You have a vision for a new air purifier brand. But the biggest question looms: what will it cost? Without a number, your project is stuck before it even starts.

The factory cost to manufacture a private label air purifier can range from $30 for a basic personal unit to over $150 for a premium, high-CADR model with smart features. The final price depends entirely on your specific requirements and design choices.

That's a pretty big price range, I know. You're probably wondering what makes one air purifier cost $30 and another five times that amount. The truth is, the final price isn't a mystery. It's the result of a few key decisions you will make during the development process. Understanding these factors puts you in control of your budget. Let's walk through them together, so you can see exactly how your vision translates into a real-world cost.

The color of an air purifier's plastic housing is the biggest factor in its final cost.Faux

While custom colors can add a small cost, factors like CADR, motor type, and filtration technology have a much larger impact on the price.

The cost of tooling for a custom-designed air purifier is a one-time expense, separate from the per-unit manufacturing cost.Vrai

Tooling (creating the molds) is a significant upfront investment, but once paid, the per-unit cost is what you pay for each item produced.

What Are the 5 Key Factors That Determine Your Air Purifier's Cost?

Feeling overwhelmed by all the technical specifications? Choosing the wrong ones can inflate your budget or, worse, result in a product that doesn't perform well. Let's focus on the five factors that matter most.

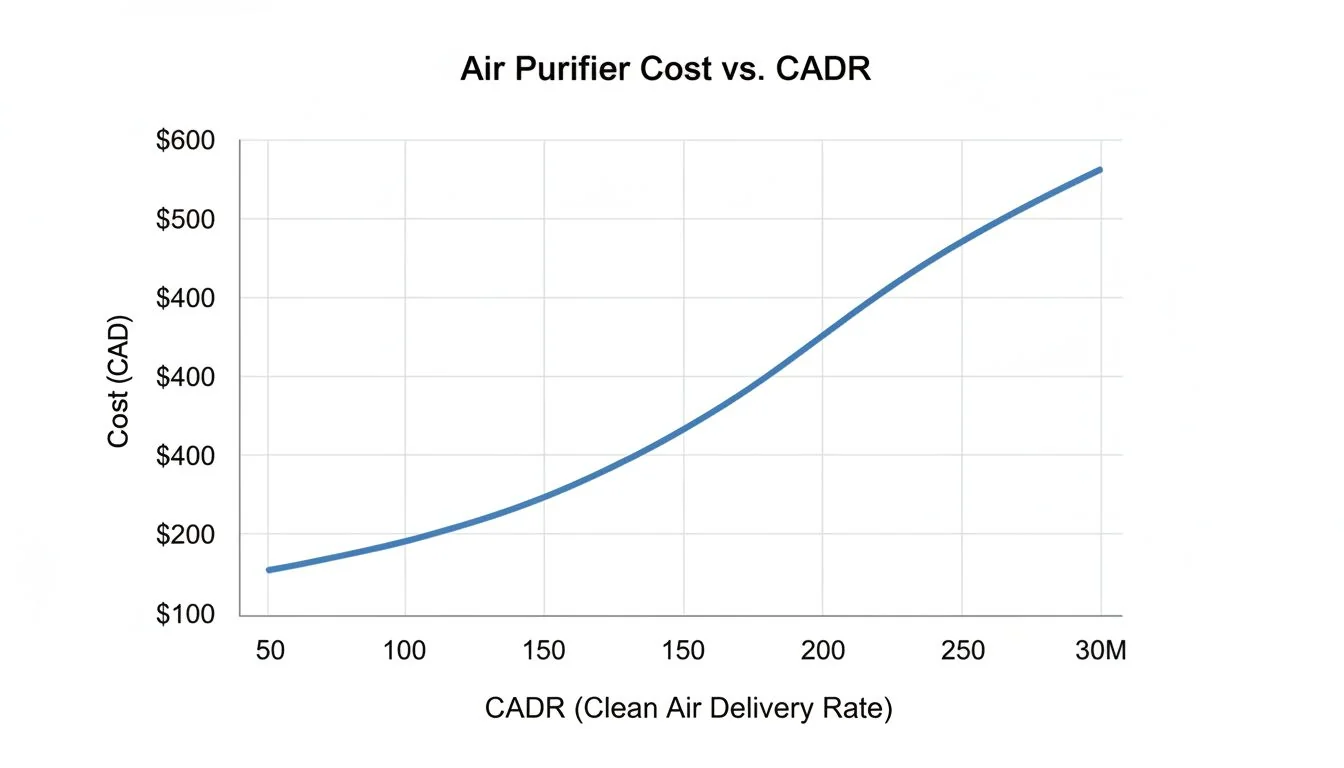

The five biggest cost drivers for an OEM air purifier manufacturer are its CADR (Clean Air Delivery Rate), Système de filtration1, materials and design, motor type, and any smart features or certifications you add. Each choice directly impacts your per-unit price.

Let's dive deeper into how each of these five elements affects your budget. When we work with new brands, these are the first things we discuss to align their product vision with their target cost. It's a balancing act, but understanding the trade-offs is the key to success. For example, a higher CADR is great, but it requires a more powerful motor and a larger filter, which both increase the price.

1. CADR (Clean Air Delivery Rate)

This is the most important performance metric and a major cost driver. It measures how quickly the purifier cleans a room. A higher CADR requires a larger, more powerful motor and fan, which costs more.

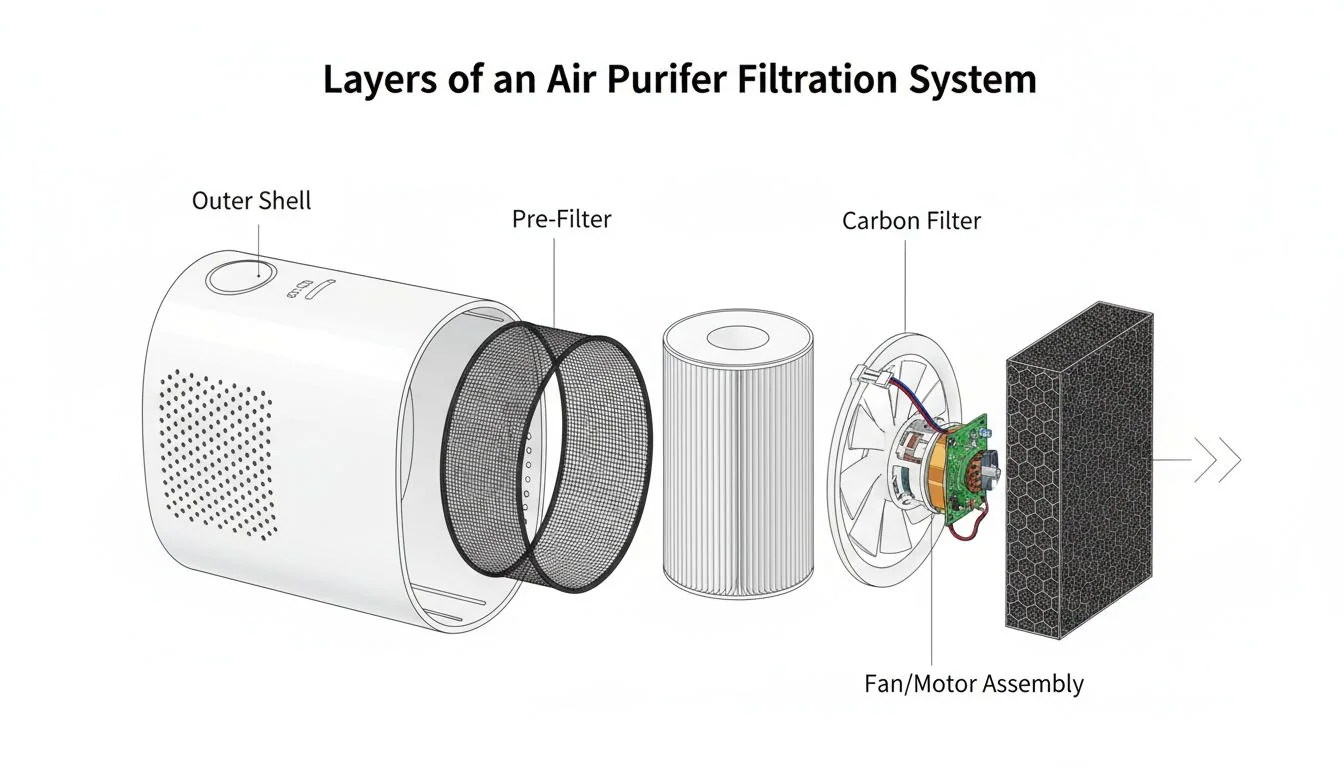

2. Filtration System

A simple 3-stage filter (Pre-filter, HEPA, Activated Carbon) is standard. Adding technologies like UV-C lamps, ionizers, or specialized carbon filters for VOCs will increase the air purifier manufacturing cost2.

3. Materials & Industrial Design

Do you want a standard matte white plastic finish, or a premium glossy finish with metallic accents? Custom shapes, complex designs, and premium materials like aluminum or wood grain finishes will increase both tooling and unit costs.

4. Motor Type

AC (Alternating Current) motors are cheaper and are often found in entry-level models. DC (Direct Current) motors are more expensive but are quieter, more energy-efficient, and allow for more precise fan speed control, making them the choice for mid-range and premium units.

5. Smart Features & Certifications

Want Wi-Fi connectivity and a custom app? That adds cost for hardware and software development. Certifications like Energy Star, CARB, or AHAM Verifide also add testing and compliance costs, but they build consumer trust.

All HEPA filters are the same, so you should always choose the cheapest option.Faux

There are different grades of HEPA filters. True HEPA (capturing 99.97% of 0.3-micron particles) is more effective and costs more than 'HEPA-type' filters.

A DC motor is more energy-efficient than an AC motor of a similar power rating.Vrai

DC motors are generally 60-80% more efficient than AC motors, which can be a key selling point and justify a higher retail price.

What Do Different Air Purifier Cost Scenarios Actually Look Like?

The factors are clear, but it can still be hard to picture a final cost. Abstract numbers don't help you build a business plan or budget for your specific vision. Let's look at three concrete examples.

An entry-level private label air purifier might cost $30-$50 per unit. A mid-range model for a standard room could be $60-$90. A premium, high-performance smart air purifier can easily exceed $100-$150, depending on the features and materials you choose.

Seeing these tiers helps you position your own brand. You don't have to compete on every level. In my experience, the most successful new brands pick one lane and excel in it. Are you targeting budget-conscious students with a small, affordable unit? Or are you aiming for health-conscious families who will pay more for high performance and smart features? Your target customer will determine which of these scenarios makes the most sense for you. Below is a table that breaks down what you can expect at each level.

| Fonctionnalité | Entry-Level | Mid-Range | Prime |

|---|---|---|---|

| Target Factory Cost | $30 - $50 | $60 - $90 | $100 - $150+ |

| CADR | Low (50-100 m³/h) | Medium (150-300 m³/h) | High (350+ m³/h) |

| Filtration | Basic 3-Stage (HEPA-type) | True HEPA, Activated Carbon | True HEPA, Advanced Carbon, UV-C |

| Motor | AC Motor | DC Motor | Brushless DC Motor |

| Conception | Standard Mold, Basic Plastic | Custom Accents, Better Finish | Fully Custom Design, Premium Materials |

| Caractéristiques | Manual Controls | Auto Mode, Air Quality Sensor | Wi-Fi/App Control, Voice Assistant |

| Best For | Small bedrooms, offices | Living rooms, master bedrooms | Large open spaces, health focus |

A 'private label air purifier' means you have to design the entire product from scratch.Faux

Private labeling often involves selecting an existing, factory-designed product and simply adding your own branding and packaging. This is different from OEM, which involves more customization.

The retail price of an air purifier is typically 3 to 5 times its factory manufacturing cost.Vrai

This markup, known as a multiplier, accounts for shipping, marketing, overhead, and profit margin. A $50 factory cost often translates to a $150-$250 retail price.

You've calculated your target unit cost and you feel ready to go. But wait. Unexpected costs like shipping, tariffs, and Custom Packaging3 can destroy your profit margins if you're not prepared for them.

Beyond the ex-factory price, you must budget for tooling (a one-time cost), custom packaging, international shipping, import duties, and final-mile logistics. These can add 20-40% or more to your total landed cost per unit, so they cannot be ignored.

When I first started in this business, I saw many promising projects fail because the founders only focused on the factory price. They were blindsided by these other expenses. A good manufacturing partner doesn't just give you a unit price; they help you see the full picture. This is a crucial part of figuring out how much to make an air purifier for. Let's break down these "hidden" costs so you're not caught by surprise.

1. Tooling & Mold Costs

If you want a unique design, you'll need to pay for custom injection molds. This is a one-time, upfront investment that can range from $15,000 to $50,000+ depending on the complexity of your design. Using a factory's existing "open mold" design eliminates this cost.

2. Custom Packaging

Your product's box is a critical marketing tool. The cost for custom-printed, full-color retail boxes with protective inserts is higher than a standard brown shipping box. Don't forget to budget for this per-unit expense.

3. Shipping & Freight

Moving thousands of units from a factory in Asia to a warehouse in North America or Europe is a major cost. Prices for ocean freight fluctuate, so it's important to get a current quote.

4. Tariffs & Duties

Every country has its own taxes on imported goods. These tariffs are calculated as a percentage of your product's value and can significantly impact your final landed cost. An experienced OEM air purifier manufacturer4 can help you classify your product correctly to ensure you pay the right amount.

You can avoid all import tariffs by shipping products one by one directly to customers.Faux

While this might avoid large commercial import duties, each individual package may still be subject to customs fees and taxes upon arrival, which can lead to a poor customer experience.

Using a factory's 'open mold' design is the fastest and most cost-effective way to launch a private label air purifier.Vrai

This approach eliminates the time and significant expense of creating custom tooling, allowing brands to get to market quickly with a proven design.

Ready to Get an Accurate Quote for Your Vision?

You now understand the key cost factors, but you still need a real number for your specific project. Generic estimates are helpful, but they won't work for your final business plan or investor pitch.

Getting a precise, detailed quote is the only way to know your true air purifier manufacturing cost. A reliable partner will work with you to balance features and budget, turning your idea into a real, manufacturable product.

This is the part of the process where everything starts to feel real. It's where your idea moves from a concept to a concrete plan. Here at Hisoair, we've guided hundreds of brands through this exact step. We don't just give you a price; we act as your consultant to help you make the right trade-offs. To get started, all you need to do is share your vision with us. Think about your target customer, the room size you're targeting (which helps determine CADR), any must-have features like an app or a special filter, and your ideal design. The more details you can provide, the more accurate your quote will be. We will analyze your requirements and provide a detailed cost breakdown, including the unit price, tooling options, and an estimate for other costs. This is a no-obligation process designed to give you the clarity you need to move forward with confidence.

Contact our team today to get a free, detailed quote and turn your vision into a reality.

You must have a finalized 3D CAD file before you can request a quote from a manufacturer.Faux

While a CAD file is needed for final production, you can get an accurate preliminary quote with a detailed description of your desired specs, features, and design ideas.

Providing a target retail price helps a manufacturer recommend features that fit your budget.Vrai

If you know you want to sell your product for $199, a good manufacturing partner can work backward to engineer a product with a target factory cost that makes your goal achievable.

Conclusion

Understanding manufacturing costs is the first step. Taking action by getting a custom quote is the next. Let's work together to build your successful air purifier brand.

References

-

Exploring different filtration systems can help you select the most effective technology for clean air. ↩

-

Understanding manufacturing costs is vital for setting a competitive price and ensuring profitability. ↩

-

Custom packaging can enhance your product's appeal and branding, making it worth the investment. ↩

-

Learning about OEM manufacturers can guide you in finding the right partner for your air purifier project. ↩