We often look at a spec sheet and stop at the "micron rating." But if you are designing for real safety, that number is misleading. We need to look deeper.

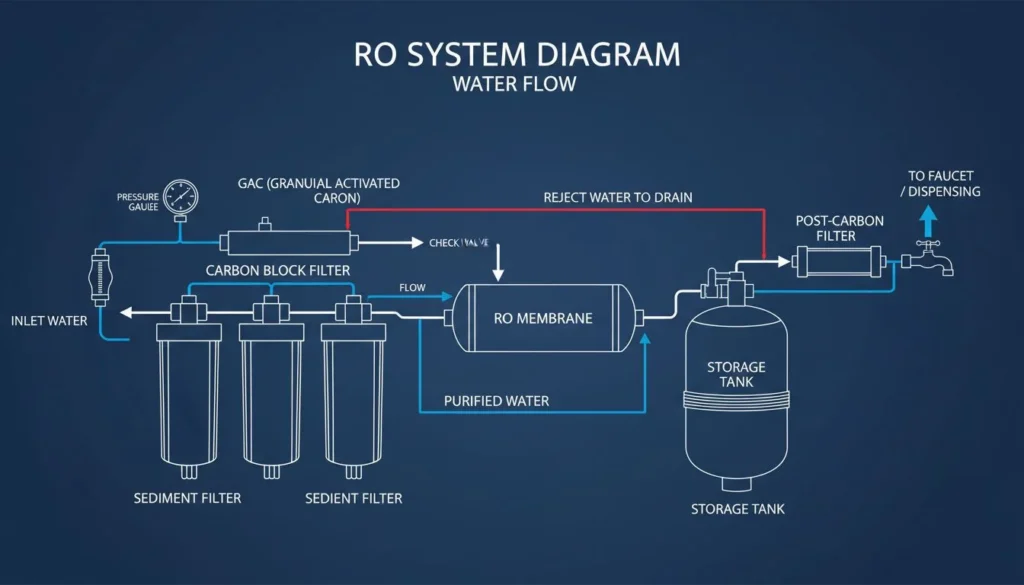

Filter safety depends on "Contact Time1" and structural integrity, not just pore size. Larger filters allow water to interact with carbon longer, removing chemicals like chlorine. Solid structures prevent "channeling," ensuring water doesn't bypass filtration media. This combination ensures both chemical adsorption and physical filtration.

Many designers think a smaller footprint is always better. However, when we deal with fluid dynamics and chemical reactions, size and structure are not just aesthetic choices. They are functional necessities. Let's look at the engineering behind this.

Micron rating is the only metric that matters for water safety.False

Micron rating only measures physical particle removal, not chemical adsorption capabilities.

Contact time is essential for removing dissolved chemicals.True

Chemicals like chlorine and lead require a specific duration of contact with carbon to be effectively adsorbed.

Introduction: Why "Micron Rating" Isn't the Whole Story?

I used to think that if a filter stopped a 0.5-micron particle, the water was clean. I was wrong. Physical barriers are only half the battle.

Micron ratings only measure physical exclusion. They stop dirt, rust, and cysts. However, they cannot stop dissolved chemicals if the water flows too fast. True safety requires considering the chemical interaction, which relies heavily on the filter's physical volume and internal design, not just the size of the holes.

In my early days at the mold factory, we obsessed over tolerances. If the pin fit the hole, the job was done. But in water filtration, "fitting" isn't enough. We have to think about the difference between physical screening and Chemical Adsorption2. A micron rating is just a physical sieve. It works like a net catching fish. If the fish is bigger than the net, it gets caught. This handles sediments and bacteria.

However, dangerous contaminants like Chlorine, Lead, and VOCs (Volatile Organic Compounds) are dissolved. They are smaller than water molecules. You cannot catch them with a net. You need a chemical reaction. This reaction happens on the surface of the activated carbon. If you force water through a thin, small filter at high pressure, the water shoots past the carbon before the reaction happens. It is like trying to shake hands with someone while running past them. You need to stop and engage. This is why relying solely on micron ratings is a design flaw. We must educate our clients that a tight filter might stop dirt, but it might still let poison through if the structure doesn't allow for proper interaction.

Physical vs. Chemical Filtration

| Feature | Micron Rating (Physical) | Adsorption (Chemical) |

|---|---|---|

| Mechanism | Mechanical Barrier | Chemical Bonding |

| Target | Sand, Rust, Cysts | Chlorine, Lead, Taste |

| Dependency | Pore Size | Contact Time & Surface Area3 |

| Risk | Clogging | Saturation / Pass-through |

A 0.5-micron filter automatically removes chlorine.False

Chlorine removal depends on carbon adsorption and contact time, not just the pore size.

Dissolved contaminants are smaller than water molecules.True

Chemicals like lead and VOCs are dissolved in water and cannot be mechanically filtered by standard micron pores.

The Concept of "Contact Time" (CT): Why Size Matters?

Clients love compact designs. They want everything to fit in a tiny box. But in filtration, shrinking the volume kills the performance.

Contact Time (CT) is the duration water touches the carbon. Short CT stops dirt but misses lead or chlorine. Larger filters provide the necessary residence time for chemical bonds to form, ensuring the water is actually safe, not just clear. This is why "Big Body" filters perform better.

Let's talk about the engineering constraint of time. In our industry, we usually try to reduce cycle times. But here, we need to increase the cycle time of the water inside the cartridge. This is the concept of Contact Time (CT). The formula is simple: Volume divided by Flow Rate4 equals Contact Time. If you have a small filter and a high flow rate, your CT is near zero.

I often explain this to B2B clients using the "Big Body" concept found in high-end filters like those from Hisoair. A small, cheap filter might look sleek, but it fails the chemistry test. To remove heavy metals like Lead, the water needs to "sit" with the binder and carbon. It needs residence time. When we design the housing for these filters, we aren't just making a container; we are defining the reaction chamber. A larger vessel allows the water to slow down relative to the media surface area, even if the output flow is fast. It is a buffer zone. If you cut the size in half to save plastic or space, you are effectively removing the chemical safety guard.

The Impact of Filter Volume

| Filter Size | Contact Time | Chemical Removal5 | Suitability |

|---|---|---|---|

| Small / Slim | Low (< 1 sec) | Poor (Physical only) | Basic Sediment |

| Standard | Medium | Moderate | Taste & Odor |

| Big Body | High (> 3 sec) | Excellent (Lead/VOCs) | Safety Critical |

Reducing filter size improves chemical removal efficiency.False

Reducing size reduces contact time, which lowers the efficiency of chemical removal.

Contact Time is calculated by Volume divided by Flow Rate.True

This physics principle dictates how long water remains in the reaction zone.

Have you ever seen water run through a crack in the pavement? It ignores the rest of the road. The same thing happens inside cheap filters.

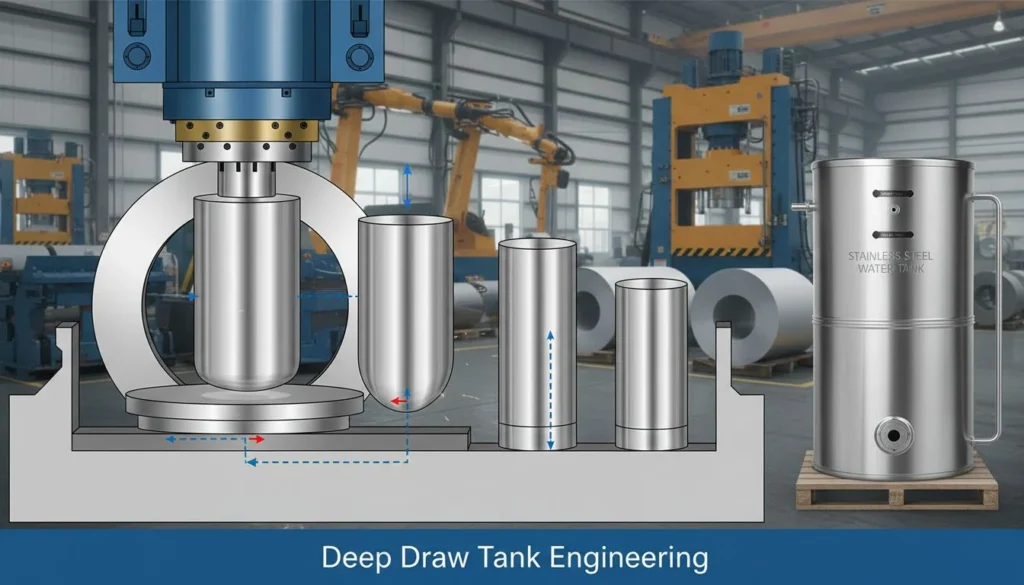

Channeling6 occurs when water finds the path of least resistance, bypassing the filter media entirely. This happens in loose granular filters. Sintered carbon blocks, which are molded into a solid structure, force water through the media, preventing this "cheating." This proves the value of superior manufacturing.

This is where our knowledge of molding becomes critical. In the market, you will see two types of carbon filters: Granular Activated Carbon (GAC) and Sintered Carbon Blocks7. GAC is just loose powder poured into a tube. It is cheap. But water is lazy. It follows the path of least resistance. Over time, the flowing water pushes the loose granules aside, creating a "tunnel" or a channel. Once this channel forms, 90% of the water flows through that empty gap. It doesn't get filtered at all. It is like a crack in a dam.

High-quality manufacturing, like the process used for Hisoair's Sintered Carbon Blocks, solves this. They mix the carbon with a polymer binder and heat it inside a mold. This sinters the material into a solid, rigid block. The structure is locked. The water cannot push the media aside. It is forced to travel through the complex maze of pores. As a mold designer, you know that structural integrity is everything. A solid block guarantees that every drop of water is treated. It prevents the water from "cheating."

Structure Comparison

| Feature | Loose Granular (GAC) | Sintered Carbon Block |

|---|---|---|

| Structure | Loose particles | Solid molded block |

| Water Path | Random / Channeling | Uniform / Forced |

| Risk Factor | High (Bypass) | Low (Consistent) |

| Manufacturing | Simple Filling | Molding & Sintering |

Loose granular filters are prone to channeling.True

Water pressure can displace loose granules, creating open paths that bypass filtration.

Sintering creates a solid structure that prevents water bypass.True

The heat and pressure bind the carbon into a rigid block, forcing water through the pores.

Longevity Math: Surface Area vs. Clogging?

We all want to save money. But buying a cheap mold usually costs more in repairs later. The same logic applies to filter maintenance.

A small filter clogs quickly due to limited surface area, requiring frequent changes. A larger filter offers more surface area, extending the maintenance cycle to a year. This reduces the Total Cost of Ownership8 (TCO) and improves the user experience significantly.

Let's look at the "Total Cost of Ownership" (TCO). This is a concept I use constantly when selling high-quality molds. A cheap mold breaks in 50,000 shots. A good mold lasts 1 million. In filtration, a small filter might cost $10. But because it has very little surface area, it gets clogged with sediment in 3 months. That is $40 a year, plus the hassle of changing it four times.

A larger, well-engineered filter might cost $30 upfront. But because it has a massive surface area, the sediment load is distributed. It doesn't choke. It can last a full year. The annual cost is $30. The client saves money, and more importantly, they save time. Consumers hate changing filters. It is messy and annoying. By designing for a "1-Year Maintenance Cycle," we are selling convenience. We are selling a "set it and forget it" solution. This is a massive branding advantage for your client. It turns a commodity product into a premium experience.

Cost & Convenience Analysis

| Metric | Small Filter | Large Engineered Filter |

|---|---|---|

| Unit Cost | $10 | $30 |

| Lifespan | 3 Months | 12 Months |

| Annual Cost | $40 | $30 |

| User Action | 4 times/year | 1 time/year |

| Value | Low | High |

Generate Claims

Small filters generally have a lower Total Cost of Ownership.False

Frequent replacement costs often make small filters more expensive annually than larger, long-lasting ones.

Larger surface area distributes sediment load effectively.True

More surface area prevents rapid clogging, extending the operational life of the filter.

The "Composite" Trend: Good Idea or Bad Engineering?

People hate waiting for water. They want the "faucet effect," not a trickle. But how do we get high flow without losing safety?

Composite Filters9 combine different media densities to balance flow and filtration. Poor engineering leads to pressure drops. Advanced structural engineering optimizes media packing to allow "Instant Fill" flow rates while maintaining the necessary contact time for safety. This is "Flow Rate" as a luxury feature.

In the premium market, flow rate is a luxury feature. Nobody wants to stand there for two minutes to fill a glass of water. But usually, if you want high flow, you have to sacrifice filtration quality (make the holes bigger). Or, if you want high quality, you sacrifice flow (make the holes smaller). This is the trade-off.

However, we can solve this with structural engineering. This is where "Composite" designs come in. Instead of a single block of uniform density, advanced manufacturers use a gradient structure. The outer layer is less dense to catch big dirt without slowing the water down. The inner layer is dense to catch the chemicals. It is like designing a runner system in a mold—you manage the pressure drop at each stage. By engineering the density and the path of the water, we can achieve "Instant Fill" speeds. We are not just pouring carbon in a tube; we are engineering the fluid dynamics. This justifies a higher manufacturing cost because it delivers a superior user experience.

Flow Rate Engineering

| Feature | Standard Filter | Engineered Composite |

|---|---|---|

| Flow Experience | "Trickle" | "Faucet Effect" |

| Pressure Drop | High | Optimized |

| Structure | Uniform Density | Gradient Density |

| User Wait Time | Long | Instant |

High flow rate always means poor filtration.False

With gradient density engineering, high flow can be achieved without sacrificing chemical removal.

Gradient structures manage pressure drop better than uniform structures.True

Layering densities allows for efficient sediment loading and smoother water flow.

Conclusion

Size and structure dictate performance. Don't just look at microns; engineer for contact time and structural integrity. This ensures safety, lowers long-term costs, and delivers the high flow rates users demand.

References

-

Understanding Contact Time is crucial for effective chemical removal in water filtration systems. ↩

-

Explore the process of chemical adsorption to learn how contaminants are effectively removed from water. ↩

-

Learn how surface area affects filter lifespan and efficiency in removing contaminants. ↩

-

Explore how flow rate impacts filtration performance and user experience in water systems. ↩

-

Understanding the mechanisms of chemical removal is essential for effective water filtration. ↩

-

Learn about channeling and its impact on filtration efficiency, and discover solutions to avoid it. ↩

-

Discover why Sintered Carbon Blocks are superior to granular filters in ensuring effective water treatment. ↩

-

Understanding TCO helps consumers make informed decisions about filter investments and maintenance. ↩

-

Discover the advantages of composite filters in balancing flow and filtration effectiveness. ↩