Your brand's reputation is on the line. A bad supplier can destroy it overnight. I'll show you how to pick the right partner and protect your business.

To vet factories, you need a framework. Focus on three pillars: Social, Environmental, and Product Sustainability1. Then, demand proof of transparency through certifications, not just promises. This ensures your partner aligns with your brand's values and protects your reputation.

I've been in the mold and manufacturing business for a long time. I started on the factory floor and eventually built my own company. I’ve seen brands rise and fall, and I can tell you that many failures start with one bad choice: the wrong supplier. It’s a mistake that can cost you everything. You think you're just buying a product, but you're actually buying a partnership. Their problems become your problems. Their shortcuts become your brand's crisis. If you're building a premium brand, you can't afford to get this wrong. Let's break down what you really need to look for to make the safe choice.

Over 60% of a company's brand reputation is tied to its supply chain practices.Vrai

Studies by organizations like the World Economic Forum have shown that supply chain visibility, ethics, and sustainability are major drivers of consumer trust and brand perception.

All factory audits guarantee 100% ethical production.Faux

Audits are a snapshot in time and can sometimes be cheated. Consistent vetting and a culture of transparency are more reliable indicators than a single passed audit.

Why Does Your Brand's Reputation Depend on Your Supplier?

You spent years building a premium brand. But a hidden problem in your supply chain can create a public relations nightmare. I'll explain why your supplier is your silent business partner.

Your supplier is an extension of your brand. Today's customers don't distinguish between your company and the factory that made the product. Any ethical, environmental, or quality failure from your supplier becomes your failure, directly damaging your reputation and sales.

I once worked with a client who built a fantastic brand for kitchen gadgets. They were growing fast. They switched to a cheaper supplier to improve their margins. Six months later, a story broke online about the terrible working conditions in that new factory. My client's brand was mentioned in every article. Their sales dropped by 50% in one week. They spent the next year doing damage control. They learned a hard lesson: your supplier’s factory is your factory in the eyes of the customer.

The Customer Sees Everything

In the past, what happened in a factory stayed in a factory. Not anymore. Everyone has a camera in their pocket. Social media can turn a local issue into a global crisis in hours. Premium brands are watched more closely. Customers pay you a premium price because they expect premium quality and premium ethics. If your supplier cuts corners, your customers will feel betrayed.

Your Supplier is Your Risk or Your Shield

A good supplier protects you. They manage quality, treat their workers well, and respect the environment. They are your shield against risk. A bad supplier is a time bomb. You never know when they will explode and take your brand down with them. This is why vetting is not just a task; it's a core business strategy for any serious brand.

Companies with transparent and ethical supply chains can increase their revenue by up to 20%.Vrai

Research from institutions like MIT Sloan shows that consumers are increasingly willing to pay more for products from brands they trust, and this trust is heavily influenced by supply chain transparency.

The lowest-priced supplier is always the most profitable choice in the long run.Faux

The hidden costs of poor quality, production delays, and reputational damage from a low-cost, low-quality supplier often outweigh the initial savings.

What is "Sustainability," and Why Are There 3 Pillars, Not 1?

Everyone talks about sustainability, but most get it wrong. They focus on one area and miss the big picture. I'll give you a complete framework to use so you can see clearly.

True sustainability isn't just about being "green." It stands on three essential pillars: Social (how workers are treated), Environmental (factory impact), and Product (the lifecycle of the item itself). You must evaluate all three to be truly sustainable.

When people ask me about finding a "sustainable" factory, they usually just mean "eco-friendly." They ask if the factory uses solar panels or recycles water. Those things are good, but they are only one part of the story. A factory can have solar panels on the roof but treat its workers poorly. Or it can treat workers well but produce a product designed to be thrown away in a month. That is not sustainability. I developed a simple framework to avoid this trap. I call it the "3 Pillars." It forces you to look at the whole picture.

The 3 Pillars of True Sustainability

To properly vet a partner, you need to ask questions about all three of these areas.

| Pillar | What It Means | How to Prove It |

|---|---|---|

| Social Sustainability2 | The factory treats its workers ethically. This includes fair wages, safe working conditions, and reasonable hours. | BSCI Audit Report. This is the standard for social compliance. Ask for their latest report. |

| Environmental Sustainability3 | The factory minimizes its negative impact on the environment. This includes managing waste, pollution, and energy use. | ISO 14001 Certificate. This shows they have a certified environmental management system. |

| Product Sustainability | The product itself is designed for a long life and minimal waste. It is durable, reusable, or recyclable. | Material Choice & Design. Is it made of durable stainless steel or disposable plastic? |

This framework helps you move beyond vague marketing terms and focus on what really matters.

BSCI (Business Social Compliance Initiative) audits cover 13 performance areas, including fair remuneration and occupational health and safety.Vrai

BSCI provides a comprehensive methodology to audit a company's social compliance, ensuring workers' rights are protected according to international labor standards.

An ISO 14001 certificate means a product is made from 100% recycled materials.Faux

ISO 14001 certifies that a factory has a formal system for managing its environmental impact. It does not certify the content of the products themselves.

How Do You Pass the "Product Sustainability" Test?

Your factory might have green audits. But what if the product itself is the problem? I'll show you the one test that separates truly sustainable brands from the rest.

The test is simple: is your product designed for a long life or for the landfill? A product made from disposable plastic is inherently unsustainable, regardless of factory certifications. A durable material like stainless steel is a fundamentally more sustainable choice.

This is the pillar most brands ignore, and it's the most important one for your reputation. You can have a factory with a perfect BSCI audit and an ISO 14001 Certificate4. But if that factory is making a cheap plastic product that will break in six months and end up in the ocean, you are not a sustainable brand. You are a brand that is contributing to the problem. For a premium brand, this is a huge risk. Your customers are smart. They know that a disposable product is not sustainable.

The Material is the Message

The material you choose sends a message about your brand's values. Think about it.

| Fonctionnalité | Disposable Plastic Product | Durable Stainless Steel Product |

|---|---|---|

| Durée de vie | Short-term, single-use or limited use. | Long-term, designed for years of use. |

| Brand Perception | Seen as cheap, convenient, and wasteful. | Seen as premium, durable, and responsible. |

| End of Life | Ends up in a landfill or as pollution. | Can be used for decades and is highly recyclable. |

| Sustainability Claim | Weak. Depends entirely on factory processes. | Strong. The product itself is part of the solution. |

Choosing a material like stainless steel over plastic is not just a design choice. It is a brand strategy. It tells your customers that you value quality and longevity. It makes your product inherently more sustainable and protects your brand from accusations of greenwashing.

Stainless steel is 100% recyclable and retains its value, with nearly 90% of end-of-life stainless steel being collected and recycled.Vrai

The high content of valuable alloys like chromium and nickel in stainless steel makes it one of the most recycled materials on earth, with a very high recovery rate.

All plastics are equally harmful to the environment.Faux

While single-use plastics are a major problem, some plastics are designed for durability and can be recycled. However, the recycling rates for plastic are far lower than for metals like stainless steel.

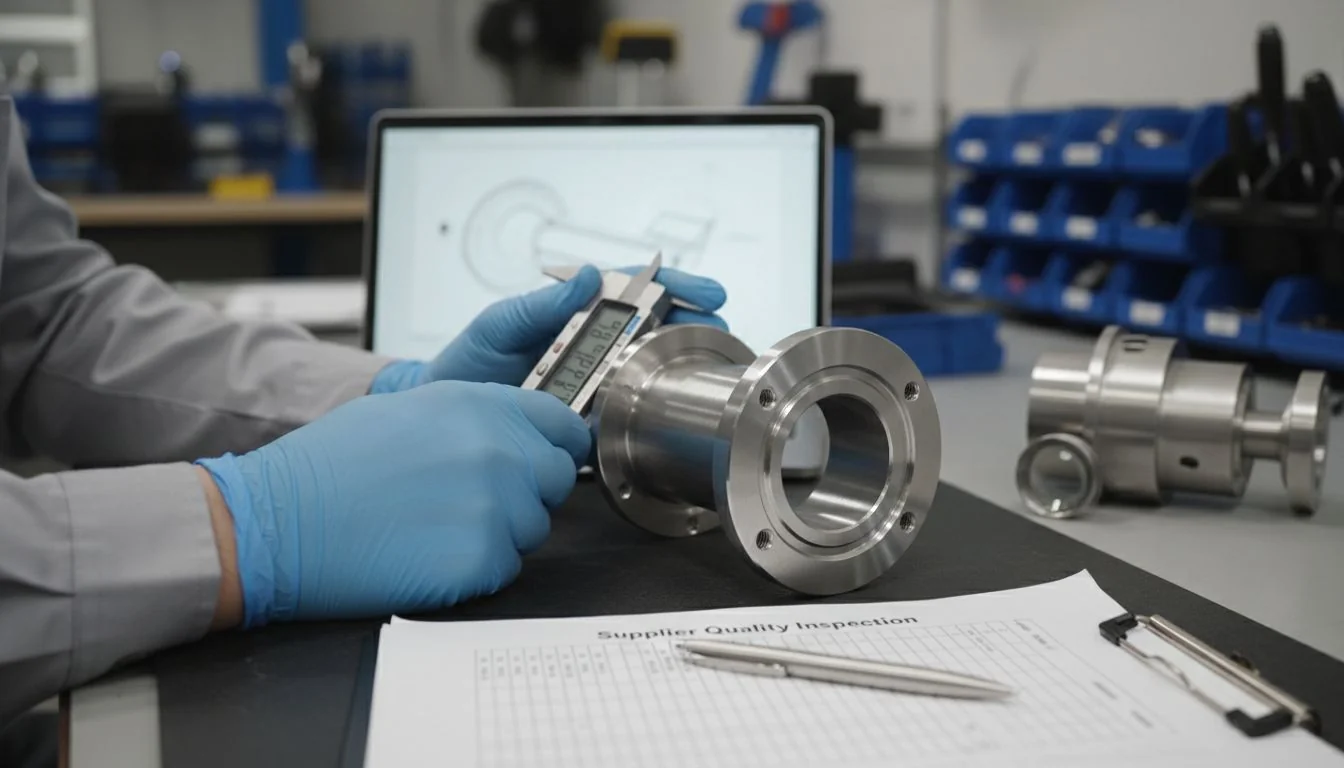

What is Real Transparency, and How Can You Prove It?

Factories love to promise "transparency." But promises are worthless without proof. I'll show you what real, provable transparency looks like on paper, so you never get fooled again.

Transparency isn't a feeling or a good relationship. It is a collection of verifiable, third-party certificates. A truly transparent partner can show you their BSCI, ISO, ETL, CARB, CE, and Conformité RoHS5 documents. No certificates means no transparency.

I've heard it all from factory owners. "Trust me." "We are very transparent." "We have a great culture." These words mean nothing. I learned early in my career that in manufacturing, the only thing that matters is what you can prove. If a factory claims they are ethical, I ask for the BSCI report. If they claim they are environmentally friendly, I ask for the ISO 14001 certificate. If they claim their product is safe for the US market, I ask for the ETL and CARB certificates. It's a very simple conversation.

Compliance is Transparency

A factory that has invested in getting these certificates is a factory that is serious about its business. They have nothing to hide. They have already done the hard work to prove they meet global standards. This is the definition of a "market-ready" partner.

Here’s what you should ask for:

- BSCI: Proves social compliance. It's your ethical shield.

- ISO 14001: Proves environmental management. It's your green shield.

- ETL/UL: Proves product safety for the North American market. It's your liability shield.

- CE: Proves product safety for the European market.

- RoHS: Proves the product is free from specific hazardous materials.

- CARB: Proves compliance with California's air quality standards, often required for products sold in the US.

A partner with this full portfolio is not just transparent; they are the safe choice. They have de-risked the entire process for you.

An ETL Listed Mark shows that a product has been tested and meets North American safety standards.Vrai

ETL (originally a mark of Intertek) is a Nationally Recognized Testing Laboratory (NRTL) in the US. The mark is proof of product compliance to published industry standards.

A CE mark is a global certification for product safety.Faux

The CE mark is specific to the European Economic Area (EEA). It signifies that a product meets EU safety, health, and environmental protection requirements, but it is not a global standard.

What is a Simple 3-Step Action Plan to Vet Any Partner?

Feeling overwhelmed by the vetting process? It's easy to get lost in details. I'll give you a simple, 3-step plan you can use immediately to find a safe and reliable partner.

First, use the 3 Pillars framework to ask the right questions. Second, demand the certificates that prove their claims (Compliance = Transparency). Third, evaluate the product's own sustainability. A partner who passes all three is a safe bet.

After decades in this industry, I've refined my vetting process into a simple action plan. It cuts through the noise and gets straight to what matters. As a product designer or brand owner, you can use this exact plan to protect yourself and your company. It turns a complicated decision into a clear choice. This is how you filter out the risky partners and find the one that will help you grow.

Your 3-Step Vetting Checklist

Use this as your guide during your next conversation with a potential factory.

-

Step 1: Ask About the 3 Pillars.

Start the conversation with the big picture. Ask them directly: "Can you tell me about your practices for social, environmental, and product sustainability?" Their answer will tell you a lot. A good partner will understand the question and have ready answers. A bad partner will be confused or give vague promises. -

Step 2: Request the Proof.

Don't just take their word for it. Follow up with a simple request: "Great. Can you please send me a copy of your current BSCI report, your ISO 14001 certificate, and the relevant product safety certificates like ETL and RoHS?" A transparent partner will provide these immediately. A factory that makes excuses is hiding something. -

Step 3: Apply the Product Test.

Finally, look at the product itself. Ask yourself: "Is this product designed to last, or is it designed to be disposable? Does this material (e.g., stainless steel) enhance my premium brand image, or does this material (e.g., cheap plastic) risk it?" Choose the partner whose product aligns with the long-term vision for your brand.

Following a structured vetting process can reduce supply chain risks by over 50%.Vrai

Studies in supply chain management show that formal, structured supplier evaluation and auditing processes significantly reduce the likelihood of quality failures, ethical breaches, and production disruptions.

You can fully vet a factory through email and video calls alone.Faux

While initial vetting can be done remotely, a physical factory visit is often crucial to truly understand a partner's capabilities, culture, and operations. It's difficult to verify everything from a distance.

Conclusion

Your supplier's choices become your brand's identity. Use this framework to vet partners thoroughly. Your reputation depends on it, so choose a partner who protects your brand.

References

-

Product Sustainability is key to ensuring that products are designed for longevity and minimal waste. ↩

-

Understanding Social Sustainability is crucial for ensuring ethical treatment of workers in factories. ↩

-

Evaluating Environmental Sustainability helps in minimizing the negative impact on the environment. ↩

-

The ISO 14001 Certificate indicates a factory's commitment to effective environmental management. ↩

-

RoHS Compliance is crucial for ensuring products are free from hazardous materials, promoting safety. ↩