In today's rapidly evolving market, transforming a brilliant idea into a tangible, successful product can seem like a daunting task. This is especially true in the dynamic indoor air quality (IAQ) sector, where innovation, technology, and consumer demands are constantly shifting. For businesses, startups, and entrepreneurs looking to make their mark with air purifiers, humidifiers, diffusers, or dehumidifiers, understanding the product development lifecycle is paramount. This comprehensive guide, tailored for the year 2025, will walk you through the essential steps to bring your indoor air quality product idea to life, from initial concept to mass production. We'll explore how to navigate market research, design, engineering, and manufacturing, with a special focus on leveraging expert OEM/ODM partnerships like HisoAir to streamline your journey and ensure your product stands out in a competitive landscape.

Step 1: Identifying Customer Needs and Market Research – The Foundation of Innovation

Every successful product begins with a deep understanding of customer needs and a thorough analysis of the market. In the indoor air quality (IAQ) industry, this means going beyond just creating a device; it means addressing specific pain points related to air quality, health, and comfort. As HisoAir specializes in air purifiers, humidifiers, diffusers, and dehumidifiers, your product idea should aim to solve a real problem within these categories.

Documenting Customer Needs: Beyond Features to Benefits

The first crucial step is to meticulously document what your potential customers truly desire. This isn't merely about listing features, but about articulating the benefits your product will provide. For instance, instead of stating 'our air purifier has a HEPA filter,' focus on 'our air purifier provides relief for allergy sufferers by capturing 99.97% of airborne particles.' This shift in perspective ensures your product is customer-centric from its inception. This documentation, often referred to as a product specification, will serve as your guiding roadmap throughout the development process and even inform your marketing strategy.

In-depth Market and Competitive Analysis

Once you have a clear understanding of customer benefits, it's time to dive into market research. This involves a comprehensive analysis of your target market, potential customers, and, critically, your competition. Neglecting this step can lead to significant setbacks, as launching a product into an already saturated or misunderstood market can be costly. Key tactics for effective market research include:

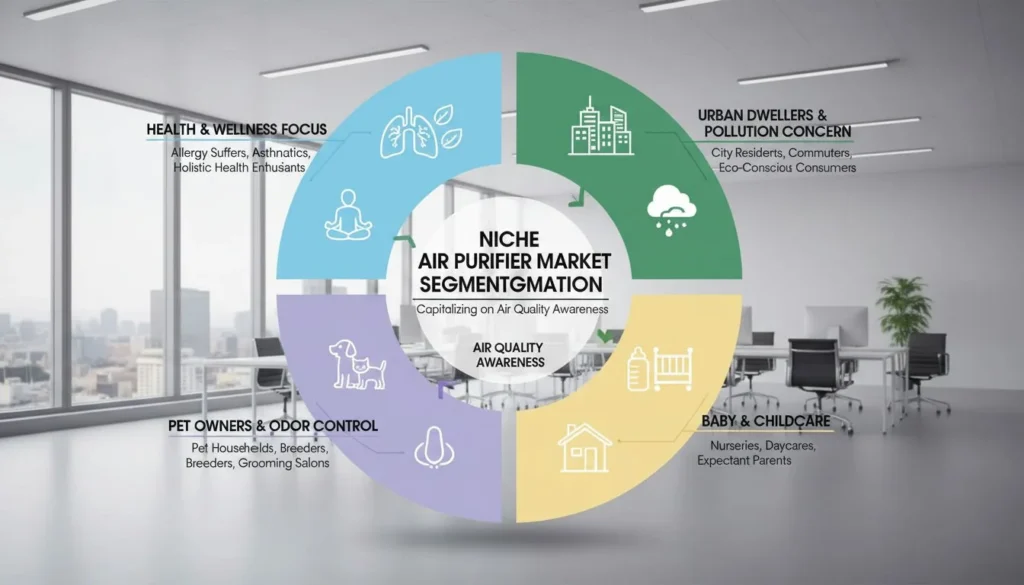

- Customer Profiles: Define your ideal customer. For HisoAir's products, this could range from individuals with respiratory issues to businesses seeking healthier indoor environments for their employees, or even smart home enthusiasts looking for integrated IAQ solutions.

- Consumer Interviews: Engage directly with your target demographic. Discuss their current challenges with indoor air quality, their expectations from such products, and their reactions to your proposed concept. Their feedback is invaluable for validating your ideas and uncovering unforeseen needs.

- Competitive Analysis: Identify existing products in the market that offer similar solutions. Analyze their strengths, weaknesses, pricing strategies, and market positioning. For example, if you're developing a new air purifier, research competitors' CADR (Clean Air Delivery Rate) performance, noise levels, filter lifespan, and smart features. HisoAir's expertise in 'Decibel Cancellation™ Technology' and 'Multiple Integrated Sensors Technology' highlights the importance of understanding technological differentiators in the market.

- Comparison Analysis: Beyond direct competitors, consider what alternatives customers currently use to address their IAQ concerns. This could be anything from opening windows to using plants for air purification. Understanding these alternatives helps you articulate the unique advantages of your product.

By rigorously conducting this research, you move beyond assumptions and build your product on a foundation of verified market insights. This iterative process should continue even as you develop prototypes, ensuring your product remains aligned with market demands and customer expectations.

Step 2: Product Design – Shaping Your Vision for Indoor Air Quality

With a solid understanding of customer needs and market dynamics, the next phase is to translate your vision into a tangible product design. This is where the abstract idea begins to take physical form, balancing aesthetics with functionality. For IAQ products like those HisoAir specializes in, design encompasses not just the external appearance but also the internal architecture that ensures optimal performance, user experience, and manufacturability.

Conceptualization and Ideation: Form Meets Function

Product design often begins with ideation, an interactive process of sketching and conceptualizing. This involves exploring various forms, layouts, and user interfaces. For an air purifier, this could mean considering different shapes (tower, console, wall-mounted), material finishes, and control panel designs. The goal is to create a product that is not only visually appealing but also intuitive to use and effective in its primary function – improving air quality. A great product seamlessly integrates form and function, where aesthetics enhance usability and performance.

When designing IAQ products, consider:

- Aesthetics and Integration: How will the product fit into various environments (homes, offices, hospitals)? Does it blend in or stand out? Modern consumers often prefer sleek, minimalist designs that complement contemporary interiors.

- User Interface (UI) and User Experience (UX): How easy is it for users to operate the device, change settings, or replace filters? Clear displays, responsive buttons, and intuitive app controls (especially for smart products) are crucial for a positive user experience.

- Portability and Placement: Is the product designed to be stationary or easily moved? For humidifiers or diffusers, ease of refilling water tanks is a key design consideration.

- 유지 관리: How simple is it to clean the device or replace components like filters? Designs that facilitate easy maintenance contribute to long-term customer satisfaction.

Balancing Innovation with Manufacturability

As you iterate on designs, it’s vital to keep manufacturability in mind. An innovative design is only successful if it can be produced efficiently and cost-effectively. This involves considering the types of materials, manufacturing processes (e.g., injection molding for plastic casings), and assembly methods. Early collaboration with manufacturing partners, like HisoAir, can provide invaluable insights into design for manufacturing (DFM) principles, helping to avoid costly redesigns later in the process.

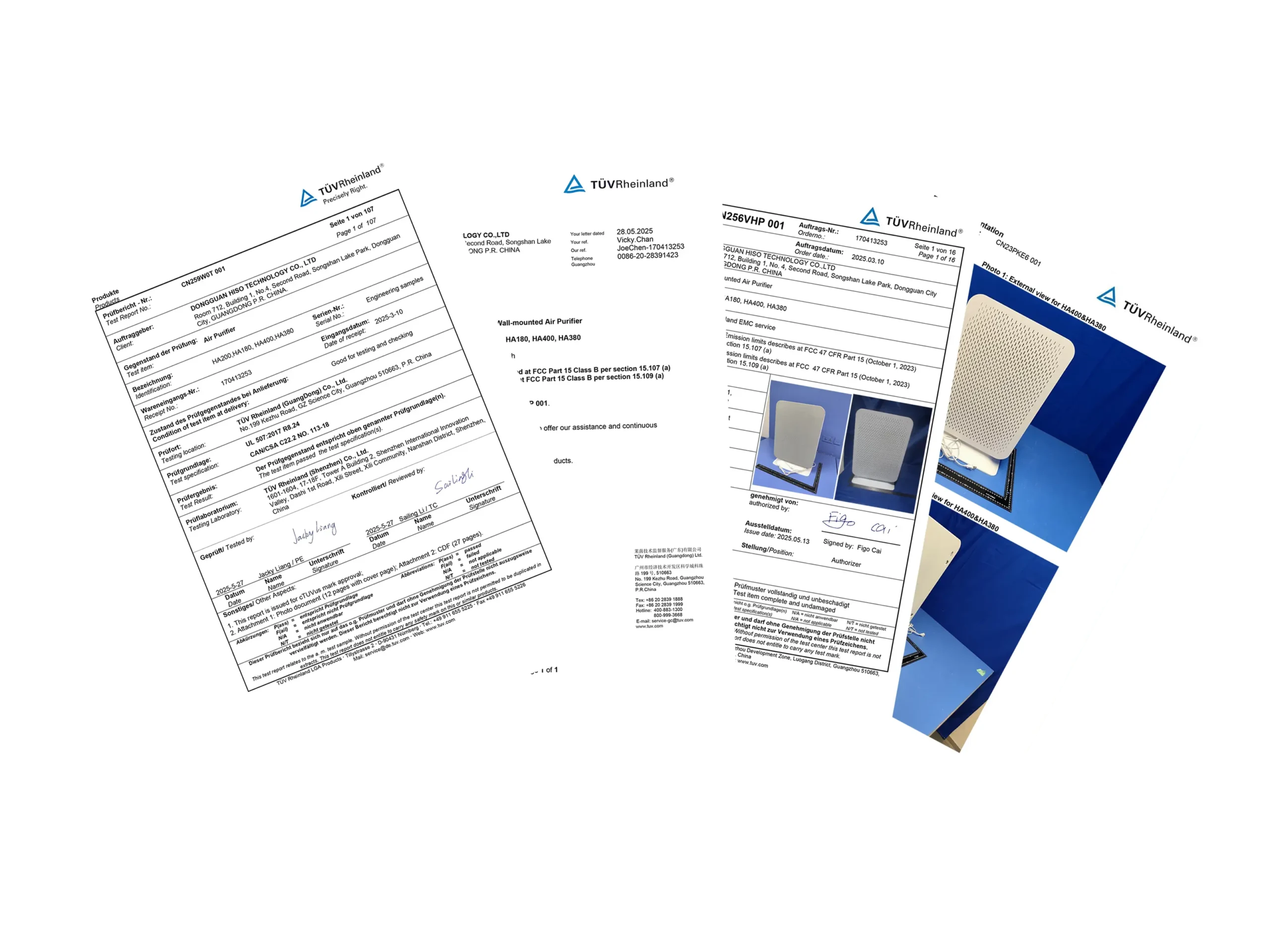

For example, HisoAir’s expertise in OEM/ODM manufacturing means they can guide you on material selection that meets both performance requirements (e.g., durability, air flow) and production efficiencies. Their experience with various certifications (ETL, FCC) also influences design choices to ensure compliance with international standards from the outset.

By carefully balancing creative design with practical manufacturing considerations, you can ensure your IAQ product not only looks good and performs well but can also be brought to market successfully.

Step 3: Engineering a Manufacturable New Product That Works – The Technical Blueprint

After the conceptual design phase, the product moves into detailed engineering. This is where the high-level ideas are translated into precise technical specifications, ensuring the product is not only functional but also manufacturable and reliable. For indoor air quality products, this involves meticulous attention to components, performance metrics, and system integration.

From Concept to Detailed Specifications

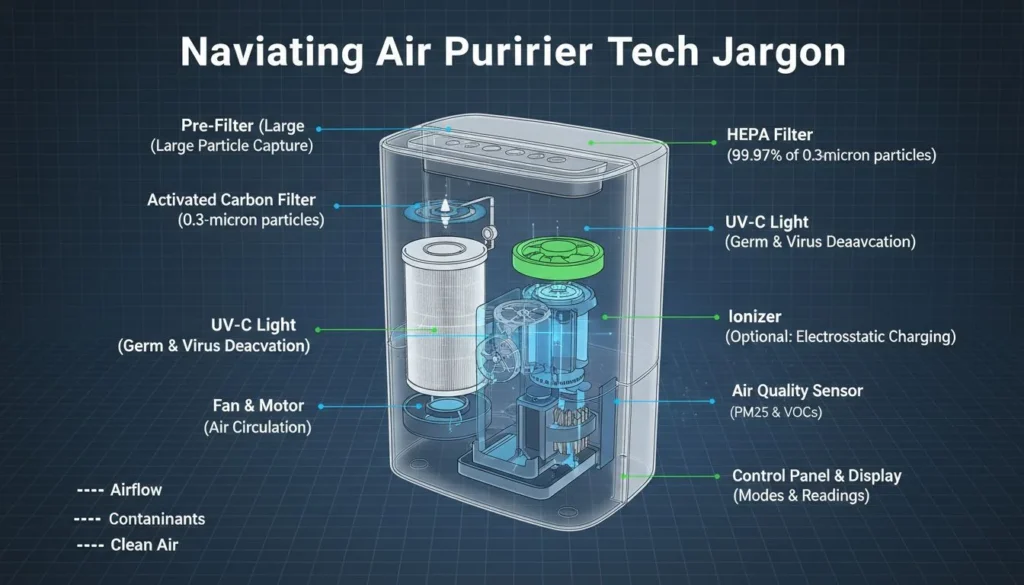

Engineering takes the design from a visual concept to a comprehensive blueprint. Every aspect of the product is defined, including its exact dimensions, internal components, material specifications, assembly methods, and operational parameters. For an air purifier, this would involve specifying the type and size of the fan, the filtration media (HEPA, activated carbon, pre-filters), the motor, control boards, sensors, and the housing materials. The goal is to define a product that can be consistently manufactured to meet performance and quality standards.

Key engineering considerations for IAQ products include:

- Airflow Dynamics: Designing the internal structure to optimize airflow through filters and ensure efficient air circulation. This directly impacts the Clean Air Delivery Rate (CADR), a critical performance metric for air purifiers.

- Noise Reduction: Incorporating acoustic design principles and materials to minimize operational noise. HisoAir's proprietary 데시벨 캔슬레이션™ 기술 is a prime example of advanced engineering focused on this aspect, achieving high CADR with whisper-silent operation.

- Sensor Integration and Accuracy: For smart IAQ devices, integrating various sensors (e.g., for PM2.5, VOCs, humidity, temperature) and ensuring their accuracy and reliability is paramount. This allows for intelligent operation and real-time air quality monitoring.

- Connectivity and Smart Features: Engineering the hardware and software for seamless integration with Wi-Fi, Matter™, Thread, or other smart home ecosystems. This includes designing robust communication modules and ensuring compatibility with various platforms.

- Durability and Longevity: Selecting materials and designing structures that can withstand continuous operation, environmental variations, and user handling. This includes considerations for filter lifespan and ease of replacement.

- Electrical Safety and Compliance: Ensuring all electrical components and systems meet international safety standards (e.g., ETL, FCC). This requires careful circuit design, component selection, and adherence to regulatory guidelines.

The Importance of Lean Product Development

During the engineering phase, applying principles of lean product development can significantly enhance efficiency and reduce waste. This involves continuous iteration, testing, and refinement, focusing on delivering maximum value to the customer while minimizing unnecessary complexity or cost. It encourages a mindset of constant improvement and problem-solving throughout the detailed design process.

Underestimating the effort required in engineering can lead to significant challenges down the line. A poorly engineered product may be difficult or impossible to manufacture as designed, or it may fail to meet performance expectations. Collaborating with experienced OEM/ODM partners like HisoAir, who possess deep engineering expertise in IAQ solutions, can mitigate these risks and ensure your product's technical blueprint is robust and ready for production.

Step 4: Finding Your Manufacturing Partners – The Key to Production Success

As your product’s engineering details solidify, a parallel and equally critical process begins: identifying and partnering with the right manufacturing partners. This step is not merely about finding someone to build your product; it’s about establishing a collaborative relationship that will significantly influence your product’s quality, cost, and time-to-market. For specialized indoor air quality products, selecting a manufacturer with proven expertise in this niche is paramount.

Why Early Engagement with Manufacturers Matters

It might seem premature to engage manufacturers while engineering is still underway, but early collaboration is crucial for several reasons. Manufacturers bring invaluable insights into Design for Manufacturability (DFM) and Design for Assembly (DFA). They can advise on material choices, production processes, and potential cost efficiencies that might not be apparent during the design phase. Without their input, you risk designing a product that is either too expensive to produce, difficult to assemble, or even impossible to manufacture at scale.

For instance, HisoAir, with over 20 years of experience as an OEM/ODM expert in indoor air quality solutions, offers multi-national production capabilities across China, Vietnam, Thailand, and Malaysia. This global footprint not only provides flexibility in supply chain management but also ensures adherence to diverse international standards and certifications. Partnering with such an established entity means you benefit from their existing infrastructure, quality control systems, and deep understanding of the IAQ product landscape.

Key Considerations When Choosing a Manufacturing Partner

When evaluating potential manufacturing partners for your air quality product, consider the following:

- Expertise in Your Product Category: Does the manufacturer have a strong track record in producing air purifiers, humidifiers, diffusers, or dehumidifiers? Their experience with specific components (e.g., filters, sensors, motors) and technologies (e.g., noise reduction, smart connectivity) is vital.

- Quality Control and Testing Capabilities: A reputable manufacturer will have rigorous quality control processes and in-house testing facilities. HisoAir, for example, boasts a CNAS-accredited laboratory with extensive testing capabilities for CADR, noise levels, filter efficiency, and safety. This ensures your product meets stringent performance and safety standards.

- Certifications and Compliance: Ensure the manufacturer can help your product achieve necessary global certifications (e.g., ETL, FCC) for your target markets. This is a complex area, and an experienced partner can navigate the regulatory landscape efficiently.

- Scalability and Production Capacity: Can the manufacturer scale production to meet your future demands? Discuss minimum order quantities (MOQs) and their ability to ramp up production as your product gains traction.

- Supply Chain Management: A strong manufacturing partner will have robust relationships with component suppliers and efficient supply chain management systems. This minimizes delays and ensures a steady flow of materials.

- Communication and Collaboration: Effective communication is key. Choose a partner who is transparent, responsive, and willing to collaborate closely throughout the development and production phases.

- Cost Structure: Obtain clear and detailed cost breakdowns. While cost is important, prioritize value, quality, and reliability over simply the lowest price.

By carefully selecting a manufacturing partner, you lay the groundwork for a smooth transition from design to mass production, significantly increasing your chances of a successful product launch.

Step 5: Building a Product Prototype, Testing, and Iteration – Refining Your Innovation

Once your product definition is solid and you’ve engaged with potential manufacturing partners, the next crucial step is to build prototypes. Prototyping is an iterative process of creating physical models of your product, testing them, and refining the design based on the results. This phase is invaluable for validating your design, gathering real-world feedback, and identifying potential issues before mass production.

The Purpose of Prototyping

A prototype serves multiple purposes:

- Visual Validation: It allows you to see and feel the product, assessing its aesthetics, ergonomics, and overall form factor. For IAQ products, this means evaluating how the device looks in a typical room setting, how easy it is to move, and the tactile feel of its controls.

- Functional Testing: Prototypes enable you to test the product’s core functionalities. For an air purifier, this would involve testing its CADR performance, noise levels, sensor accuracy, and connectivity features in various real-world scenarios. This is where HisoAir’s rigorous testing capabilities, including environmental chambers and noise testing, become critical.

- User Feedback: Providing prototypes to a select group of target users allows you to gather invaluable feedback on usability, performance, and overall satisfaction. This feedback can highlight areas for improvement that might not have been apparent during the design phase.

- Manufacturing Feasibility: Prototypes help manufacturing partners assess the ease of assembly, identify potential production challenges, and refine manufacturing processes. This is a key part of the Design for Manufacturing (DFM) process.

Types of Prototypes

Prototypes can range in complexity and fidelity:

- Rough Mock-ups: Simple, low-cost models (e.g., cardboard cutouts, 3D prints) used to explore basic form and size. These are excellent for early-stage ideation and quick visual checks.

- Functional Prototypes: More refined models that demonstrate key functionalities. These might not look exactly like the final product but are crucial for testing internal mechanisms, electronics, and software.

- Pre-production Prototypes: Highly refined prototypes that closely resemble the final product in terms of appearance, materials, and functionality. These are often used for final testing, certification, and marketing purposes.

The Iterative Process

Prototyping is rarely a one-time event. It’s an iterative cycle of:

- Build: Create a prototype based on the current design.

- Test: Put the prototype through rigorous functional and user tests.

- Analyze: Evaluate the test results and user feedback.

- Refine: Make necessary design and engineering adjustments based on the analysis.

This cycle continues until the product meets all performance, quality, and user experience requirements. For example, if initial noise tests on an air purifier prototype reveal higher-than-desired decibel levels, the engineering team, in collaboration with the manufacturing partner, would refine the fan design, motor housing, or internal baffling to reduce noise, then build and test a new prototype. HisoAir’s Decibel Cancellation™ Technology is a testament to years of such iterative refinement.

By embracing this iterative prototyping and testing process, you significantly reduce the risks associated with mass production and increase the likelihood of launching a high-quality, market-ready product that truly resonates with your target audience.

Step 6: Planning the Production of Your New Product – Orchestrating Efficiency

With a refined product design and a strong manufacturing partnership in place, the focus shifts to meticulous production planning. This phase is about translating the product’s complete definition into a detailed roadmap for manufacturing, ensuring efficiency, quality, and timely delivery. It’s a complex undertaking that involves various specialists, from production planners to quality engineers and supply chain experts.

The Blueprint for Manufacturing

Production planning involves several critical components:

- Supply Chain Mapping: This entails identifying and mapping out every component and raw material required for your product, from the smallest sensor to the largest housing part. It includes identifying suppliers, establishing procurement processes, and managing logistics to ensure a steady and timely flow of materials. For IAQ products, this could mean sourcing specialized filters, precise sensors, and efficient motors from various global suppliers.

- Manufacturing Process Definition: Every step of the manufacturing process is laid out in detail. This includes assembly line configurations, specific machinery required, quality control checkpoints at each stage, and standard operating procedures for workers. For example, the assembly of an air purifier would involve precise steps for integrating the fan, motor, filter housing, and electronic controls, followed by calibration and testing.

- Tooling and Fixture Design: Custom tools, molds, and fixtures are often required for mass production. For instance, injection molds for plastic casings or specialized jigs for precise component assembly. Planning for the design, ordering, and production of these tools is crucial and often has long lead times.

- Quality Management System: A robust quality system is put into place to ensure consistent product quality. This includes defining quality standards, implementing inspection protocols (e.g., incoming material inspection, in-process checks, final product testing), and establishing procedures for handling non-conforming products. HisoAir’s CNAS-accredited lab and stringent testing capabilities are integral to this aspect, ensuring every unit meets international standards before leaving the factory.

- Logistics and Distribution: Planning how the finished products will be stored, packaged, and shipped to your target markets. This involves considerations for warehousing, transportation, and customs clearance for international distribution.

The Role of Lean Manufacturing Principles

Integrating lean manufacturing principles into your production planning can significantly optimize the process. Lean methodologies focus on minimizing waste, improving efficiency, and continuously enhancing the production flow. This means identifying and eliminating non-value-added activities, reducing lead times, and ensuring that every step contributes directly to the final product’s quality and value.

Effective production planning is the backbone of successful product launch and sustained market presence. It transforms your engineered design into a scalable, repeatable manufacturing operation, ensuring that your innovative indoor air quality product can be delivered to customers efficiently and reliably.

Step 7: Manufacturing Your New Product – Bringing Your Vision to Life

After meticulous planning, the moment arrives to commence the actual manufacturing of your new product. While this marks a significant milestone, it’s crucial to understand that the manufacturing phase is not merely the end of the development journey but an ongoing, iterative process that requires continuous oversight and refinement. For indoor air quality products, ensuring consistent quality and performance during mass production is paramount to market success and brand reputation.

The Production Launch: From Blueprint to Reality

Manufacturing involves the coordinated execution of all the plans laid out in the previous stages. This includes:

- Component Sourcing and Procurement: Ensuring all raw materials and components are delivered on time and meet specified quality standards. This is where strong relationships with suppliers and robust supply chain management, often facilitated by experienced OEM/ODM partners like HisoAir, prove invaluable.

- Assembly and Production: The physical assembly of your product, following the detailed manufacturing processes defined. This can range from automated assembly lines to manual workstations, depending on the product’s complexity and production volume. For IAQ devices, this involves the precise integration of mechanical, electrical, and filtration components.

- Quality Control and Testing: Throughout the manufacturing process, rigorous quality control checks are performed at various stages. This includes in-line inspections, functional testing of sub-assemblies, and comprehensive final product testing. HisoAir’s commitment to strict quality control, including CADR performance, noise level, and durability assessments in their CNAS-accredited laboratory, exemplifies the level of scrutiny required to ensure every unit meets the highest standards.

- Packaging and Labeling: Preparing the finished products for shipment, including packaging that protects the product during transit and clearly communicates brand information, product features, and compliance details.

Continuous Improvement in Manufacturing

Manufacturing is not a static process; it’s an opportunity for continuous improvement. Adopting methodologies like lean manufacturing is essential to identify and eliminate waste, optimize workflows, and enhance overall efficiency. This involves regularly analyzing production data, identifying bottlenecks, and implementing corrective actions to streamline operations and reduce costs without compromising quality.

Key areas for continuous improvement in IAQ product manufacturing include:

- Yield Optimization: Maximizing the number of defect-free units produced, thereby reducing waste and improving profitability.

- Process Efficiency: Streamlining assembly steps, reducing cycle times, and optimizing resource utilization.

- Quality Assurance: Continuously monitoring product quality, addressing any deviations promptly, and implementing preventive measures to avoid future issues. This includes tracking performance metrics like sensor accuracy, noise levels, and filter efficiency in manufactured units.

- Cost Reduction: Identifying opportunities to reduce manufacturing costs through process improvements, material optimization, or negotiation with suppliers.

Your role, even during the manufacturing phase, is to oversee this dynamic process, ensuring that all stakeholders are accountable for meeting the established cost, schedule, and quality goals. A strong partnership with a manufacturer like HisoAir, with their proven performance and premium quality promise, ensures that your innovative indoor air quality product is not only produced efficiently but also consistently meets the high standards your customers expect.

Conclusion: Your Path to Product Success in the IAQ Market

Transforming an innovative idea into a market-ready product is a journey that demands meticulous planning, strategic execution, and unwavering commitment. In the dynamic indoor air quality (IAQ) sector, where technological advancements and consumer expectations are constantly evolving, a structured approach is not just beneficial—it’s essential for success. This 2025 guide has outlined the critical steps, from initial concept validation and market research to detailed engineering, manufacturing partnerships, and continuous production refinement.

For businesses and entrepreneurs venturing into 공기 청정기, 가습기, diffusers, or dehumidifiers, the path to product realization is paved with opportunities for innovation. By focusing on genuine customer needs, embracing iterative design and testing, and forging strong alliances with experienced OEM/ODM manufacturers like HisoAir, you can significantly enhance your chances of bringing a high-quality, impactful product to market.

HisoAir, with its two decades of expertise in indoor air quality solutions, rigorous quality control, CNAS-accredited laboratories, and advanced technologies like Decibel Cancellation™ and Smart Connectivity, stands as a testament to what can be achieved with a dedicated and knowledgeable partner. Their global manufacturing capabilities and commitment to international standards provide a robust foundation for any aspiring product developer.

Remember, the journey from idea to product is a marathon, not a sprint. It requires patience, adaptability, and a willingness to learn and iterate. By following these steps and leveraging the right partnerships, your vision for a cleaner, healthier indoor environment can indeed become a tangible reality, making a significant impact in the lives of your customers and securing your place in the future of the IAQ market.