You want to build a premium water purifier brand. But finding a factory that handles complex engineering, not just plastic assembly, is a nightmare. How do you filter the noise?

A high-end manufacturer must demonstrate mastery over three specific areas: advanced material integration1 (specifically stainless steel over plastic), thermal engineering capabilities (instant heating and cooling), and a comprehensive compliance portfolio (NSF/ETL). These factors separate true appliance engineers from simple assembly shops.

I have seen many designers get fooled by a shiny exterior. They look at the casing and think the product is good. But the real story happens inside the machine. Let’s look at what really matters.

Most water purifier factories in Asia can manufacture instant heating systems safely.Faux

Only a small percentage of factories have the thermal engineering capability to manage instant heat safely within a compact RO system.

Defining high-end specs creates a barrier to entry for low-quality competitors.Vrai

By requiring complex features like Stainless Steel and Instant Heat, you disqualify 90% of basic assembly factories.

Introduction: Why Must You Define "High-End" in a Sea of Plastic?

The market is flooded with cheap plastic filters. To stand out, you must redefine what "luxury" means in water purification.

High-end is not about a glossy plastic shell. It is about the convergence of medical-grade materials, precise thermal control, and reverse osmosis in one compact unit. This combination disqualifies 90% of standard factories immediately.

In my years in the mold industry, I have learned a key lesson about competition. You must set the bar impossibly high. This is a classic competitive strategy. If you look for a factory that just makes "water filters," you will find thousands of options in China and Vietnam. They all look the same. They all use the same cheap plastic molds. They compete only on price. You do not want to be in that race.

Instead, you must define "High-End" as a specific combination of features. You want a manufacturer that can do Stainless Steel AND Instant Heat AND Reverse Osmosis (RO). When you ask for this combination, you will see a change. The "plastic-only" factories will back away. They cannot do it. This effectively creates a "category of one" for your brand. You are no longer selling a commodity. You are selling a complex appliance. This strategy filters out the low-quality suppliers before you even look at a sample. It ensures you are talking to engineers, not just assemblers.

Plastic-only factories can easily switch to manufacturing stainless steel components.Faux

Stainless steel requires entirely different tooling, welding, and processing capabilities compared to plastic injection molding.

Combining RO filtration with heating elements requires advanced engineering.Vrai

This integration demands thermal management to prevent overheating and ensure consistent performance.

Criterion #1: Does the Manufacturer Have Material Mastery Beyond Plastic?

Plastic molds are standard. But does your manufacturer understand the hygiene requirements of internal water pathways?

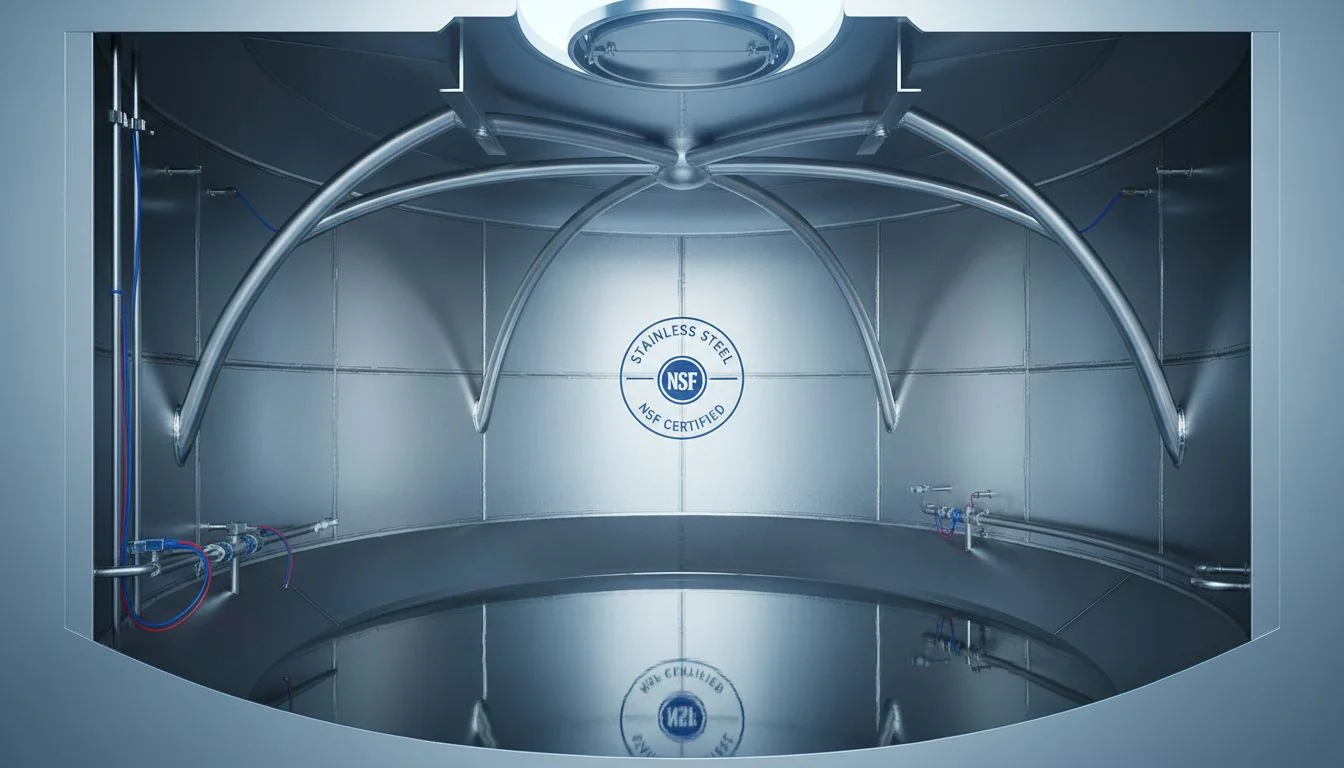

Look for a manufacturer that uses stainless steel for internal piping and tanks. Unlike plastic, steel prevents biofilm buildup and secondary pollution. This "internal hygiene2" is the true definition of luxury for health-conscious consumers.

As a designer, you know that the outer shell is just for show. The customer sees the outside, but they taste the inside. This is where the "Internal vs. External" quality argument comes into play. Many factories spend all their money on the external plastic mold to make it look pretty. But inside, they use cheap plastic tubes and tanks. Over time, plastic degrades. In a hot water environment, plastic can leach chemicals. It can also develop biofilm, which is a slimy layer of bacteria.

Real luxury is about internal hygiene. You need to look for a manufacturer that masters stainless steel pathways. Stainless steel is hard to work with. It requires precise welding and higher tolerances than plastic. But it is sterile. It does not degrade with heat. When you market your product, you can tell your customers that the water never touches plastic during the heating process. This appeals to brands that value substance over hype. It proves that the factory cares about the water quality, not just the production speed.

Stainless steel water pathways prevent secondary pollution better than plastic.Vrai

Stainless steel is non-porous and resistant to biofilm formation, unlike plastic which can degrade and harbor bacteria.

External aesthetics are the most important indicator of a water purifier's quality.Faux

Internal components determine water safety and taste; a good exterior can hide poor internal engineering.

Criterion #2: Can They Handle Complex System Integration (RO + Heat + Cold)?

Filtering water is simple. Boiling it instantly inside a compact machine without melting components is an engineering challenge.

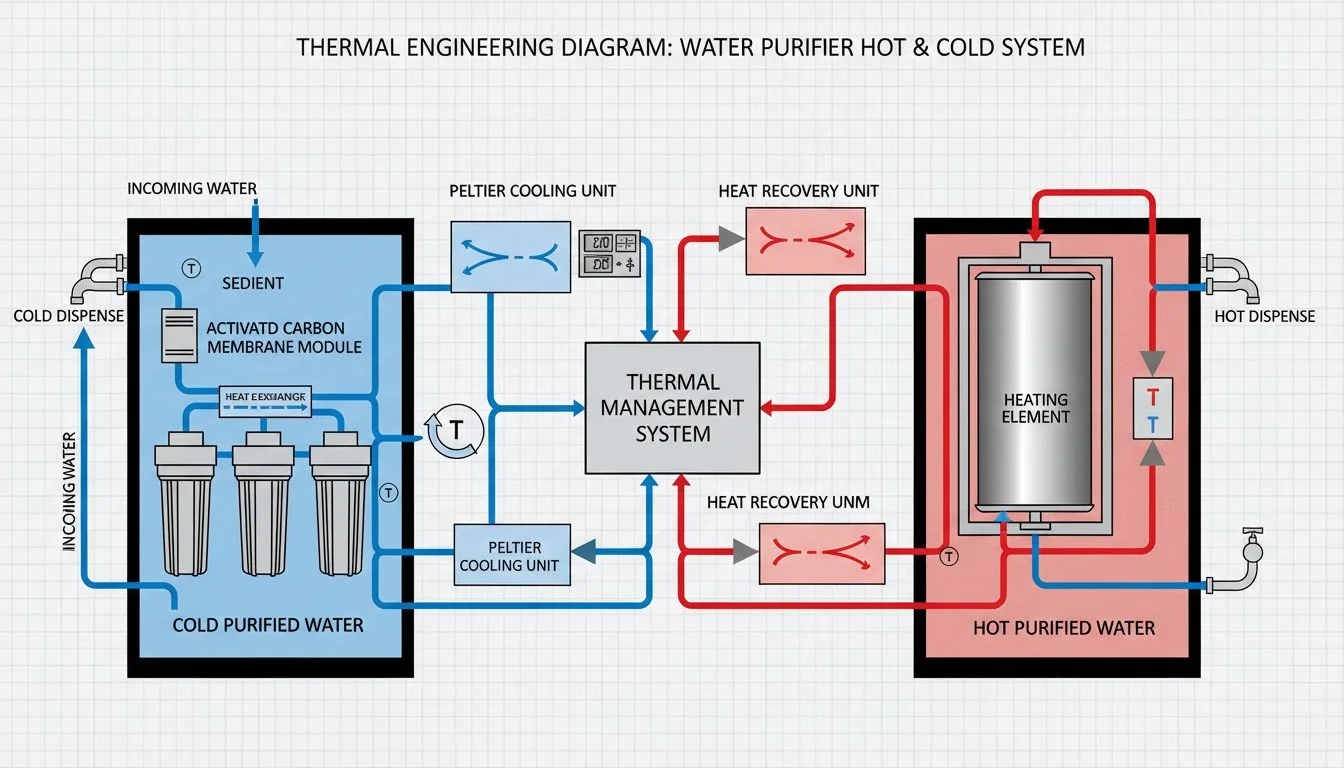

True "Tier 1" manufacturers possess thermal engineering capabilities3. They can integrate Reverse Osmosis filtration with instant heating and cooling systems. This separates low-level "gadget makers" from serious "appliance engineers."

We need to talk about "Thermal Engineering" as a differentiator. Many factories can buy a filter cartridge and put it in a box. That is easy. But very few can boil water instantly and safely inside a compact device. Even fewer can provide ice-cold water in that same device. This is the difference between a "gadget maker" and an "appliance engineer."

Think about the physics here. You have a Reverse Osmosis system, which involves high pressure and water. You have a heating element that reaches 100 degrees Celsius. You have a cooling compressor. You are putting all of these things into a very small box. If the design is bad, the heat will damage the electronics. Or the condensation from the cold tank will cause shorts. A high-end manufacturer understands thermodynamics. They know how to manage airflow and insulation. When you see a factory that successfully integrates Hot, Cold, and RO, you know they have a strong engineering team. This capability is a key indicator of quality.

Thermal engineering is a standard capability for all water purifier manufacturers.Faux

Most manufacturers lack the expertise to safely integrate instant heating and cooling within a compact RO unit.

Poor thermal design can lead to electronic failure in water purifiers.Vrai

Excessive heat or condensation from cooling systems can damage sensitive electronic components if not managed correctly.

Criterion #3: Do They Offer a "Compliance Shield" of Pre-Certified Solutions?

A product recall4 can destroy your brand overnight. Does your OEM partner offer protection against this risk?

View compliance certifications like NSF and ETL not just as rules, but as "brand insurance5." A high-end manufacturer provides a deep portfolio of pre-certified solutions, saving you time and protecting you from legal liability.

For high-end brands, a lawsuit or a product recall is fatal. It destroys trust. This is why you must look at compliance differently. Do not look at certifications like NSF or ETL as just "rules" you have to follow. You should frame them as "Brand Insurance." Obtaining these certifications on your own is expensive and takes a long time. It can take months or even years.

A top-tier manufacturer will have a deep portfolio of pre-certified products. They have already done the hard work. They have already paid the fees. When you work with them, you are buying that safety. You are buying peace of mind. Premium buyers are willing to pay extra for this. They want to know that the materials are safe and the electrical systems will not catch fire. If a factory tries to convince you that certifications are "not necessary" or "too expensive," run away. They are asking you to drive a car without insurance.

Compliance certifications act as insurance for a brand's reputation.Vrai

Certifications like NSF and ETL minimize the risk of recalls and lawsuits, protecting the brand's image.

It is faster and cheaper for a brand to get certifications independently than to use a pre-certified factory.Faux

Leveraging a factory's existing certifications saves significant time and capital compared to starting the process from scratch.

Criterion #4: Is It Real R&D or Just Assembly?

Is your partner inventing new technology, or just assembling parts bought from other suppliers?

You need a partner that acts as a "Tier 1 OEM6," similar to automotive suppliers like Bosch. They should provide a complete, engineered engine for your brand, not just assemble loose components.

Let’s use an automotive analogy here. In the car industry, there are "Tier 1" suppliers like Bosch. They do not just make screws. They build entire engine systems or braking systems. The car brand just puts the system in their car. You need to view your water purifier manufacturer the same way. Are they a "Tier 1 OEM"? Or are they just a "parts supplier"?

A parts supplier buys a pump from here, a filter from there, and a heater from somewhere else. They screw it together. If something goes wrong, they blame the parts. A Tier 1 OEM does real R&D. They design the system as a whole. They understand how the pump affects the flow rate through the heater. They understand the software logic. They provide the complete, engineered system that powers your brand. You want a partner like Hisoair, who acts as the engine of your business. You focus on the brand and the customer. They focus on the technology.

A Tier 1 OEM provides complete engineered systems, not just assembly.Vrai

Tier 1 suppliers take responsibility for the entire system's design and performance, similar to major automotive suppliers.

Assembling components from various suppliers guarantees the best system performance.Faux

Without holistic system design (R&D), mismatched components can lead to poor performance and reliability issues.

Conclusion

Your manufacturer is your brand's engine. Choose a partner with engineering depth7, thermal mastery, and compliance insurance. Do not settle for plastic assemblers; build with true appliance engineers.

References

-

Understanding advanced material integration is crucial for ensuring the quality and durability of water purifiers. ↩

-

Internal hygiene is vital for health-conscious consumers, ensuring that water quality is maintained throughout the purification process. ↩

-

Exploring thermal engineering capabilities helps identify manufacturers that can safely manage heating and cooling in compact systems. ↩

-

Learning about product recalls can help brands understand the importance of compliance and quality assurance in manufacturing. ↩

-

Exploring the concept of brand insurance highlights the importance of certifications in protecting a brand's reputation. ↩

-

Understanding the role of a Tier 1 OEM can help brands choose partners that provide comprehensive engineering solutions. ↩

-

Engineering depth ensures that manufacturers can handle complex designs and integrations, leading to better product performance. ↩