Every groundbreaking product begins as a spark of an idea, a vision of something new that can solve a problem, enhance lives, or simply bring joy. However, the journey from a nascent concept to a tangible, market-ready product is often fraught with challenges. One of the most critical, yet frequently underestimated, hurdles is finding the right manufacturing partner. For businesses, whether you're a B2B enterprise looking to expand your product line or a D2C brand aiming to bring innovative solutions directly to consumers, the supplier you choose can make or break your venture. This guide is designed to illuminate the path, offering a comprehensive roadmap for identifying, evaluating, and collaborating with suppliers who can transform your product idea from scratch into a successful reality. We'll delve into the nuances of defining your product, understanding different supplier types, navigating the evaluation and sourcing processes, and ultimately, building enduring relationships that foster mutual growth and innovation.

Understanding Your Product Idea

Before seeking a supplier, thoroughly define your product. This includes detailed specifications, target audience, and production requirements. A clear understanding ensures effective communication with potential partners.

Define Product Specifications

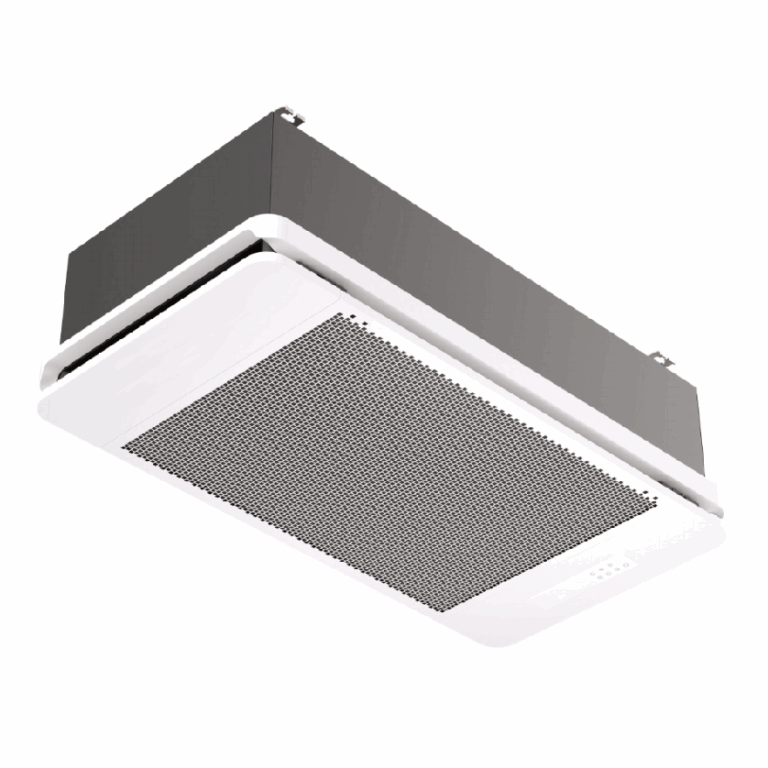

Detail materials, features, and quality standards. For an air purifier, specify filtration type (HEPA, UV-C), CADR, noise level, dimensions, and design. Document technical details, schematics, and IP considerations for clarity.

Identify Target Audience and Market Needs

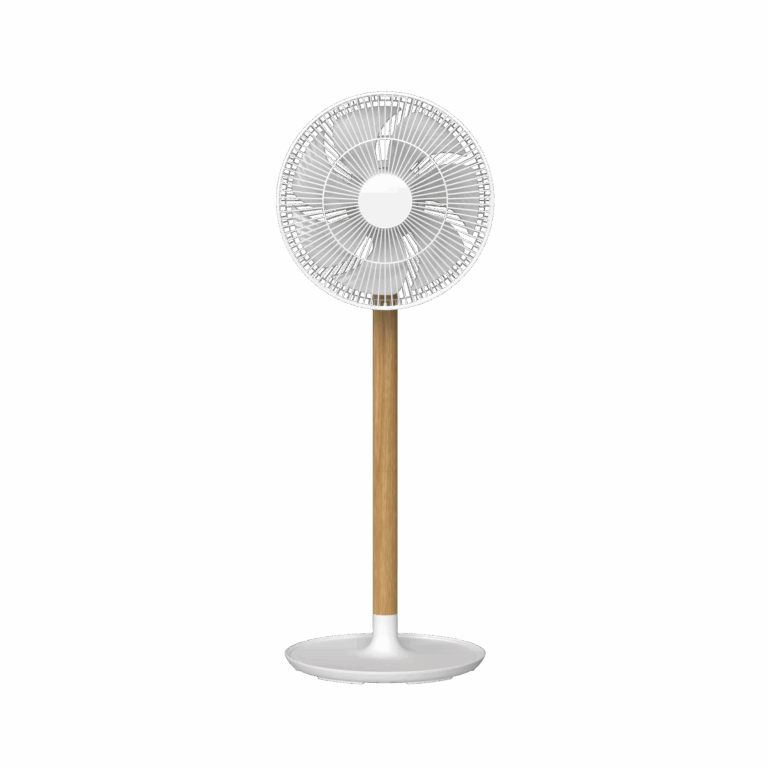

Understand your audience (B2B or D2C) to influence design and features. A B2B air purifier might prioritize performance, while a D2C humidifier focuses on aesthetics. Market analysis helps differentiate your product and identify opportunities.

Assess Production Requirements

Determine production scale (small batch or mass production) and product complexity. Small batches suit specialized manufacturers, while large volumes require high-capacity factories. Establish a realistic timeline for development, manufacturing, and delivery.

Types of Suppliers

Navigating the landscape of manufacturing partners can be complex, as various types of suppliers offer distinct services and cater to different needs. Understanding these distinctions is crucial for selecting the right partner for your product idea.

Manufacturers (OEM, ODM, CM)

Original Equipment Manufacturers (OEMs) are companies that produce parts and equipment that may be marketed by another manufacturer. When you work with an OEM, you provide the design and specifications, and they manufacture the product according to your exact requirements. This model is ideal if you have a fully developed product design and simply need a factory to produce it. OEMs are excellent for maintaining strict control over your product's intellectual property and design.

Original Design Manufacturers (ODMs), on the other hand, design and manufacture a product that is then rebranded by another firm for sale. If you have a product idea but lack the in-house design and engineering capabilities, an ODM can be a valuable partner. They offer a more comprehensive service, from design and development to manufacturing. While this can accelerate your time to market, it means less control over the product's core design and intellectual property, as the ODM often retains ownership of the original design.

Contract Manufacturers (CMs) are companies that manufacture products or components for other companies. They are often used for assembly, testing, and packaging. CMs are flexible and can handle various stages of the production process, making them suitable for businesses that want to outsource specific manufacturing tasks rather than the entire product development cycle. They are particularly useful for scaling production without investing in your own manufacturing facilities.

Sourcing Agents

Sourcing agents act as intermediaries between you and manufacturers, especially in foreign countries. They have extensive networks and expertise in identifying suitable suppliers, negotiating prices, overseeing quality control, and managing logistics. For businesses new to international sourcing or those with limited resources, a sourcing agent can be invaluable. They can help mitigate risks associated with language barriers, cultural differences, and unfamiliar business practices. However, it's essential to choose a reputable agent with transparent fees and a proven track record.

Freelance Designers/Engineers

For early-stage product development or highly specialized components, freelance designers and engineers can be excellent resources. They can help refine your product idea, create detailed designs, develop prototypes, and even assist with initial small-batch production. While they may not offer the large-scale manufacturing capabilities of a factory, their expertise can be critical in bringing a complex or innovative product to life before engaging with larger manufacturers. They are particularly useful for iterative design processes and proof-of-concept development.

Evaluating Potential Suppliers

Once you have a clear understanding of your product and the types of suppliers available, the next critical step is to rigorously evaluate potential partners. This process goes beyond simply comparing price quotes; it involves a holistic assessment of their capabilities, reliability, and compatibility with your business objectives.

Experience and Expertise

Look for suppliers with a proven track record in manufacturing products similar to yours. Experience in your specific industry (e.g., air purification, humidification, water treatment for Hisoair) is a significant advantage. Inquire about their past projects, client testimonials, and case studies. A supplier with relevant expertise will understand the nuances of your product, anticipate potential challenges, and offer valuable insights. Don't hesitate to ask for references and contact their previous clients to verify their claims and assess their performance.

Quality Control and Certifications

Quality is non-negotiable. A reliable supplier should have robust quality control (QC) processes in place at every stage of production, from raw material inspection to final product testing. Ask about their QC protocols, the equipment they use, and their defect rates. Certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), CE, RoHS, or FCC are strong indicators of a supplier's commitment to quality and compliance with international standards. For products like air purifiers, specific certifications related to air quality and safety are crucial. Request copies of their certifications and audit reports.

Communication and Responsiveness

Effective communication is the cornerstone of any successful partnership. Assess how responsive potential suppliers are to your inquiries. Do they answer your questions thoroughly and promptly? Do they have a dedicated English-speaking contact person or team? Clear and consistent communication is vital for managing expectations, resolving issues, and ensuring that your project stays on track. A supplier who is proactive in providing updates and transparent about challenges is far more valuable than one who is difficult to reach or evasive.

Pricing and Payment Terms

While price shouldn't be the sole determinant, it's undoubtedly a significant factor. Obtain detailed quotes that break down costs, including unit price, tooling costs, shipping, and any other associated fees. Compare quotes from multiple suppliers, but be wary of unusually low prices, which can often indicate compromises in quality or ethical practices. Negotiate payment terms that are fair and manageable for both parties. Standard terms often involve an upfront deposit, progress payments, and a final payment upon completion or delivery. Ensure all financial agreements are clearly documented in a contract.

Production Capacity and Lead Times

Evaluate a supplier's production capacity to ensure they can meet your volume requirements, both initially and as your business scales. Ask about their current production schedule and how they handle peak seasons or unexpected surges in demand. Understanding their lead times – the time from order confirmation to product delivery – is crucial for your inventory management and market planning. Request a realistic production timeline for your specific product, including prototyping, tooling, manufacturing, and shipping. A supplier with flexible capacity and reliable lead times can help you avoid costly delays and missed market opportunities.

The Sourcing Process

With a clear understanding of your product and a refined list of potential suppliers, the next phase involves the practical steps of engaging with these partners. This sourcing process is a structured approach to move from initial contact to a finalized manufacturing agreement.

Research and Shortlisting

Begin by conducting thorough research on the shortlisted suppliers. Utilize online directories, trade show contacts, industry associations, and professional networks. Websites like Alibaba, Made-in-China, and ThomasNet can be good starting points, but always cross-reference information. Look for detailed company profiles, product catalogs, and any available public information about their operations and client base. Pay attention to their specialization – do they focus on air purification, humidification, or water treatment, aligning with Hisoair's core business? Based on your evaluation criteria (experience, quality, communication, etc.), narrow down your list to a manageable number, typically 3-5 suppliers, for deeper engagement.

Request for Quotation (RFQ) and Samples

Once you have your shortlist, issue a comprehensive Request for Quotation (RFQ). This document should include all your product specifications, desired quantities, quality standards, packaging requirements, and delivery timelines. The more detailed your RFQ, the more accurate the quotes you will receive. Ask for a breakdown of costs, including unit price, tooling costs, minimum order quantities (MOQ), and payment terms. Simultaneously, request samples or prototypes. This is a crucial step to assess the supplier's manufacturing capabilities and the quality of their work firsthand. Test these samples rigorously against your specifications. Be prepared to pay for samples, as this demonstrates your seriousness as a potential client.

Due Diligence and Background Checks

Before committing to a supplier, conduct thorough due diligence. This involves verifying their legal registration, business licenses, and financial stability. For international suppliers, consider using third-party inspection services to audit their factory, assess their production processes, and verify their compliance with labor and environmental standards. Look for any red flags, such as a history of legal disputes, poor reviews, or inconsistent information. A site visit, if feasible, can provide invaluable insights into their operations, working conditions, and overall professionalism. This step is critical to mitigate risks and ensure you are partnering with a legitimate and reliable entity.

Negotiation and Contract

Once you've identified your preferred supplier, enter into negotiations. This isn't just about price; it's about establishing mutually beneficial terms. Discuss lead times, payment schedules, intellectual property protection, warranty, and dispute resolution mechanisms. Be clear about your expectations and ensure all agreements are documented in a legally binding contract. The contract should cover all aspects of the manufacturing agreement, including product specifications, quality standards, delivery schedules, pricing, payment terms, intellectual property rights, confidentiality clauses, and termination conditions. It's highly advisable to have a legal professional review the contract, especially for international agreements, to protect your interests.

Building and Maintaining Supplier Relationships

Finding the right supplier is only half the battle; cultivating a strong, collaborative relationship is equally vital for long-term success. A good supplier relationship can lead to better pricing, preferential treatment, faster problem resolution, and access to innovation.

Communication and Feedback

Open and consistent communication is the bedrock of any healthy relationship. Provide constructive feedback, both positive and negative, to your supplier. If there are issues with quality or delivery, address them promptly and professionally, focusing on solutions rather than blame. A supplier who feels valued and understands your evolving needs is more likely to go the extra mile for your business.

Problem Solving and Conflict Resolution

Inevitably, challenges will arise. Adopt a collaborative problem-solving approach. Work together to identify the root cause of issues and develop mutually agreeable resolutions. A supplier who is willing to openly discuss problems and actively participate in finding solutions is a true partner.

Long-term Partnership

View your supplier as a long-term partner. Share your long-term vision and upcoming product plans. This transparency can enable your supplier to better anticipate your needs and proactively suggest improvements or innovations. A strong, enduring partnership can lead to significant benefits, including cost efficiencies, improved product quality, faster development cycles, and a competitive edge in the market. For Hisoair, fostering such relationships with manufacturers of air purifiers, humidifiers, and water treatment products ensures a steady supply of high-quality components and finished goods, supporting both B2B and D2C growth.

Conclusion

The journey from a product idea to a market-ready reality is complex, but finding the right supplier is arguably the most critical step. This guide has walked you through the essential stages: understanding your product's specifications and market, identifying the various types of suppliers (OEMs, ODMs, CMs, sourcing agents, freelancers), rigorously evaluating potential partners based on experience, quality, communication, pricing, and capacity, and navigating the sourcing process from research to contract negotiation. Finally, we emphasized the importance of building and maintaining strong, collaborative relationships with your chosen suppliers.

Ultimately, the success of your product hinges on the strength of your supply chain. A well-chosen supplier is more than just a manufacturer; they are a strategic partner who can bring your vision to life, ensure quality, and support your growth. For B2B enterprises and D2C brands alike, investing time and effort in selecting the right manufacturing partner will pay dividends in product excellence and market success.

Ready to transform your product idea into a tangible reality? Contact Hisoair today for expert guidance and reliable manufacturing solutions in air purification, humidification, and water treatment. Let's build innovative products together.