Your "smart" product is getting lost in a sea of competitors. Everyone has an app. You need a real, lasting advantage that customers can feel and competitors can't copy.

True innovation in wellness tech comes from the physical product itself, not just the software. Advancements in material science1 and manufacturing processes create products that are more durable, hygienic, and user-friendly. This "hard tech" innovation is what builds a defensible brand and earns 5-star reviews.

I've spent my entire career in the mold and manufacturing industry. I've seen brilliant product ideas succeed or fail based on one thing: the quality of the physical object. We've all become obsessed with "smart" features, thinking an app is the key to success. But I've seen too many brands fall into this trap, only to be crushed by bad reviews about the product itself. It's time we look deeper.

The real, lasting innovation isn't just coded, it's forged, molded, and engineered. It's the kind of innovation you can hold in your hand. Let's explore how this "hard innovation" is the true engine for the next wave of successful products.

Software development is now a commodity, with app developers readily available globally.True

Platforms like Upwork, Toptal, and Fiverr have made it easier and more affordable than ever to hire skilled software developers, lowering the barrier to entry for creating a 'smart' product app.

All 'smart' products require a custom-developed app to function.False

Many 'smart' products can leverage existing platforms like Apple HomeKit, Google Home, or Amazon Alexa, reducing the need for a fully custom-built application from scratch.

1. What Does "Tech Innovation" Really Mean in 2025?

Your team spent months developing a clever app. But on launch day, you see three other brands with the exact same features. Your "innovation" just became a commodity overnight.

In 2025, "tech innovation" must be redefined. It's not about easily copied software or "smart" features. It's about "hard tech2"—advancements in materials, tooling, and manufacturing processes that create a fundamentally better and more defensible physical product. This is the new competitive high ground.

For years, we've been told that "tech" means software. As a mold and manufacturing guy, I've watched this trend closely. I see product designers like you, Jacky, under pressure to add more "smart" features. But the market is saturated. When everyone has an app, the app is no longer a differentiator. It's just a basic expectation. The real opportunity for you to stand out and create value is by shifting your focus. You need to move from "Soft Tech" to "Hard Tech."

Soft Tech vs. Hard Tech

- Soft Tech: This is the software, the app, the cloud connectivity. It's important for the user interface, but it has a low barrier to entry. A competitor can copy your app's features in a matter of weeks. It's not a strong defense for your brand.

- Hard Tech: This is the physical world. It's material science, process engineering, and custom tooling. It's developing a product that is physically superior. This is difficult, expensive, and takes real expertise. Because it's hard, it's also highly defensible. It's your moat.

The average cost to develop a simple mobile app is over $100,000.False

While complex apps can cost hundreds of thousands, many simple MVP (Minimum Viable Product) apps can be developed for between $15,000 and $50,000, making them relatively accessible.

Patents for manufacturing processes provide stronger long-term protection than software copyrights.True

Utility patents on a unique manufacturing process or mechanical invention can block competitors for 20 years, whereas software copyright only protects the specific code, not the functional idea, which can be easily replicated with different code.

2. The "Software Trap": When a "Smart" Product Fails?

Your product has a beautiful app and amazing smart features. But the reviews are terrible. Customers complain it's flimsy, hard to clean, or breaks easily. The "smart" part didn't matter.

The "Software Trap" is focusing on app features while neglecting the core physical product. A buggy app can be fixed with an update. A poorly manufactured product leads to returns, bad reviews, and permanent brand damage. The user experience3 is rooted in the physical object.

I remember a client a few years ago. They had a brilliant idea for a "smart" kitchen gadget. They spent 80% of their R&D4 budget on the app and cloud platform. The physical product was an afterthought, made with standard, cheap plastic injection molding to save costs. The app was slick, but the product felt cheap. Worse, a small plastic hinge would snap after a few months of use. The 1-star reviews poured in, all saying the same thing: "Great idea, terrible quality." The company folded within a year.

This is a story I've seen again and again. Your target user, Jacky, knows this pain. You can design the most elegant form, but if the manufacturing process leads to a weak point or a material that degrades, the entire user experience is compromised.

The Real Source of User Experience (UX)

| UX Factor | "Soft Tech" Influence | "Hard Tech" Influence |

|---|---|---|

| First Impression | App onboarding, UI design | Feel, weight, material finish, build quality |

| Daily Use | Feature accessibility, notifications | Ergonomics, durability, ease of cleaning |

| Long-Term Value | Software updates, new features | Resistance to wear, hygiene5, reliability |

| Brand Trust | Data privacy, app stability | Product safety, longevity, physical integrity |

Over 50% of 1-star app reviews are related to software bugs or crashes.True

Studies of app store reviews consistently show that technical issues like crashes, freezes, and bugs are the primary driver of negative user feedback for software.

A product's physical durability is the number one driver of long-term customer satisfaction.False

While durability is a major factor, overall customer satisfaction is a complex metric that also includes performance, ease of use, customer service, and price. There is no single number one driver for all products.

3. The "Hard Innovation": Material Science & Process Engineering?

You want to build a product that feels premium and lasts a lifetime. You're tired of designing for standard plastic parts that feel cheap. Where can you find a real competitive edge?

"Hard Innovation" is found in material science and process engineering. It's about choosing a superior material like stainless steel and mastering a complex process like deep-drawing6. This creates tangible benefits—hygiene, durability, and a premium feel—that software can't replicate.

When I started on the factory floor, I learned a simple lesson: the material and the process define the product. You can't make a strong part from a weak material. You can't achieve a seamless finish with a sloppy process. This is where true masters of the craft, like you Jacky, can shine. Instead of just asking "What can we do with this plastic?", the better question is "What is the absolute best material and process for this user experience?".

This is where the real R&D happens. It's not about coding; it's about metallurgy, polymer science, and fluid dynamics. It's about designing and building multi-million dollar tooling that can shape metal with sub-millimeter precision.

The Power of Process

- Injection Molding: Great for complex shapes and low-cost mass production. But it creates seams, requires porous plastics, and can have issues with part strength and chemical leaching.

- Deep-Drawing Steel: A more advanced process. It stamps a single sheet of metal into a seamless, non-porous form. It's more expensive upfront but results in a product that is incredibly durable, hygienic, and easy to clean.

This is the "Hard Tech" advantage. It's not something a competitor can decide to do next week. It requires deep expertise, massive capital investment, and a long-term vision.

316L stainless steel is completely non-porous, preventing bacteria from growing within the material itself.True

Unlike plastics, medical-grade 316L stainless steel has a non-porous surface. This means microorganisms cannot penetrate the material, making it inherently more hygienic and easier to sterilize.

Deep-drawing metal is a new technology invented in the 21st century.False

Deep-drawing is a metal forming process that has been used for over a century, famously used to manufacture artillery shells and automotive parts. However, modern advancements in CNC control and tooling have allowed for much greater precision.

4. Case Study: How a Stainless Steel Humidifier Wins?

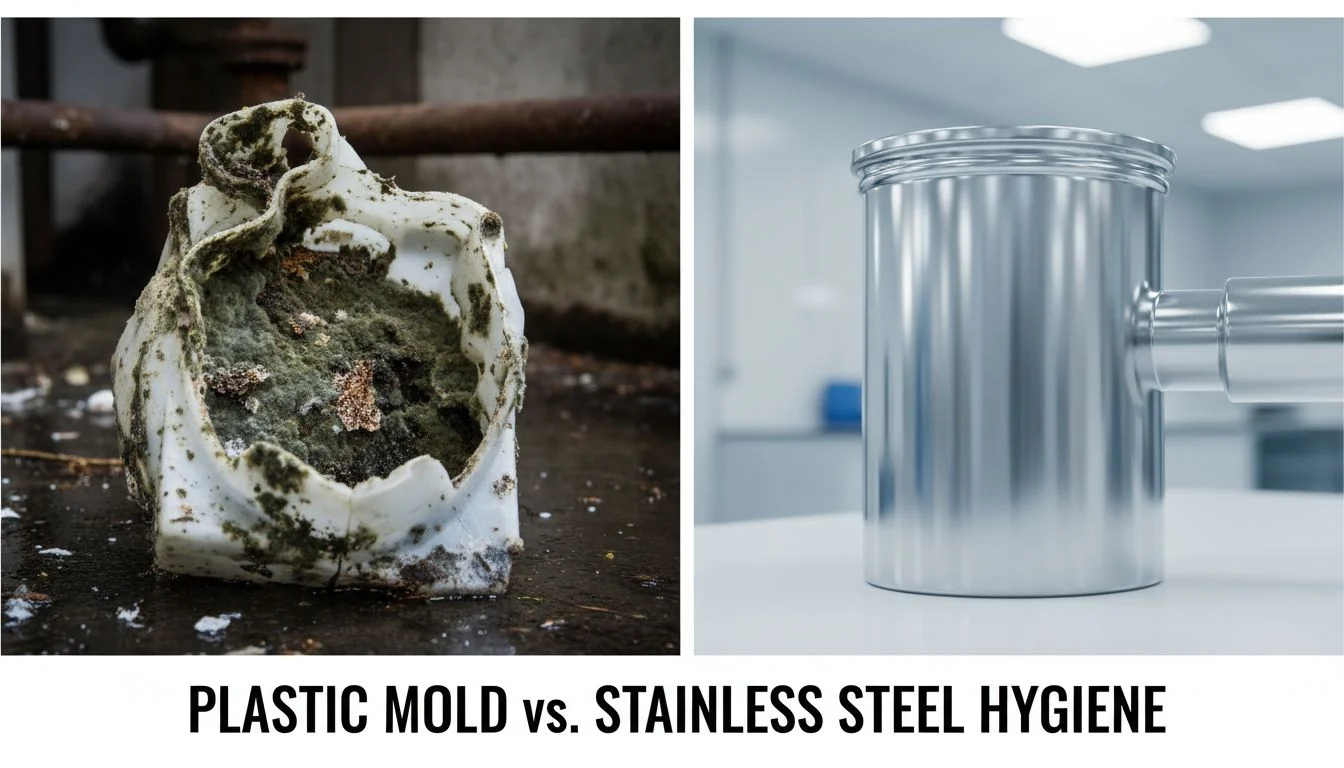

Imagine two humidifiers. One is plastic, gets moldy, and has 2-star reviews. The other is stainless steel, easy to clean, and has 5-star reviews. What's the real difference between them?

The difference is manufacturing innovation. The plastic humidifier uses standard injection molding, creating a porous surface perfect for mold. The stainless steel humidifier uses advanced deep-drawing to create a seamless, non-porous tank that is ultra-hygienic and earns customer trust.

This is the clearest example I can give. For years, every humidifier was made of plastic. It was cheap and easy. But customers all had the same complaint: mold. No matter how "smart" the humidifier was, the user experience was ruined by the constant need to scrub slimy, moldy plastic. The manufacturing choice directly led to a bad UX.

Then, a few innovative brands appeared. They asked a better question: "How do we make a truly hygienic humidifier?" The answer wasn't an app. It was material science. They chose 316L stainless steel—the same material used in surgical tools. And they used a deep-drawing process to form the water tank from a single, seamless piece.

From Manufacturing Process to 5-Star Review

- Manufacturing Choice: Ditch plastic injection molding. Use deep-drawing for 316L stainless steel.

- Product Attribute: The water tank is now seamless, non-porous, and corrosion-resistant.

- User Benefit: The tank is incredibly easy to clean. Mold and bacteria have nowhere to hide. It's fundamentally more hygienic.

- The 5-Star Review: "Finally, a humidifier that's actually easy to clean! I don't have to worry about mold anymore. Worth every penny."

The innovation wasn't the software. It was the manufacturing. That's the moat.

Plastic surfaces, even when smooth, contain microscopic pores where bacteria can colonize.True

Most common plastics like ABS and Polypropylene are porous on a microscopic level, which can trap moisture and provide a breeding ground for bacteria and mold, making them difficult to fully sterilize.

All humidifiers on the market are now made of stainless steel.False

The vast majority of humidifiers are still made from plastic due to the lower manufacturing cost. Stainless steel models represent a premium, but growing, segment of the market.

5. Why Is "Manufacturing Innovation" Your Brand's Greatest "Moat"?

Your competitor just copied your app's killer feature. Your marketing advantage is gone. How do you build a business that's truly defensible and can't be easily replicated by others?

Your "moat" is your manufacturing process. An app can be copied in a month. A unique, patented physical product built with specialized tooling and deep engineering expertise can take competitors years and millions of dollars to even attempt to replicate. That is true defensibility.

In business, we talk a lot about building a "moat"—a competitive advantage7 that protects your company from attack. For a direct-to-consumer (D2C) brand, this is everything. For too long, brands have thought their moat was their logo, their marketing, or their app. These are fragile defenses.

The strongest, widest, and deepest moat you can build is "Hard Tech." Think about the stainless steel humidifier. For a competitor to copy it, they can't just hire a few app developers. They would need to:

- Gain expertise in metallurgy and the deep-drawing process.

- Invest millions of dollars in custom tooling and machinery.

- Spend 1-2 years in R&D to perfect the process and pass compliance.

By the time they launch, you're already two years ahead, working on the next "Hard Tech" innovation. You're not competing on price or features; you're competing on a fundamentally superior product. This is how you build a brand that lasts. This is how you sell a product for a premium and own a category. As a designer, Jacky, championing this approach makes you invaluable. You're not just designing a product; you're designing the company's future.

The cost of custom tooling for deep-drawing steel can exceed $500,000.True

Complex, high-precision dies for deep-drawing large metal parts are extremely expensive to design, machine, and test, often representing a significant capital investment for a new product line.

A strong brand is the only moat a company needs.False

While brand is a powerful moat, it's most effective when combined with other moats like network effects, high switching costs, or proprietary technology. A brand without a superior product or process is vulnerable.

6. How to Partner with a True Innovator, Not Just an Assembler?

You have a great idea for a next-gen product. But you don't have the $1M+ and 2 years needed for the "Hard Tech" R&D. How do you bring your vision to life?

You partner with a true manufacturing innovator. Find a partner who has already done the heavy lifting—the R&D, the tooling, the engineering. They aren't just an assembler; they are an enabler who gives you access to "Hard Tech" innovation from day one.

The path of "Hard Tech" innovation can seem daunting. The costs and timelines are significant. But you don't have to do it alone. The smartest brands don't reinvent the wheel. They find partners who have already built the engine. There are manufacturing partners out there—I've built my career helping companies find them—who are more than just assemblers. They are innovation hubs.

These partners, let's call them "Enablers" like Hisoair, have already invested the millions in tooling and the years in R&D. They have mastered the complex processes. They hold the patents8. They offer a platform of "Hard Tech" that you can build your brand on.

Assembler vs. Innovator Partner

| Aspect | Standard Assembler | True Innovator Partner |

|---|---|---|

| Focus | Low-cost assembly | High-value engineering |

| Offering | "We can build your design." | "We have a technology platform you can use." |

| Value | Labor cost savings | Speed to market, defensibility, R&D access |

| Relationship | Transactional | Collaborative partnership |

By partnering with a true innovator, you get to launch a next-generation product without the prohibitive upfront cost and risk. You can focus on what you do best—branding, marketing, and connecting with customers—while standing on a foundation of defensible, meaningful "Hard Tech" innovation.

ODM (Original Design Manufacturer) partners offer pre-engineered product platforms that brands can customize.True

Many manufacturers operate on an ODM model, where they have already developed core product technologies and designs that other companies can license and re-brand, significantly reducing R&D time and cost.

All manufacturing partners in Asia are simple assemblers.False

This is a common misconception. Many advanced manufacturers in Asia and globally are highly sophisticated innovation partners with extensive R&D departments, proprietary technologies, and robust engineering capabilities.

Conclusion

Stop chasing fleeting software features. True, defensible innovation lies in the physical product. Partner with a manufacturing expert to build your moat and create a product that customers will truly love.

References

-

Understanding material science can lead to innovative product designs that enhance durability and user experience. ↩

-

Exploring hard tech reveals how physical innovations can create competitive advantages in product development. ↩

-

Exploring user experience factors can help you design products that meet customer needs and expectations. ↩

-

Understanding the importance of R&D can help you prioritize investments that lead to successful product development. ↩

-

Understanding the relationship between materials and hygiene can improve product safety and customer satisfaction. ↩

-

Discovering the deep-drawing process can provide insights into creating seamless, high-quality products. ↩

-

Exploring strategies for competitive advantage can help you position your brand effectively in the market. ↩

-

Learning about patents can help you understand how to safeguard your innovations and maintain a competitive edge. ↩