You have a brilliant idea for a new water purifier, but the cost of manufacturing scares you. Do you really need to build a factory just to launch a brand?

You do not need a factory. By adopting an asset-light strategy1 and using modular platforms, you can outsource the physical hardware while focusing entirely on your brand. This approach acts like AWS for hardware, allowing you to launch in months rather than years with much lower financial risk.

Many designers get stuck thinking they must control every single screw and plastic shell. I used to think this way when I started in the mold industry. We believe that owning the tools means owning the quality. But the market has changed. Today, speed and brand power matter more than owning heavy machinery. Let's look at how you can shift your focus and build a business, not just a product.

You must own a factory to ensure product quality.Faux

Modern manufacturing allows you to leverage established partners for high-quality production without owning the assets.

Outsourcing hardware production frees up capital for marketing.Vrai

Money saved on molds and machinery can be redirected to customer acquisition and brand building.

Is the "Hardware is Hard" Myth Holding You Back?

Everyone says "hardware is hard" because they think about the complexity of molds and supply chains. It stops many great ideas from ever reaching the market.

Hardware is only hard if you try to do everything yourself. The myth persists because people confuse product design with manufacturing infrastructure. You can bypass the "hard" parts by partnering with established backend providers who handle the heavy lifting, just like software companies do.

The AWS Analogy

This is the most powerful way to understand the modern manufacturing landscape. Think about how a software startup works today. If you want to build a new app, you do not buy land, build a building, and fill it with servers. That would be slow and expensive. Instead, you use Amazon Web Services (AWS). You rent the server space. You focus on the code and the user interface, while Amazon worries about the electricity and the cooling systems.

In the water appliance industry, companies like Hisoair2 act exactly like AWS. They provide the "Server." This includes the stainless steel tanks, the Reverse Osmosis (RO) technology, and the internal piping. Your job is to provide the "App." This is your brand, your external design, and your user experience. As a designer, you know that the internal mechanics of a water purifier are complex. Why spend years perfecting a pump system that already exists? When you treat hardware like software, the difficulty disappears. You plug into an existing infrastructure and turn your idea into a reality immediately.

| Fonctionnalité | Traditional Model | The "AWS" Model |

|---|---|---|

| Infrastructure | Build your own factory | Use existing platforms (Hisoair) |

| Focus | Managing supply chain | Designing user experience |

| Capital | Heavy upfront investment | Pay for what you use |

| Risk | High (Assets can fail) | Low (Shared resources) |

Software startups build their own server farms.Faux

Most software startups use cloud services like AWS to host their applications.

Hisoair provides the internal technology stack for water brands.Vrai

They supply the core hardware components, allowing brands to focus on design and marketing.

How Does the "Asset-Light" Strategy Work?

Spending your budget on steel molds leaves zero dollars for customer acquisition3. This is a common trap for engineering-led startups and designers who love tooling.

The asset-light strategy shifts capital allocation4. Instead of sinking money into fixed assets like tooling, you invest in variable costs like marketing and distribution. This financial agility allows you to scale faster and react to market trends without being weighed down by machinery.

Shift Capital Allocation

I have seen many talented people fail because they ran out of money before they made a single sale. They spent $100,000 on perfect molds and $0 on telling people the product exists. In the mold trade, I learned that a mold is a liability until it produces a part that is sold. If you are a founder or a lead designer, you need to think like a CFO.

Every dollar you spend on a custom mold is a dollar you are not spending on Instagram Ads, influencer partnerships, or retail slotting fees. This is a simple financial reality. By using a "Modular Platform," you free up that capital. You are not just saving money; you are moving it to where it actually generates revenue. When you pitch this to investors, you win. They do not want to fund a machine shop; they want to fund a brand that grows. You need to prove that you can sell the product, not just that you can make it. The asset-light model is the only way to do this efficiently in today's economy.

| Expense Category | Approche traditionnelle | Asset-Light Approach |

|---|---|---|

| Tooling & Molds | High ($50k - $200k) | Low / Zero |

| Marketing Budget | Low (Leftover funds) | High (Primary focus) |

| Inventory Risk | Haut | Managed by partner |

| Growth Speed | Slow | Fast |

Investors prefer funding machinery over marketing.Faux

Investors typically prefer capital efficient models where funds are used for growth and sales.

Molds are liabilities until they produce sold products.Vrai

Tooling costs are sunk costs that only offer a return when the final product is purchased.

Why Should You Leverage Modular Platforms Instead of Inventing the Wheel?

Designers often fear that using existing parts makes their product "generic." You worry your water purifier will look like everyone else's on the shelf.

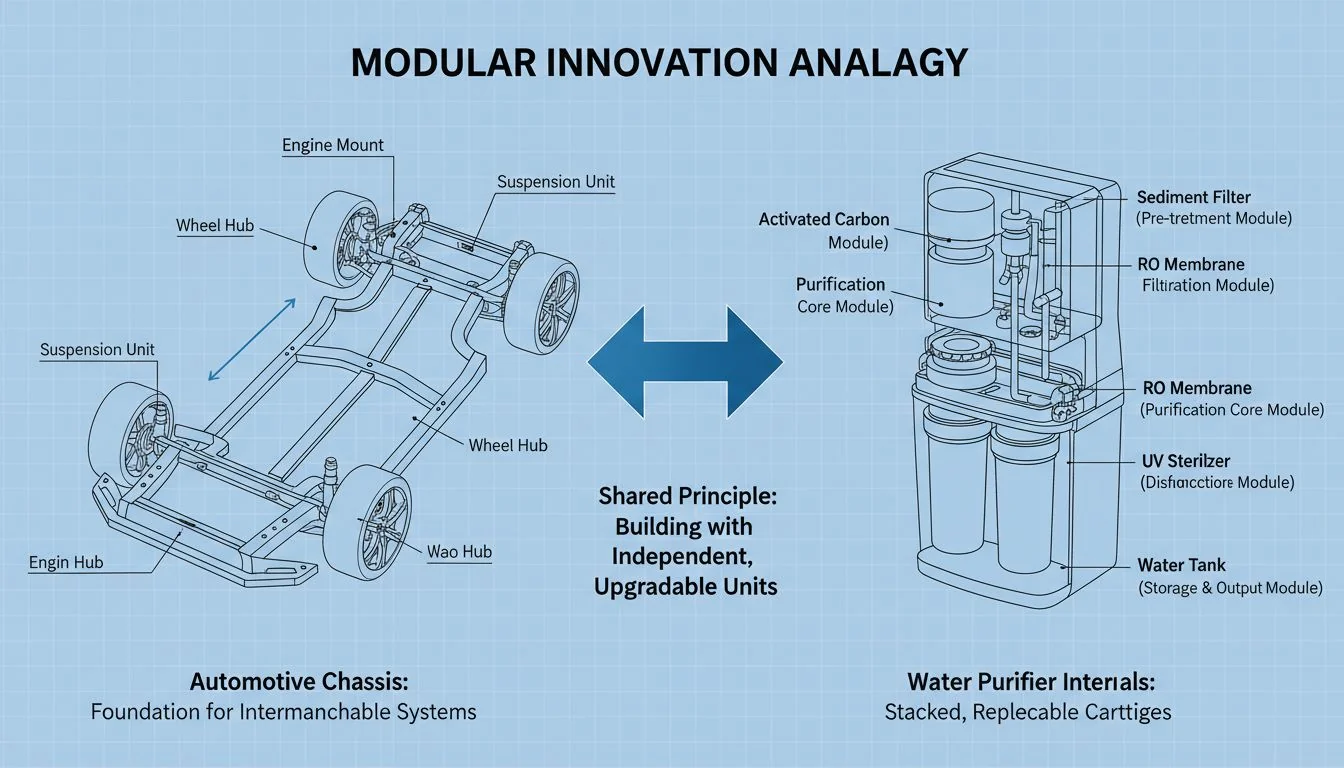

Utilisation modular platforms5 is not about being generic; it is about smart engineering. Think of it like a car chassis. We supply the engine and frame, and you design the body and interior. This allows for total brand uniqueness without the risk of developing core technology from scratch.

Modular Innovation

Let's talk about cars. When you buy a luxury car, you are often driving a vehicle that shares a chassis and engine with a much cheaper model from the same parent company. The "Platform" is the same. But the "Top Hat"—the body, the leather seats, the dashboard, the sound of the door closing—is completely unique. The customer does not care about the chassis; they care about the experience.

This is "Modular Innovation." In the water appliance world, you do not need to invent a new way to filter water. The technology for Reverse Osmosis is mature. If you try to reinvent it, you are just adding risk. Instead, use the platform provided by a partner like Hisoair. They give you the chassis and the engine. You design the body. You choose the colors, the interface, the handle feel, and the smart features. This allows you to be unique where it counts. You can create a product that looks and feels completely different from your competitors, even if the internal "engine" is the same. This is how you innovate without gambling your company's future on unproven mechanics.

| Composant | The Platform (Provider) | The Brand (You) |

|---|---|---|

| Core Tech | RO System, Pumps, Tanks | User Interface, Smart App |

| Structure | Internal Chassis | External Shell Design |

| Reliability | Tested & Certified | Brand Promise |

| Differentiation | Standardized Performance | Visual & Tactile Identity |

Using a platform means your product will look generic.Faux

You can design a unique exterior and user experience on top of a standard internal platform.

Car manufacturers share chassis across different models.Vrai

Major auto groups use shared platforms to reduce costs while maintaining distinct brand identities.

Can You Skip the Red Tape with a Compliance Cloud?

Getting water appliances certified takes months and costs a fortune. It is the most boring and dangerous part of the process for a new company.

You can skip the red tape by using pre-certified platforms. This is your "compliance cloud6." Just as cloud software handles security protocols, a manufacturing partner handles FDA and CE certifications. You inherit these approvals, saving you six to twelve months of bureaucratic headaches.

Speed-to-Market is the Killer App

In the wellness market, trends move fast. If you spot a trend today, you need to be on the shelf in six months. If you take two years to develop a product, the trend will be over by the time you launch. Traditional certification for water appliances involves rigorous testing for electrical safety and water quality. This can easily take a year.

Position your pre-certified platform as a "Time Machine." You are buying speed. When you use a platform that is already certified, you are not starting from zero. You are starting at the finish line of the technical race. You are selling speed. Launching in 6 months versus 24 months is often the difference between success and failure. You avoid the "Compliance Hell" where projects go to die. You focus on selling, while the platform provider ensures that the product is legal and safe to sell in your target markets.

| Activity | Custom Build Timeline | Pre-Certified Platform Timeline |

|---|---|---|

| R&D | 12 Months | 1 Month |

| Certification | 6-9 Months | 0 Months (Inherited) |

| Outillage | 3-6 Months | 1-2 Months (Modifications only) |

| Total Time | 2+ Years | ~6 Months |

Certification processes are quick and inexpensive.Faux

Certifications like FDA or CE can take many months and cost thousands of dollars.

Speed to market is critical in the wellness industry.Vrai

Consumer trends change rapidly, making long development cycles risky for new brands.

Do You Really Need Your Own R&D Team?

Hiring a full engineering team is expensive and slow. You might feel overwhelmed trying to manage mechanical, electrical, and hydraulic engineers alone.

You do not need a full in-house team. Treat your manufacturing partner as your "Virtual" Engineering Team. They provide R&D on demand. You act as the product architect, while they function as the "Intel Inside," handling the technical execution and reliability testing.

Hisoair as the "Back-End"

Think of your business structure. Do you want to manage a payroll of twenty engineers, or do you want to manage a brand? Your partner, in this case, Hisoair, becomes the invisible, reliable "Back-End" of your business. They are the "Intel Inside" for the next generation of wellness brands.

As a designer like Jacky, you are the architect. You set the vision. You define the user needs. You tell the Virtual Team what the product needs to do. Then, they figure out how to make the water flow correctly. They figure out how to keep the pump quiet. They figure out the electronics. You get the benefit of a massive R&D department without the overhead. This allows you to stay lean. You can run a multi-million dollar water brand with a tiny team because you are leveraging the intellectual property and human capital of your partner. This is the smartest way to build a hardware company today.

| Rôle | Your Responsibility | Virtual Team Responsibility |

|---|---|---|

| Vision | Define Product Concept | Execute Technical Design |

| Essais | User Acceptance Testing | Reliability & Stress Testing |

| Staffing | Lean Brand Team | Full Engineering Dept. |

| Coût | Fixed Salary | Included in Product Cost |

You need a large in-house team to launch a tech product.Faux

You can leverage the engineering teams of your manufacturing partners to handle technical development.

The 'Intel Inside' model applies to water appliances.Vrai

Component suppliers provide the critical technology that powers the final consumer product.

Conclusion

You are a brand company, not a factory. Leverage platforms to move fast. Save your money for selling, not molding. Be the architect, not the bricklayer.

References

-

Understanding the asset-light strategy can help you minimize costs and maximize brand focus. ↩

-

Discover how Hisoair can support your water appliance business with essential technology and infrastructure. ↩

-

Learn about innovative customer acquisition strategies to boost your brand's visibility and sales. ↩

-

Effective capital allocation strategies can significantly impact your startup's growth and sustainability. ↩

-

Exploring modular platforms can reveal innovative ways to enhance product uniqueness while reducing risk. ↩

-

Understanding compliance clouds can save you time and money in navigating regulatory requirements. ↩