Your wellness product has great specs but feels cheap, and customers won't pay a premium. Learn from appliance makers who have mastered turning engineering into perceived value.

They can learn to use material honesty1, engineer for the felt experience, design for the entire user lifecycle, and build ecosystems instead of single products. This approach builds deep customer trust and gives you permission to charge a premium price for the value you deliver.

When I started my own mold and CNC trading company, I saw countless product ideas. The ones that succeeded weren't always the most technologically advanced. The winners were the ones that felt right in the customer's hands and in their homes. They understood that the physical object tells a story long before the user manual is ever opened. For a product designer like you, this is where your work transcends simple function and becomes about communicating value. Let's break down how the best in the business do it, and how you can apply these lessons to your own designs, starting with the materials you choose.

The use of stainless steel in appliances began in the 1980s with brands like Sub-Zero and Wolf.Vrai

These brands pioneered the professional-style kitchen look for home use, using stainless steel to communicate durability and a clean, hygienic aesthetic.

All plastics used in consumer products feel equally 'cheap' to customers.Faux

The choice of polymer, texture, wall thickness, and molding quality dramatically affects perceived value. A high-gloss, thick-walled ABS part feels much more premium than a thin, flimsy polypropylene part.

Your plastic product looks like every other one on the shelf, getting lost in a sea of cheap competitors. Use material honesty and tight tolerances2 to communicate quality instantly.

By choosing materials that honestly reflect their function, like stainless steel for hygiene, and engineering tight, consistent gaps, you create a tangible sense of quality. This visible craft tells a story of durability and value that customers can see and feel, justifying a higher price.

I call this principle "Material = Message." The materials you choose are the first words your product speaks to the customer. In the wellness space, buyers are looking for hygiene, durability, and long-term value. A stainless-steel water tank in a humidifier doesn't just hold water; it communicates cleanliness and permanence. As a designer, you translate these brand promises into physical reality. This goes beyond just material selection. It's about craft and precision.

The Power of Precision

When we design molds, we obsess over tolerances. A 0.1mm difference in a gap can be the difference between a product that feels solid and one that feels flimsy. Premium appliance makers know this. They design for tight, even parting lines and consistent gaps between components. This precision isn't just for aesthetics; it's a non-verbal signal of quality engineering. It tells the user, "We cared about every single detail."

| Material Choice | Perceived Attribute | Design/Mold Consideration |

|---|---|---|

| Stainless Steel (304) | Hygienic, Durable, Premium | Stamping, deep drawing, welding. Higher tooling cost. |

| Glass | Pure, Clean, Non-reactive | Molding or casting. Fragility requires protective design. |

| High-Gloss ABS | Sleek, Modern, Solid | Requires high-polish mold (SPI-A1/A2), careful gate location. |

| Matte PBT | Soft, Technical, Resilient | Texture is applied to the mold surface. Hides fingerprints. |

Think about how you can use material honesty in your next project. If a part needs to be clean, can you use a material that is inherently so? If the product is handled daily, can you use a material that feels substantial and durable? This is how you start building "premium" from the inside out.

The 'SPI' finish standard for molds dictates the final texture of a plastic part, from matte to mirror-perfect.Vrai

The Society of the Plastics Industry (SPI) defines standards like A-1 for high-polish optical parts and C-3 for a standard matte finish, directly impacting the product's look and feel.

Tighter tolerances always result in a better product for the consumer.Faux

Excessively tight tolerances can increase manufacturing costs exponentially and may not provide a noticeable user benefit. Sometimes, a slightly larger, but consistent, gap is better for disassembly and cleaning.

How Do You Engineer Performance That Customers Can Actually Feel?

Your product's technical specs are impressive, but user reviews are mediocre because customers don't buy numbers. Translate your engineering specs3 into tangible, felt experiences they can understand.

Focus on the human outcome, not the engineering spec. Instead of decibels, market "bedroom quiet." Instead of ml/h, promise a "30-minute comfort window." This approach connects technical performance directly to the user's desired benefit, making the value proposition clear and compelling.

I remember a client who was obsessed with the airflow rate of his new air purifier. The cubic feet per minute (CFM) was off the charts. But the product was loud, even on the lowest setting. It failed because people couldn't sleep with it on. The spec was great, but the felt result was terrible. Premium brands understand this. They engineer for the human experience.

From the Lab to the Living Room

As a product designer, you are the bridge between the engineering lab and the customer's living room. Your job is to ensure the performance is not just measurable, but meaningful. For a humidifier, this means no "white dust" (a result of mineral deposits). For an air purifier, it means no annoying high-pitched whine from the fan motor. These are design and manufacturing challenges.

- For Quiet Operation: This involves fan blade design, the quality of the motor bearings, and how the motor is mounted to the chassis to dampen vibration. Every rib and vent you design in the housing can affect the acoustic profile.

- For Consistent Output: This is about the reliability of the core technology. For a humidifier, it could be the design of the ultrasonic nebulizer or the wicking filter to prevent mineral buildup that reduces performance over time.

| Technical Spec | User-Centric Language | Design Implication |

|---|---|---|

| Noise Level: 24 dB(A) | "Whisper-quiet for light sleepers" | Use of a brushless DC motor, acoustic insulation. |

| Humidity Output: 500 ml/h | "Fills a 500 sq ft room in 30 mins" | Efficient nebulizer/fan system, optimized airflow path. |

| Water Tank: 1.5 Gallons | "Up to 60 hours of runtime" | Balance between device footprint and user convenience. |

| Filter Pore Size: 0.3 microns | "Captures 99.97% of dust & allergens" | Specify HEPA-grade filter media, ensure tight seals. |

Your goal is to translate every engineering decision into a story about a better user experience. When you do that, the performance becomes something customers will happily pay more for.

A brushless DC motor is generally quieter and more efficient than a standard AC motor of the same size.Vrai

Brushless DC motors lack physical brushes, which reduces mechanical noise, friction, and wear, leading to quieter operation, better speed control, and a longer lifespan.

White dust from humidifiers is a sign that the device is broken.Faux

White dust is typically mineral residue from hard water that is dispersed into the air by ultrasonic humidifiers. It's a byproduct of the water source, not a device malfunction, though some designs manage it better than others.

Can User Experience Truly Be a Competitive Moat?

Your product is powerful but frustrating to use or clean, leading to bad reviews and high return rates. You must design for the entire ownership journey, not just the first use.

Yes, a seamless experience is a powerful moat. From a satisfying unboxing to tool-less, easy cleaning, great UX builds deep loyalty. Premium brands minimize friction at every touchpoint. This focus on the daily ritual, especially cleaning, is often the biggest differentiator and prevents costly returns.

I've seen the data from retailers: the number one reason humidifiers are returned is because they are a hassle to clean. The gunk builds up in hard-to-reach places, and people just give up. This is a failure of design, not technology. The best appliance makers design for cleaning4 first, then everything else. As a mold designer, you are at the center of this.

Designing for the Full Lifecycle

A premium experience is not a single moment; it's a collection of well-designed interactions over the life of the product. You have to think like the user. What happens on day one? Day seven? Day 365?

- Unboxing: Is it a frustrating mess of twist-ties and cheap plastic bags, or a guided, satisfying reveal?

- Daily Use: Is filling the tank a spill-free, one-handed operation? Is the control a single, intuitive dial or a confusing panel of buttons?

- Weekly Cleaning: Can every part that touches water be easily disassembled without tools? Are the surfaces smooth and the openings wide enough to get a hand or brush inside?

This is where your expertise in mold design is critical. Designing for "rinse-cleanable" parts means using large radii on all internal corners to prevent gunk from getting trapped. It means designing snap-fits that are robust enough for hundreds of cycles.

| Ownership Stage | Key Design Consideration | Customer Feeling |

|---|---|---|

| Unboxing | Molded pulp inserts, minimal plastic, clear first-step guide. | "This feels thoughtful and high-quality." |

| First Use | One-button start, clear icons, minimal setup. | "Wow, that was easy." |

| Daily Use | Large fill-hole, stable base, intuitive controls. | "This fits right into my routine." |

| Weekly Clean | Tool-less disassembly, dishwasher-safe parts, no sharp corners. | "Cleaning isn't a chore." |

| Long-Term | Easy-to-order filters, proactive service reminders. | "This company has my back." |

If your app adds friction to the setup without providing sustained, daily value, it's actually hurting the premium experience. Precision beats feature bloat every time.

Designing parts to be 'dishwasher safe' only requires using a plastic with a high melting point.Faux

It also requires designing the part to withstand harsh detergents, high-pressure water jets without flexing, and repeated heat cycles without warping. The part geometry is as important as the material choice.

Molded pulp packaging is often cheaper and more sustainable than expanded polystyrene (EPS) foam.Vrai

Molded pulp is made from recycled paper materials, is biodegradable, and can be custom-molded to protect products effectively, often at a lower cost than petroleum-based EPS.

How Can You Make Reliability and Safety a Visible Marketing Asset?

Customers are naturally anxious about product failures, leaks, and electrical safety. This hesitation can kill a sale before it even happens. You need to make your robust engineering visible.

Showcase your design decisions. Use cutaway renders on your product page to show over-specced seals, corrosion-resistant parts, and smart anti-scale designs. Treat safety compliance not as a boring requirement but as a badge of honor, summarizing test reports to build trust.

Reliability isn't an invisible feature; it's something you can and should design to be seen. When a customer is spending premium money, they are buying peace of mind. Your design can give them that. I've worked on projects where we deliberately made certain components look more robust than they technically needed to be. We weren't deceiving anyone; we were communicating the strength that was already there.

Show, Don't Just Tell

As a designer, you make hundreds of small decisions that add up to a reliable product. The choice of a specific screw, the thickness of a seal, the geometry of a water channel—these all matter. Don't hide this work.

- Visible Components: Use exploded diagrams and cutaway views in your marketing. Show the stainless-steel fasteners instead of cheap zinc ones. Highlight the thick, custom-molded silicone seal that prevents leaks. Point out the sealed bearings on the fan motor that will last for years.

- Compliance as Proof: Safety certifications like UL, ETL, and CE aren't just legal checkboxes; they are proof of quality. Don't just put the logo on the box. Create a small section on your website that explains what these tests mean in simple terms. "This ETL mark means our product has been independently tested for electrical safety, giving you peace of mind."

| Reliability Feature | Design/Mold Consideration | Customer Benefit (The "Why") |

|---|---|---|

| Over-molded Silicone Seal | Two-shot injection molding process. | "Guaranteed leak-proof design." |

| Anti-Scale Geometry | Smooth, sloped surfaces in the water path. | "Reduces mineral buildup for easy cleaning." |

| Sealed Bearing Fan Motor | Sourced component, but housing must fit. | "A quiet motor that's built to last." |

| UV-Stabilized Plastic | Use of specific additives in the polymer. | "Won't turn yellow in the sun." |

By making these engineering choices visible, you reduce customer anxiety and give them concrete reasons to trust your brand and your price point.

UL and ETL are competing government agencies that certify product safety.Faux

Both are Nationally Recognized Testing Laboratories (NRTLs) recognized by OSHA in the US. They are private companies that test to the same safety standards. ETL is a mark from Intertek, while UL is its own organization.

A two-shot injection molding process creates a permanent chemical bond between two different materials.Vrai

When compatible materials (like a rigid plastic and a thermoplastic elastomer) are used, the first shot is still hot when the second is injected, creating a melt bond that is far stronger than a simple press-fit or glued assembly.

Why Should You Think in Platforms, Not Just Products?

You launched one successful product, but now what? Competitors will quickly copy your idea, and your growth will stall. You need to turn your hero product into an ecosystem.

platform thinking5 creates long-term value and a strong defensive moat. By designing a shared core, you can efficiently launch variations (different sizes, finishes) and an ecosystem of accessories and consumables. This increases customer lifetime value and makes your brand a category leader.

The smartest companies I've worked with don't design a single product; they design a platform. This is a huge lesson from the appliance world. Think of a stand mixer. The core motor and gearing are the platform. From there, the company can launch dozens of attachments, bowls, and accessories. This is a brilliant strategy that we can apply to almost any wellness product.

The Manufacturing Advantage of Platforms

From a mold design and manufacturing perspective, this is incredibly efficient. You invest heavily in the complex, expensive molds for the core "chassis"—the internal mechanics, motor mounts, and fluid pathways. This is your platform.

- Shared Core: The most difficult engineering is done once. This core contains the main technology that makes your product great.

- Variable Exteriors: You can then create different SKUs by designing new, less complex molds for the external housing. This allows you to offer different sizes, colors, and finishes at a much lower incremental cost.

- Ecosystem of Consumables: The platform can be designed to work with a range of filters, cleaning solutions, or even aromatherapy pods. This creates a recurring revenue stream and locks the customer into your ecosystem.

| Platform Component | Mold/Manufacturing Strategy | SKU Examples |

|---|---|---|

| Core Power/Fluid Module | High investment, complex multi-cavity molds. | Shared across all products. |

| Small Housing/Tank | Simpler, lower-cost mold. | "Compact" model for bedrooms. |

| Large Housing/Tank | Larger, but still simple mold. | "Plus" model for living rooms. |

| Accessory Dock | Small, inexpensive mold. | Dock for aromatherapy pods. |

This approach lets you expand your product line quickly, respond to market trends, and build a brand that owns a category, not just a single spot on the shelf.

A multi-cavity mold produces multiple identical parts in a single injection cycle, reducing the cost per part.Vrai

While the initial mold is more expensive to build, the increased throughput and efficiency during mass production lead to a significantly lower unit cost for high-volume parts.

Using a platform strategy means all products in the line must look identical.Faux

The core internal components are shared, but the external housings can be completely different in shape, size, color, and material, allowing for a diverse product portfolio built on an efficient, common base.

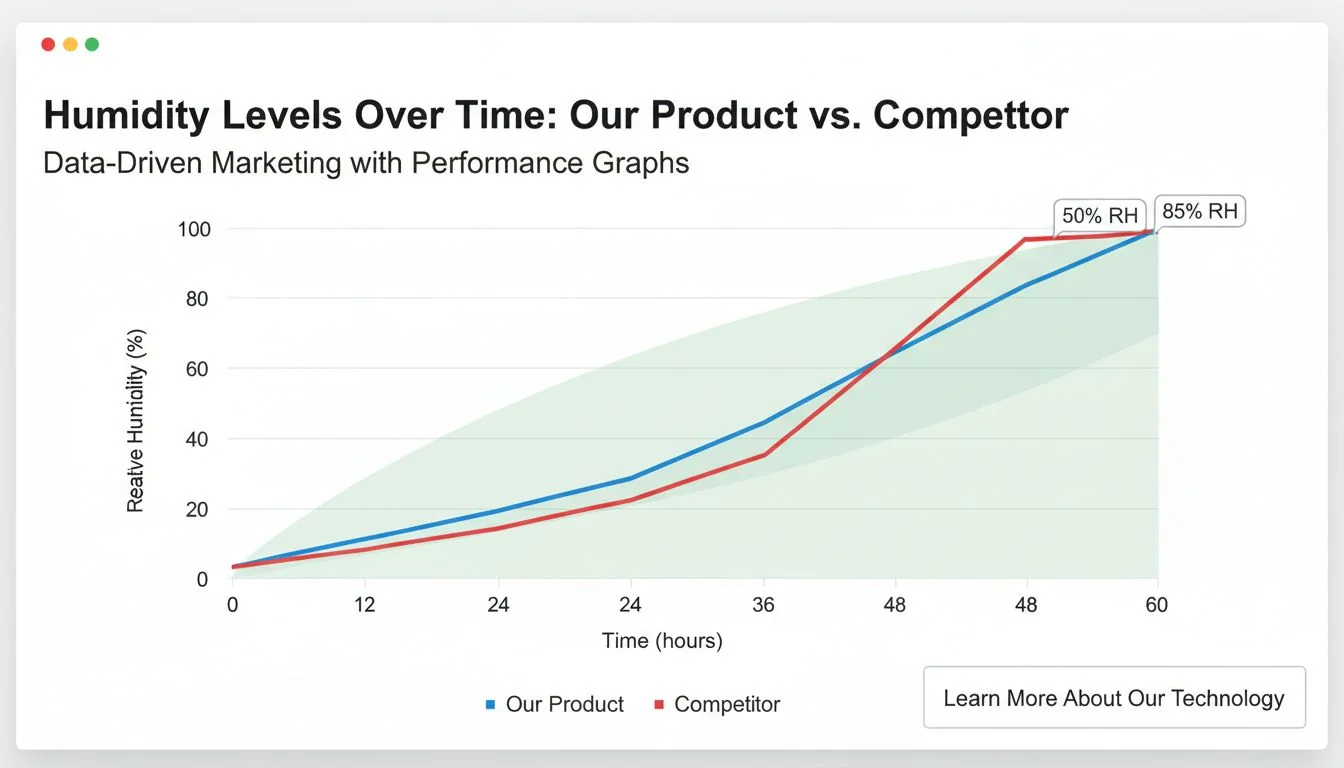

You've built a premium product, but customers still say it's too expensive because your marketing is all hype. You must prove your product's value with data and a clear narrative.

Ditch the vague slogans and provide concrete proof. Publish performance graphs, acoustic plots, and side-by-side comparisons. Tell the full lifecycle story, from unboxing to long-term care. Structure your pricing so that each tier offers a clear, tangible upgrade in value.

The final piece of the puzzle is how you talk about your product. Premium appliance brands don't just say "it's better." They show you the proof. They have the confidence that comes from excellent engineering and design, and they aren't afraid to share the data. As the designer, you should be thinking about what data to collect during development that can later be used as a powerful marketing tool.

Price with Integrity

Your pricing can't be arbitrary. Customers are smart; they can tell when a "premium" version is just a different color with a 50% markup. Your price architecture must be built on meaningful, tangible steps that you, the designer, have implemented. Each jump in price must earn its keep with a real, demonstrable improvement in features, performance, or materials. This builds trust and makes the customer feel smart for choosing the tier that's right for them.

| Price Tier | Key Feature Upgrade | Manufacturing/Design Justification |

|---|---|---|

| Good (Base) | Core humidification technology. | Standard motor, ABS plastic tank. |

| Better (Mid-Tier) | + Silent Mode + Stainless Steel Tank |

Brushless DC motor, deep-drawn steel tank. |

| Best (Top-Tier) | + Advanced Descaling + Sealed Bearing Fan |

Special part geometry, higher-spec sourced motor. |

When you present your product this way, you're not just selling a device. You're selling confidence. You're showing the customer all the thoughtful decisions that went into making a product that is genuinely better and worth the price. This is how you win in the premium market.

Acoustic plots, or spectrograms, can visually represent the noise profile of a product, showing not just volume but also pitch.Vrai

This data is far more descriptive than a single decibel number and can be used to identify and engineer out annoying high-pitched whines or low-frequency rumbles.

Time-to-target-RH' means the time it takes for a radio station to reach its target audience.Faux

In the context of humidifiers, 'RH' stands for Relative Humidity. 'Time-to-target-RH' is a performance metric measuring how quickly a humidifier can raise the humidity of a room to a desired level (e.g., 45%).

Conclusion

Building a premium wellness product isn't magic. It's intentional design, honest materials, and a deep respect for the user's entire journey. Apply these lessons to build lasting value.

References

-

Understanding material honesty can elevate your product's perceived value and customer trust. ↩

-

Tight tolerances can enhance product quality and customer satisfaction. ↩

-

Discover how to connect technical specifications with tangible user benefits. ↩

-

Effective cleaning design can significantly enhance user satisfaction and reduce returns. ↩

-

Understanding platform thinking can help you create a sustainable product ecosystem. ↩