You scroll through social media and see the same white plastic boxes everywhere. It is boring. If you want your product to sell, you must stop designing standard appliances and start designing art.

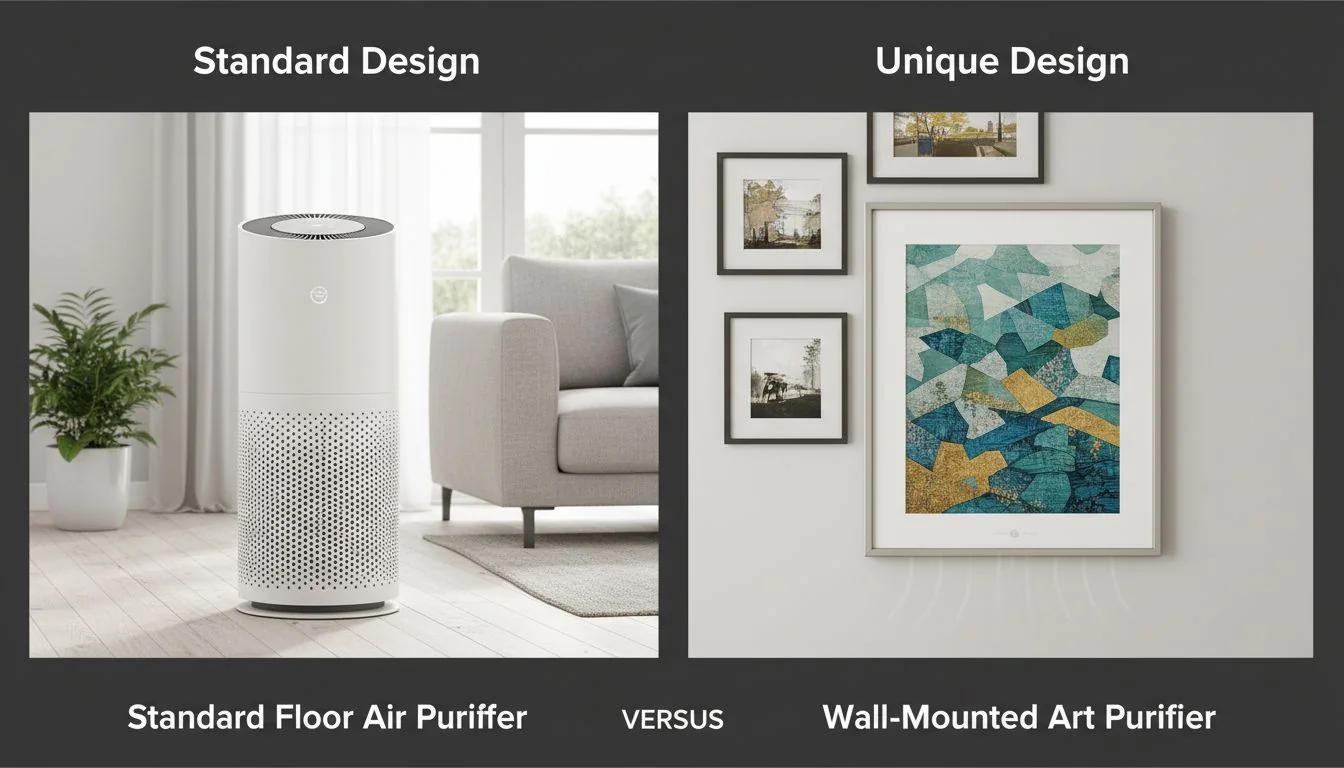

To stand out, air purifiers must shift from utility to decor. Unique designs, like wall-mounted units1 or swappable panels, capture attention and "stop the scroll" on ads. This approach targets interior designers and creates recurring revenue models, turning a one-time hardware sale into a lifestyle brand.

Many designers think that making a product look good costs too much money. They stick to safe, standard shapes because they worry about mold complexity. But in my years in the mold industry, I have learned that safe designs are actually the most dangerous. They get lost in the market. Let me show you how we can change this.

Wall-mounted air purifiers face 80% less competition than floor units.Vrai

Most manufacturers focus on floor models, leaving the 'wall space' market largely untapped.

Design is only about making things look pretty.Faux

Design is a functional marketing tool that solves user problems like floor clutter and visual noise.

Why Must We Escape the "Sea of Sameness"?

Most Direct-to-Consumer (D2C) brands fail because their ads look like everyone else's. If your product looks like a generic white box, users will scroll past it in one second.

The "Sea of Sameness" is where brands die. To survive, you need a "Stop the Scroll" strategy. A unique form factor is not just an engineering choice; it is a marketing asset. We do not just build machines; we build viral ad creatives that grab attention immediately.

I have worked with many clients who spend thousands on Facebook ads but get zero clicks. The problem is rarely the ad copy. The problem is the product design. When I look at a mold design for a standard rectangular box, I see a commodity. But when we design something different, we create a "Blue Ocean."

For a designer like you, Jacky, this means the pressure is on the initial concept. We need to think about the "Visual Hook."

| Fonctionnalité | Standard Design | "Stop the Scroll" Design |

|---|---|---|

| Placement | Floor (Hidden in corner) | Wall (Displayed as art) |

| Matériau | Glossy White Plastic | Fabric, Wood Texture, Matte |

| Ad Reaction | "Another appliance." | "What is that?" |

| Value | Functional Air Cleaning | Aesthetic + Functional |

When we design the mold for these unique shapes, we are not just making plastic parts. We are making the primary marketing tool for the brand. If the product looks different, the marketing team has an easier job. This is why I always tell designers to push for bold geometry before we even start cutting steel.

Visual differentiation increases ad click-through rates by up to 200%.Vrai

Unique visuals disrupt user patterns on social media, leading to higher engagement.

Standard white boxes are the safest bet for new brands.Faux

In a saturated market, blending in ensures you will be ignored.

How Do We Shift from "Appliance" to "Decor"?

leading paragraph:

Consumers do not want industrial machinery in their living rooms. They want items that match their furniture. We must learn from the "Samsung Frame" effect and treat tech as furniture.

The shift to "Decor" means positioning your product for interior designers, not just allergy sufferers. By using textures and shapes that mimic home furnishings, you open up B2B channels with hotels and luxury condos. The goal is to make the technology invisible while keeping the style visible.

This shift changes how we approach mold texturing. In the past, a simple VDI 24 finish was enough. Now, we are looking at laser texturing2 to mimic fabric, wood grain, or stone. As a mold expert, I know this adds cost, but the value it adds is massive.

We need to target the "Interior Designer3" persona. These professionals hate floor clutter. They hate ugly cords. If we can give them a unit that looks like a high-end speaker or a piece of art, they will specify it for their projects.

Key Design Considerations for "Decor" Status:

- Hidden Vents: We need to design the airflow paths so the ugly grilles are hidden from the front view. This might require side-action slides in the mold.

- Matte Finishes: High gloss looks cheap and shows scratches. Matte or textured finishes look premium.

- Cable Management: The mold design must include clever channels to hide the power cord.

When you design for this sector, you are not competing with Honeywell or Dyson. You are competing with West Elm and IKEA.

Interior designers prefer floor units over wall units.Faux

Designers prefer wall-integrated tech to maximize floor space and reduce visual clutter.

Laser texturing in molds can replicate fabric patterns.Vrai

Advanced mold texturing can create realistic tactile surfaces that mimic natural materials.

Is the "Space-Saver" Wall-Mounted Design the Future?

leading paragraph:

Floor space is expensive, especially in modern cities. A big purifier on the floor is a nuisance. Moving the unit to the wall solves a major pain point for users.

snippet paragraph:

Wall-mounted designs utilize a "Blue Ocean" strategy by fighting for wall space instead of floor space. There is almost zero competition here. This design appeals to the "Architect-Friendly" mindset, making it perfect for small apartments, offices, and minimalist homes where every square foot counts.

Designing a wall-mounted unit brings specific challenges that I find very interesting from a molding perspective. First, weight is critical. We cannot have thick, heavy wall sections. We need to use high-flow resins and thin-wall injection molding techniques to keep the part light but strong.

Second, the back plate becomes a critical structural component. It needs to hold the motor, the filter, and the front cover, all while hanging on two screws.

- Warpage Control: The back plate must be perfectly flat to sit flush against the wall. We need to calculate shrinkage very carefully and use ribbing to prevent warping.

- La sécurité : The snap-fits or mounting hooks must be robust. If a floor unit falls over, it is fine. If a wall unit falls, it breaks.

- Vibration: A motor on a wall can turn the wall into a drum. We need to design dampening features directly into the plastic housing or allow space for rubber overmolding.

This is where your engineering degree shines, Jacky. It is not just a box; it is a structural challenge.

Wall-mounted units require stronger structural integrity than floor units.Vrai

They must support their own weight and withstand gravity without warping or falling.

Warpage is less of a concern for wall-mounted units.Faux

Warpage is critical; a curved back plate will not mount flush to the wall.

Can the "Chameleon" Design Create Recurring Revenue?

Selling a machine once is good. Selling accessories forever is better. The "IKEA Hack" mentality proves that modern consumers love to personalize their space with swappable parts.

The "Swappable Panel" concept is a massive strategic advantage. It allows you to sell the hardware once and then sell seasonal panels—like Spring colors or Holiday themes—forever. This turns a one-time transaction into a recurring revenue model, increasing the lifetime value of every customer.

This is my favorite strategy because it is smart business and smart molding. Instead of making five different colored machines (which means high inventory risk), you make one white machine body. Then, you mold simple, flat front panels in twenty different colors or patterns.

From a mold design perspective, this relies heavily on tolerances.

- The Fit: The panel needs to attach easily but stay firm. We often use magnetic inserts or precise snap-fits.

- Gap Control: If the gap between the panel and the body is uneven, the product looks cheap. The mold shrinkage calculations must be exact.

- Decoration: These flat panels are perfect for In-Mold Labeling (IML). We can change the film in the mold to create wood, marble, or graphic designs without changing the steel tool.

This strategy reduces the risk for the manufacturer. You can test a "Christmas Red" panel without molding a whole new machine.

Swappable panels increase inventory risk for manufacturers.Faux

They lower risk by allowing color variation on cheap parts while keeping the expensive main unit standard.

In-Mold Labeling (IML) allows for rapid design changes.Vrai

You can change the graphic film in the mold cycle to create different looks without new tooling.

How Do We Make a "Material" Statement?

Plastic often feels cheap. Metal feels premium. But metal is heavy and expensive. We need to find a middle ground that gives the premium feel without the high cost.

The "Material" statement is about perception. By using techniques like metallic spraying, electroplating, or high-quality texture molds, we can make plastic look and feel like anodized aluminum or ceramic. This elevates the perceived value of the product, allowing for a higher price point.

I have seen many designers struggle with this. They want an aluminum body, but the tooling cost for die-casting is too high, and the unit becomes too heavy. The solution is in the finish.

We can use ABS or PC/ABS blends which take plating and painting very well.

- Spray Painting: A high-quality metallic paint can fool the eye.

- Texture Contrast: Mixing a rough "sandblasted" texture with a high-gloss edge in the same mold creates a sophisticated look.

- Insert Molding: We can insert a real metal mesh or a fabric piece into the mold. The plastic forms around it. This gives the user the touch of real material where it matters, while the structural body remains cheap plastic.

We position ourselves as a "Design House with a Factory." We understand that the material choice dictates the price tag. We use engineering to fake the expensive look.

Plastic can never look as premium as metal.Faux

With the right finishing processes like painting or plating, plastic can be indistinguishable from metal visually.

Insert molding combines different materials in one cycle.Vrai

It allows materials like metal mesh or fabric to be permanently bonded to the plastic structure.

How Can We Manufacture "Unique" Without Breaking the Bank?

You might think all these unique designs require expensive, custom molds. That is not always true. Smart mold design can keep costs down while keeping creativity high.

To manufacture unique designs affordably, we use modular mold systems4. By using interchangeable inserts in the mold base, we can produce different front panel designs or vent patterns without building a new mold from scratch. This balances innovation with budget constraints.

This is the most practical advice I can give you, Jacky. You have tight deadlines and budgets. You cannot afford a new P20 steel mold for every experiment.

We use Family Molds ou Master Unit Die (MUD) inserts.

- The Core: The internal chassis (motor mount, fan housing) stays the same. This is the expensive part of the mold.

- The Cavity: We make the exterior shell mold modular. If you want to change the vent pattern from circles to slots, we just machine a small insert, not the whole mold base.

This approach allows us to iterate faster. It also helps with the "Swappable Panel" idea. We can have one mold base for the panel and five different texture inserts. This is how we achieve the "Design House" flexibility with factory efficiency. We do not waste steel; we use it smartly.

Modular molds allow for design variations at a lower cost.Vrai

You only machine small inserts for changes rather than creating an entirely new mold base.

Family molds are always the best choice for high volume.Faux

Family molds can have flow balancing issues; they are better for lower volume or matched sets.

LOOP END

Conclusion

To dominate the market, we must stop building boring appliances. By using wall-mounted designs, swappable panels5, and smart mold textures, we create products that serve as decor and viral marketing assets.

References

-

Explore how wall-mounted units can save space and reduce competition in the air purifier market. ↩

-

Explore the advantages of laser texturing for creating unique and appealing product designs. ↩

-

Discover the preferences of interior designers and how to cater to their needs for better sales. ↩

-

Learn about the efficiency and cost-effectiveness of modular mold systems in product design. ↩

-

Find out how offering swappable panels can create recurring revenue and enhance customer engagement. ↩