection molding can provide insights into the manufacturing processes that shape consumer products. ↩

-

Exploring design philosophy can reveal how product design choices impact user health and satisfaction. ↩

-

Understanding the health risks associated with plastic humidifiers can guide consumers towards safer alternatives. ↩

-

Learning about biofilm can help consumers understand the hygiene risks associated with humidifiers and how to mitigate them. ↩

-

Understanding the challenges in manufacturing stainless steel humidifiers can shed light on the innovation process and product availability. ↩

-

Exploring how D2C brands can innovate in the humidifier market can inspire new business strategies and consumer choices. ↩