"Just change it every six months." This common advice for air purifier filter replacement sounds simple, yet it's often vague, wasteful, or even unsafe. In an era where indoor air quality is a growing concern, the demand for effective air purification is higher than ever. However, many users remain confused about filter replacement: should they strictly follow a calendar schedule, or wait for the device to signal a change? Ill-timed replacements not only incur unnecessary costs but can also compromise purification efficiency.

This article aims to demystify filter life by explaining the science of dust loading, the benefits of sensor-based replacement, and why High-Dust-Holding-Capacity (HDHC) filters can significantly slash both downtime and total cost of ownership. We will fundamentally shift your perspective on air purifier maintenance, guiding you towards smarter, more economical, and highly efficient air purification.

Dust Load, Not Calendar Days, Sets the Clock

The actual lifespan of an air purifier filter is not dictated by the calendar but by the amount of dust it accumulates. The fundamental equation is straightforward:

Service Life ≈ Dust-Holding Capacity ÷ Dust Inflow Rate

This formula reveals a crucial truth: a filter's life directly depends on how much dust it can capture and the rate at which dust enters the environment.

Consider the real-world contrast: an air purifier operating during a heavy-smog winter in will experience an extremely high dust inflow rate, significantly shortening its filter life. Conversely, the same air purifier used in the clean Hawaiian highlands, with a very low dust inflow rate, could see its filter last many times longer.

This means that simply relying on a manufacturer's suggested "six-month" or "one-year" replacement interval is insufficient. A responsible maintenance strategy must account for actual air quality conditions and usage intensity.

Different Filter Types, Different Failure Modes

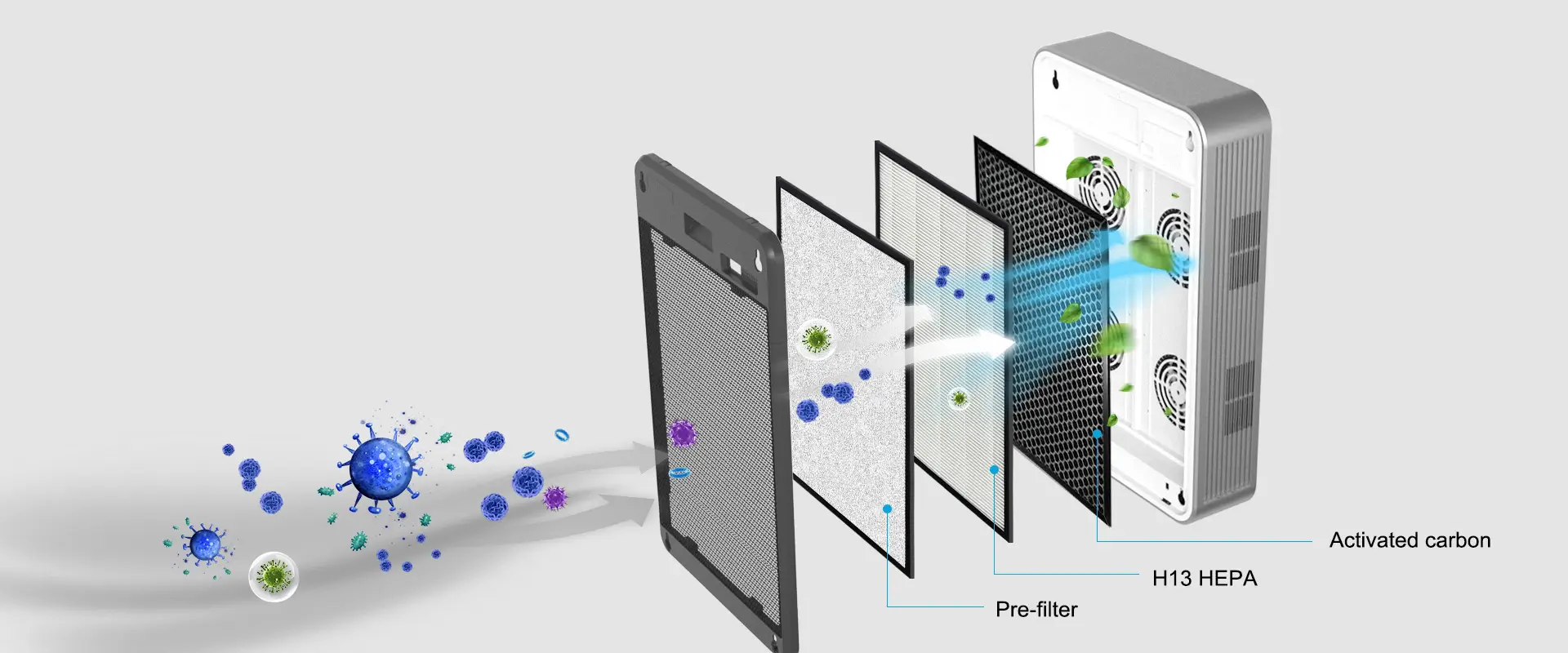

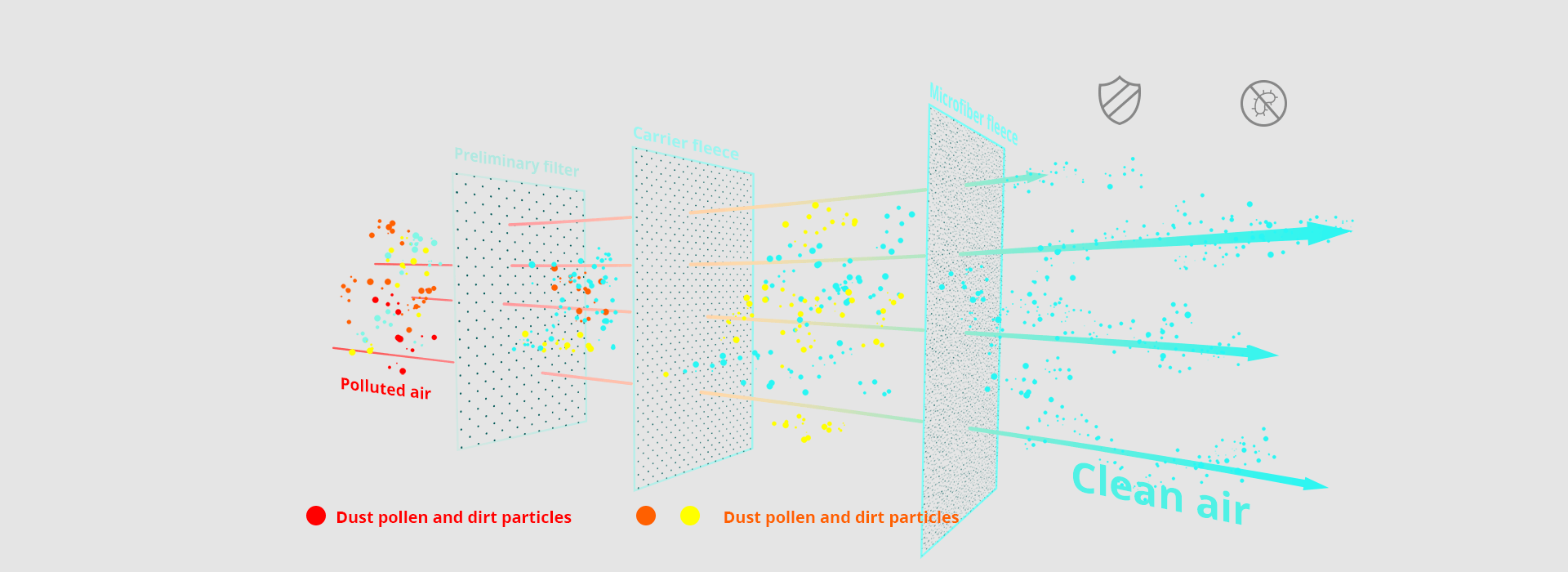

Air purifiers typically incorporate various types of filters, each with unique functions and failure modes, dictating their respective maintenance cadences.

| Filter Type | Primary Function | Failure Mode | Maintenance Characteristics |

|---|---|---|---|

| Pre-filter | Captures large particles like dust, hair, lint | Physical blockage, airflow restriction | Washable or requires regular cleaning/replacement to protect subsequent filters |

| Activated Carbon | Adsorbs gaseous pollutants (VOCs, odors, formaldehyde) | Adsorption saturation, inability to adsorb further | Not washable; requires regular replacement to prevent off-gassing of adsorbed pollutants |

| HEPA (H11-H14) | Captures fine particles (PM2.5, bacteria, viruses) | Particle accumulation leading to increased pressure drop, reduced airflow, higher energy consumption | Not washable; requires replacement as it's the core of purification |

Key Call-outs:

- Blockage: Pre-filters primarily fail due to physical blockage, leading to a noticeable reduction in airflow.

- Adsorption Saturation: Activated carbon filters remove gaseous pollutants through adsorption. Once their adsorption sites are saturated, they lose effectiveness and can even "desorb" previously captured pollutants back into the air.

- Pressure-Drop Spike: As HEPA filters capture particles, the internal spaces within the filter media gradually fill up, increasing the resistance to airflow (known as pressure drop). When this pressure drop reaches a certain threshold, the fan must work harder, consuming more energy to maintain the same airflow, or the airflow itself will significantly decrease, impacting purification efficiency.

Understanding these distinct failure modes is crucial for developing a precise maintenance plan.

Smart Sensors & Algorithms Rewrite the Schedule

Bid farewell to vague, calendar-based maintenance and embrace intelligent, precise management. Modern air purifiers are integrating advanced sensors and algorithms to provide dynamic, personalized filter replacement reminders.

- Pressure Sensors: These sensors continuously monitor the pressure difference across the filter. As the filter accumulates dust, this pressure difference gradually increases. When it reaches a pre-set threshold, the system triggers a replacement alert.

- Fan Current Feedback: The electrical current consumed by the fan is directly related to the air resistance it encounters. When a clogged filter increases resistance, the fan draws more current to maintain its speed. The system can monitor these current changes to assess filter status.

- Particulate Counters: Some high-end air purifiers include built-in particulate sensors that monitor the air quality after it passes through the filter. If the particle concentration at the outlet increases, it may indicate filter failure or bypass, necessitating replacement.

Data from these sensors is fed into sophisticated cloud-based models. Combined with user habits and environmental air quality data, machine learning algorithms analyze this information to accurately predict filter lifespan.

Benefit: This intelligent system can dynamically adjust filter replacement dates by up to ±40% based on the actual usage patterns of each home or facility. This means you no longer have to guess; instead, you rely on real data for maintenance, avoiding premature replacements that lead to waste and preventing decreased purification efficiency from overdue filters.

HisoAir - HA374 with filter replacement reminder function

An increase in filter pressure drop isn't just about purification efficiency; it's also a significant, often overlooked, energy consumption issue.

For every +20 Pa increase in filter resistance, your air purifier's motor may consume approximately 3-5% more power, accompanied by higher operating noise.

This isn't just theoretical. Imagine your air purifier, with a clogged filter, working harder to maintain its rated Clean Air Delivery Rate (CADR). The fan strains, producing more noise, and consuming more electricity. Over time, this additional power consumption adds up to a considerable expense.

Therefore, prompt filter replacement, especially when pressure drop noticeably increases, is not merely about maintaining indoor air cleanliness; it's an energy-savings play. It ensures your device operates at peak efficiency, reduces long-term running costs, and provides a quieter user experience.

The Game-Changer: High-Dust-Holding-Capacity (HDHC) Filters

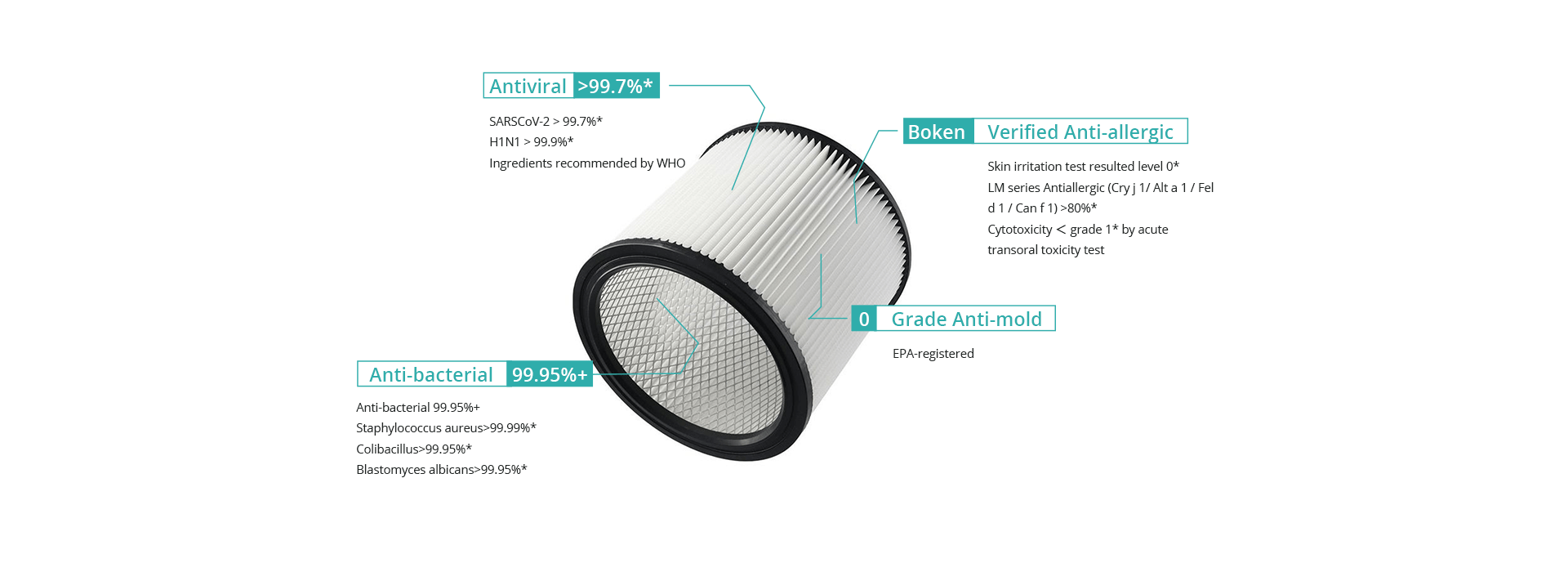

In response to escalating air pollution challenges and users' desire for longer filter life, High-Dust-Holding-Capacity (HDHC) filters have emerged as a true "game-changer" in air purification.

HDHC filters don't simply rely on thicker media; they incorporate a series of precise engineering designs to significantly enhance their dust-holding capability:

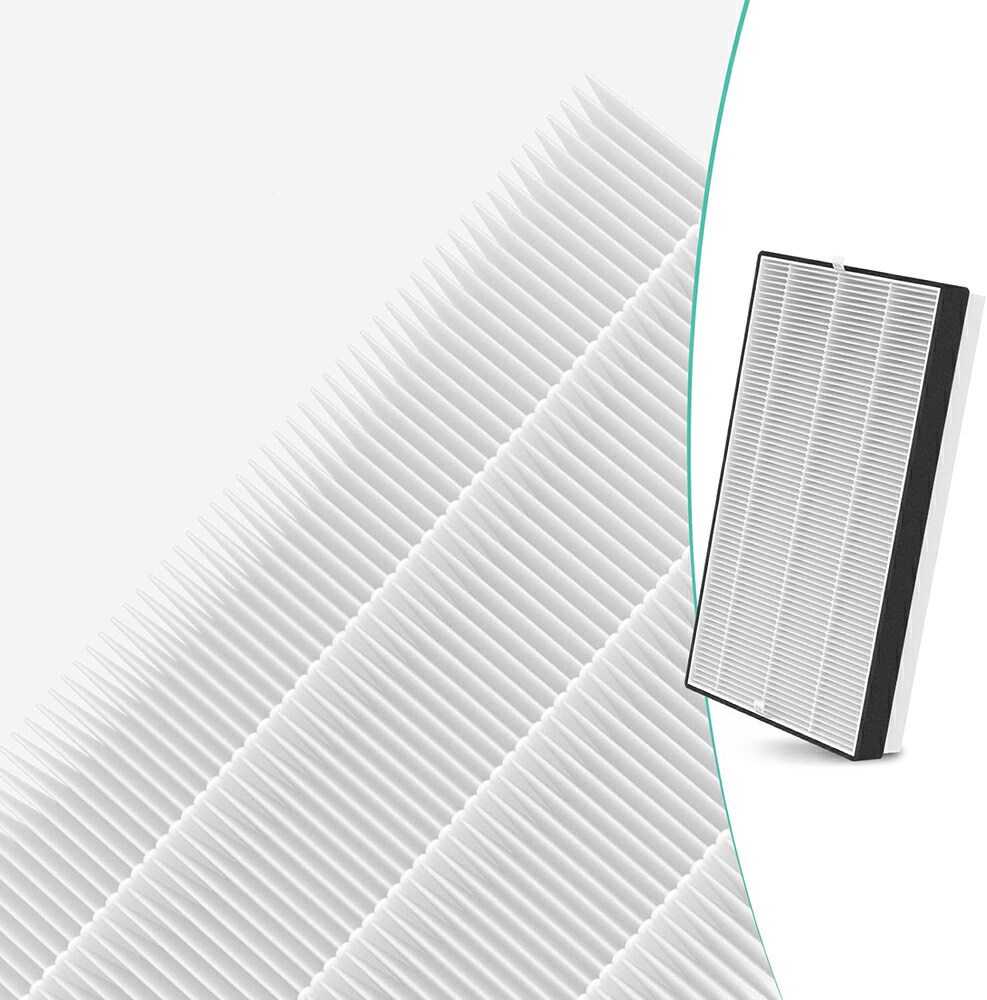

- Gradient Fiber Structure: The filter media's fiber density gradually increases from the air inlet side to the outlet side, creating a "gradient." This allows particles of different sizes to be captured at varying depths within the media, more efficiently utilizing the filter's volume.

- Electrostatic Charge Technology: Permanent electrostatic charges are introduced into the filter media. These charges attract and capture even tiny particles that might not directly impact the fibers, greatly improving both capture efficiency and dust-holding capacity.

- Deep Pleat Design: By increasing the depth and number of pleats in the filter, the surface area of the filter media is vastly expanded within a limited volume, providing significantly more space for dust accumulation.

These "engineering tricks" enable HDHC filters to store 2-4 times more dust while only incurring an initial resistance increase of approximately 10-15 Pa. This translates to a significantly extended filter lifespan with minimal impact on device performance.

Lab Data Example: A 300 g/m² HDHC H13 HEPA filter ran until 200 Pa after trapping 250 g of dust. In contrast, a standard H13 filter might reach the same pressure drop after capturing only 100 g of dust. This means the HDHC filter lasted approximately 6 weeks longer, or even more, than a standard filter under comparable conditions.

HDHC filters are particularly ideal for environments with stringent air quality requirements and where downtime is costly, such as:

- Intensive Care Units (ICUs): Ensuring sterile air for patients, reducing filter replacement frequency can lower cross-contamination risks.

- Airport Terminals: High foot traffic and numerous pollution sources mean HDHC filters can effectively handle heavy operational loads.

- Pollution-Heavy Cities: In areas prone to smog, HDHC filters significantly extend replacement cycles, easing the maintenance burden on users.

Total Cost of Ownership Beats the Sticker Price

When selecting air purifier filters, focusing solely on the "sticker price" is short-sighted. The true economic benefit lies in the Total Cost of Ownership (TCO). The TCO formula can be simplified as:

TCO = (Filter Price × Replacement Frequency) + Energy Consumption + Labor & Maintenance Costs

Let's examine how HDHC filters "flip the economics" through TCO:

While the initial purchase price of an HDHC filter might be slightly higher than a standard filter, its extended lifespan means a significantly lower replacement frequency. This directly reduces the "Filter Price × Replacement Frequency" component of the cost.

Crucially, HDHC filters maintain a lower pressure drop throughout their longer service life, leading to reduced fan energy consumption. This "Energy Consumption" saving, over the long run, can be substantial.

For commercial users, such as air purifier rental or subscription service providers, the advantages of HDHC filters are even more pronounced. Longer filter life translates to fewer on-site service visits, which dramatically lowers "Labor & Maintenance Costs." This not only boosts operational efficiency but also directly improves gross margins.

Return on Investment: Many case studies show that the incremental cost of HDHC filters often pays back within 9-12 months through saved energy and maintenance expenses. In the long term, HDHC filters consistently prove to be the more economical and sustainable choice.

Conclusion

Through this discussion, we hope you've gained a clear understanding:

- Smart monitoring tells you when to change your filter: Move beyond guesswork and rely on precise, sensor- and algorithm-driven insights for optimal filter maintenance.

- HDHC technology tells you how seldom you need to change it: Embrace high-dust-holding-capacity filters to significantly extend filter lifespan, reduce replacement frequency, and lighten your maintenance load.

Combining smart monitoring with HDHC technology is the golden standard for achieving efficient and economical air purification.