Breathing clean air often feels very good. Air filters in Vietnam give this fresh feeling at home or work. Finding the best ones helps you breathe easy. Let me guide you!

Vietnam is now an important center for making air filters, especially because of recent changes in trade. Viet Air Filters Manufacturing Corporation is a key producer. People sourcing air filters in Vietnam should think about quality, price and changing market trends. These trends really influence choices.

I explored the air filter scene in Vietnam. I was amazed by how this country rises as an important player in manufacturing. Trade tensions change the industry. Many companies move their production from China to Vietnam. This shift got me thinking about the impact on quality and cost. Local manufacturers, such as Viet Air Filters Manufacturing Corporation, rise and change to meet these challenges. I discovered how important it is to pick the right air filters for our health and environment. It is very vital.

Vietnam is a leading air filter manufacturer in Southeast Asia.True

Vietnam's growth in air filter manufacturing is driven by market demand and trade shifts, positioning it as a key player in the region.

Trade tensions with China have no impact on Vietnam's air filter market.False

Increased trade tensions with China have prompted manufacturers to explore alternatives, boosting Vietnam's air filter industry significantly.

What Factors Are Driving Air Filter Production to Vietnam?

Many companies change their air filter production to Vietnam. The story is very fascinating. Economic shifts and strategic choices play big roles. Personal experiences also add to the tale and show larger trends.

Air filter production is moving to Vietnam because of trade tensions with China, cost savings and the need for different supply sources. Companies want to reduce tariffs but maintain quality. This change helps Vietnam grow as a key manufacturing center.

Economic Factors

The creation of air filters is shifting more to Vietnam because of trade problems with China, cost savings, and a demand for varied supply chains. Businesses try to reduce tariffs while keeping good quality.

Economic reasons matter a lot in these choices. The trade conflict between the US and China pushed many producers to change their plans. It's like seeing a friendship become unfair; you start looking for new friends who offer better balance.

I remember chatting with a coworker who suddenly had to change how he sourced materials. Many firms are moving to Vietnam for its cheaper costs and closeness to China. That's the reality.

This change is not just about figures; it's about safety and peace of mind. Producers seek options that lower costs yet keep stability.

| Factor | China | Vietnam |

|---|---|---|

| Average Production Cost | Higher | Lower |

| Tariffs on Exports | High | Lower |

| Labor Costs | Increasing | Competitive |

Manufacturers seeking a balance between cost-effectiveness and efficiency are therefore looking to Vietnam as an appealing alternative.

Supply Chain Dynamics

The changes in supply chain dynamics interest me. The first time I saw the ‘China+1’ plan, it felt enlightening. Companies view Vietnam as a preferred place for production, and I get why. It offers great flexibility.

By having factories in different spots, businesses handle market changes better. It's similar to how we adjust in life - sometimes you move on to find new paths. More buyers support this idea, urging factories to consider Vietnam seriously.

Another driving factor is the evolving supply chain dynamics. The need for a more resilient supply chain has prompted companies to adopt a China+1 strategy, where Vietnam is seen as the go-to destination for relocating production facilities. This strategy enhances operational flexibility and reduces dependency on a single country.

By diversifying their manufacturing locations, businesses can also respond more effectively to shifts in market demand and regulatory changes.

Material Sourcing Challenges

But it's not all easy. Moving production to Vietnam brings challenges in getting high-quality materials. Main materials like meltblown fabric mostly come from China, increasing costs in Vietnam by around 10-15%. It’s tricky, like enjoying a fancy meal at a low cost.

Firms must balance these expenses against the benefit of dodging high tariffs while fitting new supply chain ideas. It’s a tough puzzle and I think hard about how to arrange the pieces.

Despite the benefits of relocating production to Vietnam, challenges remain in sourcing high-quality materials essential for air filter manufacturing. Key materials like meltblown fabric used for filtration still primarily come from China.

This reliance can lead to higher costs of production in Vietnam, estimated to be about 10-15% higher than manufacturing in China. Hence, manufacturers must balance these costs with the benefits of avoiding tariffs and aligning with new supply chain strategies.

Long-Term Trends

The future looks bright for Vietnam and other Southeast Asian countries in air filter making. Demand for clean air is growing so companies adjust their plans.

Simple air filter designs allow companies to move production without big problems. But complex technologies might still need skilled engineers from China. Quality is key and having skilled people is vital to keep standards high.

Looking ahead, long-term trends indicate a gradual shift in air filter production towards Vietnam and other Southeast Asian countries as the demand for cleaner air continues globally grows manufacturers are adapting their strategies while managing costs.

Multiple reasons are driving growth in Vietnamese air filter production: explore supply chain strategies1 and cost analysis of production2 for more insights.

Air filter production in Vietnam is driven by lower costs.True

Manufacturers are relocating to Vietnam due to its competitive operational costs compared to China, making production more cost-effective.

Vietnam relies solely on domestic materials for air filters.False

Vietnam still depends on China for key materials like meltblown fabric, affecting production costs despite its advantages.

Which Companies Are Leading the Air Filter Market in Vietnam?

Follow me on an adventure in the lively air filter marketplace in Vietnam. Here, local champions and international giants race to purify our air as changing trade currents sweep through.

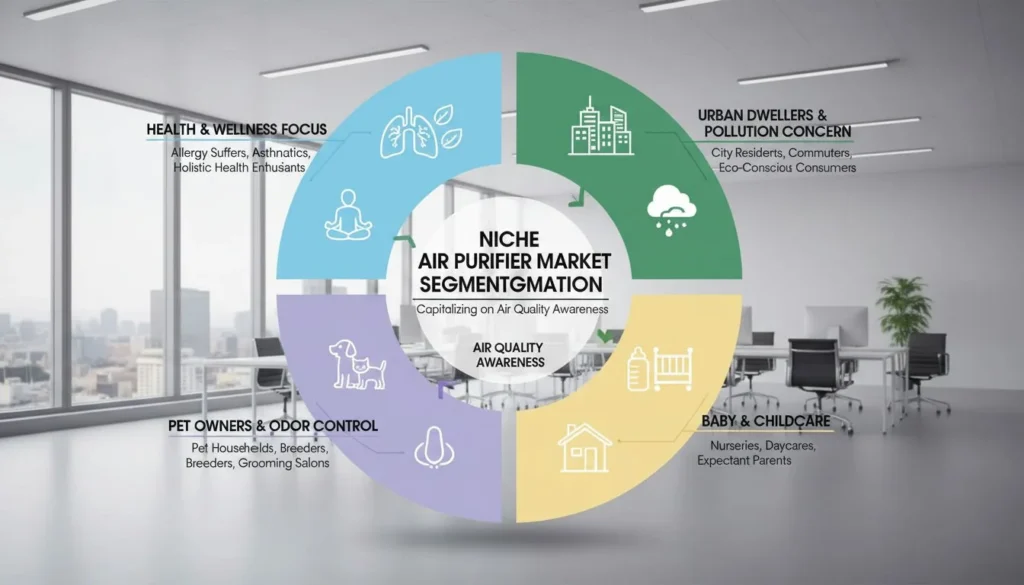

In Vietnam's air filter market, Viet Air Filters Manufacturing Corporation and HisoAir are key players. International brands like 3M are spreading due to favorable trade policies. Demand for cleaner air is rising.

Overview of the Air Filter Market in Vietnam

When I explore the air filter market in Vietnam, a wave of excitement fills me. Big changes happen quickly. Local talent and global ideas mix here. Everyone shares the dream of cleaner air in busy cities. The air filter scene buzzes with energy. Urban growth and factories demand better air quality. Many important companies rise to meet this need. Each brings something special.

Key Players in the Market

-

Viet Air Filters Manufacturing Corporation

The first time I learned about Viet Air Filters Manufacturing Corporation, I felt impressed. They started in 2008 and focus on quality air filters for homes and businesses. They show their community a strong commitment to excellence. Their goal is to offer cleaner air. Really, their dedication stands out. -

HisoAir

HisoAir stands out next. Alwen, a creative thinker, founded it. His energy for new air-cleaning tech amazes me. They care about being eco-friendly and offer unique features like Decibel Cancellation™. This effort truly distinguishes them. Curious about their goods? Definitely check out HisoAir Technologies3. -

International Brands Eye Vietnam

Trade issues and tariffs changed things a lot. Big foreign companies now see Vietnam as a good place. Companies like 3M and Honeywell aim to increase their work here. They use lower costs but keep quality high. Watching this feels like seeing a new part of Vietnam's industry start.

Market Dynamics

| Factor | Description |

|---|---|

| Trade Policies | Changes in tariffs may lead to increased foreign investment in local manufacturing. |

| Demand for Clean Air | Rising awareness of air quality issues boosts demand for effective filtration solutions. |

| Technological Advances | Innovations in air purification technology are creating more efficient products. |

Challenges Ahead

But, challenges exist as companies face obstacles in this changing world:

- Reliance on Imported Materials: Many key parts, like meltblown materials, still come from China, raising prices.

- Skill Shortage: Top-notch filters need special skills not always found locally; sometimes they work with talented engineers from China to tackle tough jobs.

Conclusion

Finishing my look at Vietnam's air filter industry, I see that learning about this competitive scene matters. Local and global companies reacting to new challenges will shape the future. Those eager to understand global market trends should explore Global Air Filter Trends4. Together, we strive for cleaner air in this essential field. Innovation leads the way.

Viet Air Filters Manufacturing Corporation was established in 2008.True

This claim highlights the founding year of Viet Air Filters, confirming its presence in the Vietnamese air filter market since 2008.

HisoAir's technology includes Decibel Cancellation™ innovation.True

This claim emphasizes HisoAir's unique technological advancement, showcasing their commitment to innovative air purification solutions.

How Does the Quality of Vietnamese Air Filters Compare to Global Standards?

When I first started looking into air filters in Vietnam, I noticed how quickly our local market is changing. The transformation is very noticeable. Let’s explore air filtration and compare Vietnamese products to international standards.

Vietnamese air filters are getting better, but different manufacturers produce varying levels of quality. Some companies reach global standards such as HEPA. Many still rely on imported materials. This dependency may impact their price and performance.

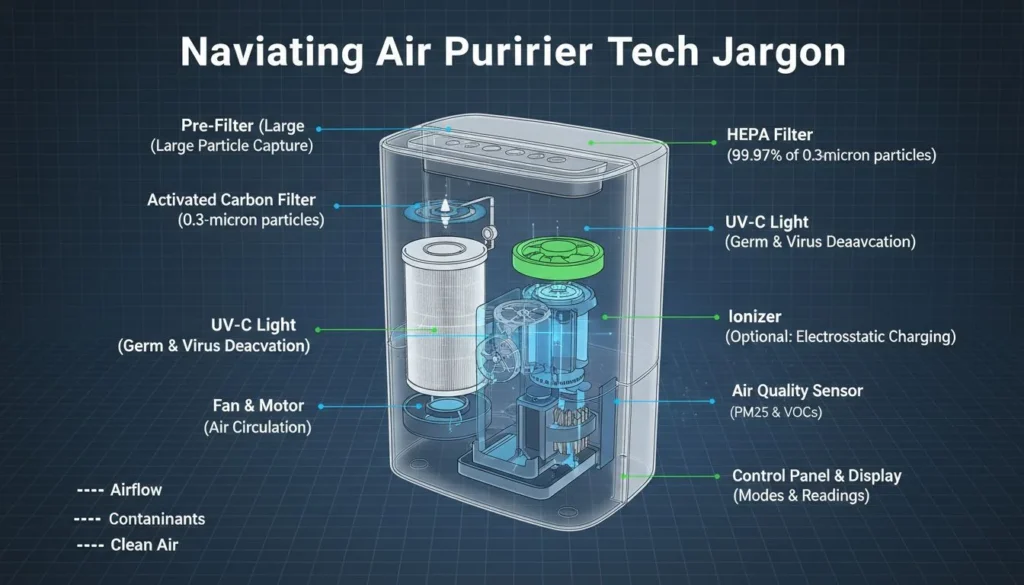

Overview of Air Filter Quality Standards

Quality standards play a big role in air filters. Standards like HEPA (High-Efficiency Particulate Air) and MERV (Minimum Efficiency Reporting Value) show how good a filter is. Filters catch very small particles, so the air we breathe stays clean and safe.

In Vietnam, more manufacturers are starting to follow these world standards. However, different filters vary in quality. Effectiveness depends on the technology used, materials, and production methods. These factors decide if Vietnamese air filters can compete worldwide. More information on filter standards5.

Current Market Landscape in Vietnam

The air filter industry in Vietnam is still growing. Firms like Viet Air Filters Manufacturing Corporation started in 2008. Vietnam is now a big place for making air filters due to recent shifts in global supply chains, especially with trade tensions between the US and China.

| Manufacturer | Year Established | Key Products | Compliance with Global Standards |

|---|---|---|---|

| Viet Air Filters Manufacturing Corporation | 2008 | Residential and Commercial Filters | Some compliance with HEPA |

| HisoAir | 2020 | High-efficiency Air Purifiers | Adheres to international standards |

With factories coming to Vietnam, quality will probably improve as manufacturers adopt better technologies and practices. For insights into the market dynamics, check out Vietnam’s manufacturing growth6.

Challenges Faced by Vietnamese Manufacturers

I learned that Vietnamese manufacturers face obstacles in reaching top global standards. Key materials like meltblown fabric mostly come from China, which increases production costs.

Creating advanced systems needs special engineering skills. Local companies struggle to innovate.

| Challenge | Description | Impact |

|---|---|---|

| Material Sourcing | Reliance on imports for key filter components | Increases production costs by 10-15% |

| Technical Expertise | Need for skilled engineers for complex projects | Slower innovation and development cycles |

As air pollution rises, these challenges must be tackled directly. It's crucial for competing globally. For a deeper understanding of these challenges, visit air filter production challenges7.

Future Prospects and Innovations

I feel hopeful about the future of Vietnamese air filters as companies like HisoAir focus on innovation and sustainability. They follow market demands and international standards.

Cleaner air solutions are part of a broader movement reflecting a big shift toward caring for the environment. Companies need to invest in new technologies and eco-friendly methods to meet world standards.

- Innovation: Research and development are key for new filtration technologies.

- Sustainability: Using green materials appeals to eco-conscious consumers.

Vietnamese air filters often meet HEPA standards.False

Some Vietnamese manufacturers comply with HEPA standards, but overall implementation varies. Not all filters achieve this level of quality consistently.

Air filter production in Vietnam is growing due to global shifts.True

The relocation of factories to Vietnam has increased air filter production, driven by trade tensions and demand for better quality products.

What Should You Consider When Choosing an Air Filter Supplier in Vietnam?

Exploring air filter suppliers in Vietnam might seem confusing. But it is not too hard. I want to share important tips with you. These tips help you select the right option for your needs.

Look at the air filter supplier's reputation in Vietnam. Check their quality certifications. Evaluate how efficiently they handle their supply chain. Consider the impact of tariffs. Seek out available technical support. Form a partnership that is truly reliable.

Understanding Supplier Reputation

When I first looked into air filter suppliers, I quickly saw that the right choice could really change everything. It wasn't only about cost; it was about finding someone I could trust. I learned that reputation very much matters. While picking a supplier, I researched their credibility. I explored customer reviews and feedback, which often showed more than advertisements ever could. I even talked to colleagues in the field who had dealt with these suppliers before. These chats were priceless; they gave me a clearer view of what to expect and often pointed out problems or hidden strengths.

Quality Assurance and Certifications

Quality assurance is very crucial when dealing with air filters. Early on, I learned to check if suppliers followed global standards like ISO 9001. Seeing those certificates next to their names gave me peace of mind. It assured me that their products followed key safety and performance standards.

| Certification | Description |

|---|---|

| ISO 9001 | Quality management systems |

| ISO 14001 | Environmental management |

| CE | Compliance with EU safety standards |

I found that asking about their quality control steps was also helpful. Nobody wants to risk air quality!

Supply Chain Efficiency

In Vietnam's growing market, supply chain efficiency became vital for me. As a lot of materials are still imported from China, I had to check how well suppliers handled logistics and stock. A dependable supplier should reduce delays and deliver on time, which became very important as I expanded my business.

To better understand this, consider asking about:

- How do they get their raw materials?

- What shipping methods do they use?

- How do they manage inventory?

These details made me feel confident in their skills.

Tariff Implications and Cost Considerations

While exploring different options, tariffs came up over and over again. With recent trade tensions affecting costs, understanding these tariffs and their impact on my budget changed everything for me. Suppliers who were open about their prices were incredibly valuable.

Assessing the total cost of ownership, including shipping and potential tariffs versus the initial purchase price is crucial for long-term financial planning.

Technical Support and Expertise

I realized access to technical support really matters in deciding my satisfaction with a supplier. Air filtration systems often need expert advice, so I chose suppliers who could give that. When I found HisoAir, I admired their dedication to customer support, from setup to solving problems.

I asked questions like:

- What kind of technical help do they provide?

- Do they train for upkeep?

- Are there resources for common troubles?

Thinking about these factors, I saw choosing an air filter supplier is not just a deal; it's about creating a partnership that matches my needs in Vietnam. Armed with this wisdom, I felt ready to decide smartly, bringing cleaner air to me and my community.

Supplier reputation is crucial when choosing an air filter supplier.True

A supplier's reputation reflects their reliability and product quality, making it essential for selection.

ISO certifications guarantee the best air filter prices.False

While ISO certifications ensure quality, they do not directly correlate with pricing; quality assurance is key, not cost alone.

Conclusion

Vietnam's air filter industry is growing due to trade shifts, with local manufacturers like Viet Air Filters and HisoAir adapting to meet rising demand for clean air.

-

Explore this link for an in-depth understanding of economic impacts on air filter production, vital for industry stakeholders. ↩

-

Learn more about supply chain strategies that can optimize manufacturing processes in a competitive landscape. ↩

-

Discover insights into the top players in the Vietnamese air filter market and their strategies for success. ↩

-

Discover insights into the top players in the Vietnamese air filter market and their strategies for success. ↩

-

This link provides insights into the evolving standards for air filters globally, helping you understand what to look for when comparing products. ↩

-

Explore this link for detailed information on Vietnam's manufacturing landscape and how it affects air filter quality. ↩

-

Learn about the challenges faced by local manufacturers in meeting international air filter standards. ↩