Your D2C brand launches a new humidifier, but 1-star reviews pour in about mold and noise. The solution isn't more features; it's smarter engineering from the very first component.

The secret is combining material science1 with acoustic design. Using a dense, non-porous material like stainless steel prevents mold growth while its inherent mass dampens sound, solving the two biggest customer complaints with a single, elegant engineering choice.

In my years in the mold and manufacturing business, I've seen too many promising products fail. A great design on paper becomes a nightmare for customers. Why? Because the brand chose a factory that just assembled parts, not an engineering partner that solved problems. They focused on the unit price and ignored the hidden costs of a bad reputation.

This is a de-risking post. I'm going to show you, as a designer, how to avoid these pitfalls. We'll look at the two biggest failure points of cheap humidifiers and how to engineer solutions from the ground up. This is how you build a product that earns 5-star reviews and a loyal following. Let's dive in.

All humidifiers will eventually grow mold, regardless of the material.False

While all humidifiers require cleaning, non-porous materials like stainless steel are highly resistant to mold colonization, unlike porous plastics where biofilm can easily take root.

Cheap humidifiers often receive negative reviews related to noise and hygiene issues.True

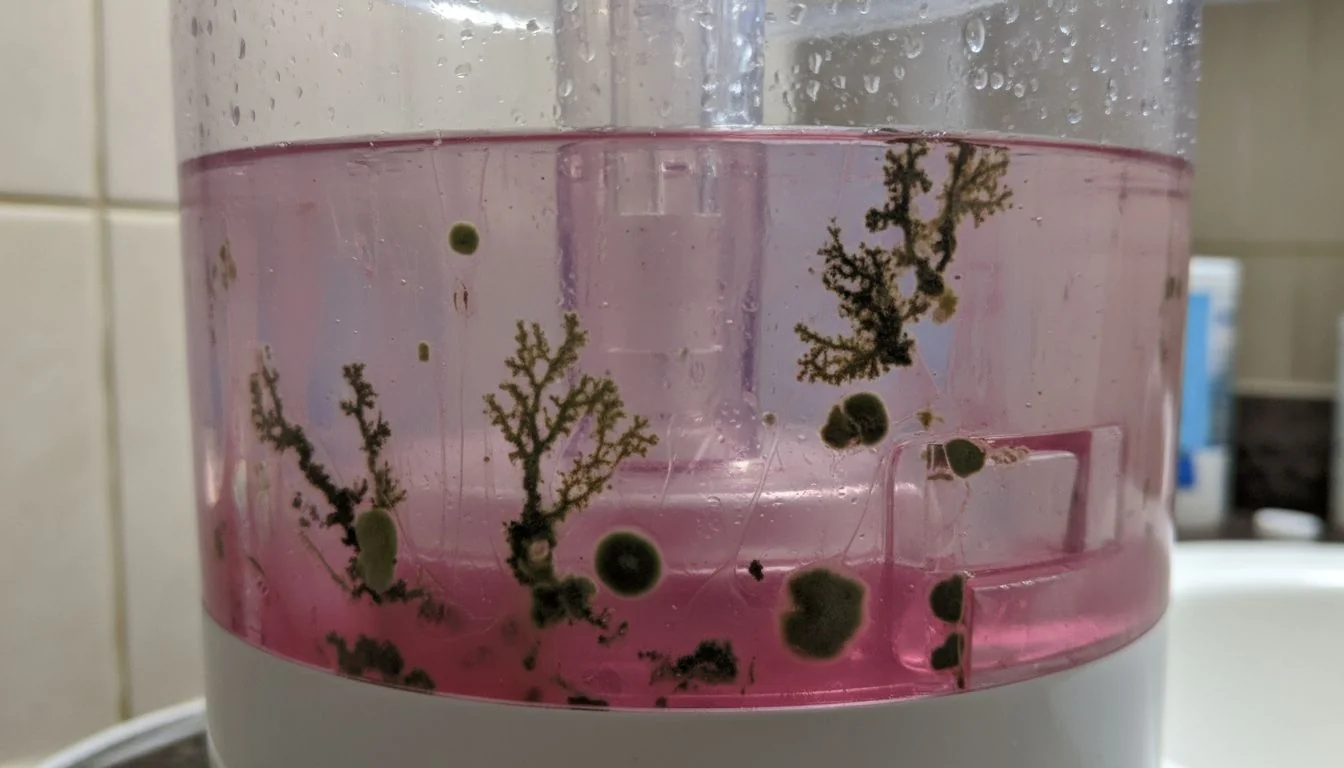

A quick search of customer reviews for low-cost humidifiers frequently reveals complaints about loud operation, rattling, and difficulty cleaning, which often leads to mold or 'pink slime' buildup.

Why Do So Many Humidifiers End Up with Mold and Noise Complaints?

You've perfected the CAD model for a beautiful humidifier. But the first prototype from the factory is already growing slime and sounds like a cheap fan. This is a common story.

These products fail because they are built with porous plastics and thin, vibrating parts. These aren't separate issues. They are symptoms of one root problem: prioritizing a low bill of materials over sound engineering principles. This choice inevitably leads to customer dissatisfaction.

The Two Core Failures

As a designer, you know that a product is a system. When one part is compromised for cost, the whole system suffers. In cheap humidifiers, the failures are almost always traced back to the material and mechanical assembly. The plastic chosen for the water tank is often porous, creating a perfect breeding ground for bacteria. At the same time, the thin plastic housing acts like a drum, amplifying every vibration from the motor and fan. The result is a product that is both unhygienic and annoying to use. It's a recipe for 1-star reviews that blame your design, when the real culprit was the manufacturing compromise.

| 기능 | Cheap Plastic Humidifier | Engineered Steel Humidifier |

|---|---|---|

| Water Tank Material | Porous ABS or PP Plastic | Non-Porous SUS304 stainless steel2 |

| Surface Property | Microscopic crevices harbor bacteria | Smooth, inert surface resists biofilm3 |

| Acoustic Property | Thin walls resonate and amplify noise | Dense material dampens vibration |

| Common Complaint | "It's slimy and loud." | "It's clean and quiet." |

The noise level of a humidifier is determined solely by the quality of its fan.False

While the fan is a source of noise, the housing material, motor isolation, and airflow design are equally, if not more, important. A thin plastic case can amplify a quiet fan's noise.

Biofilm, often seen as 'pink slime,' can form on the surfaces of humidifiers, especially those made from plastic.True

The bacteria Serratia marcescens is a common culprit for the pinkish biofilm found in damp environments like showers and humidifiers. Porous plastic surfaces can make it harder to clean away completely.

How Can Material Choice Make a Humidifier Truly Mold-Free?

You're tired of specifying "anti-bacterial" plastics that don't really work. This leads to customer complaints4 about mold and slime, forcing costly returns and damaging the brand's credibility. The real solution is choosing a material that is inherently inhospitable to microbial growth.

A truly mold-resistant design relies on non-porous materials. Stainless steel, specifically grade SUS304, offers a smooth, inert surface. Bacteria and mold cannot easily attach and colonize, ensuring long-term hygiene without chemical coatings that can wear off over time.

Beyond "Anti-Bacterial" Coatings

Many factories will offer to add an "anti-bacterial" coating or additive to their plastic parts. In my experience, this is a temporary fix, not a real solution. These coatings can wear off with cleaning or degrade over time. More importantly, they don't solve the fundamental problem: the porosity of the plastic itself. Microscopic pits and cracks in the plastic surface still trap water and provide a safe harbor for biofilm to grow.

I once worked with a client who was skeptical about the added cost of a stainless steel tank. We ran a simple test. We filled their chosen plastic prototype and our steel prototype with water and let them sit for 30 days. When they returned, the plastic tank had a visible layer of slime. The steel tank was still pristine. The visual evidence was undeniable. They understood immediately that the steel wasn't a "feature"; it was a core part of the product's value and a way to protect their brand. That's the power of starting with the right material science.

Stainless steel is completely immune to all forms of bacteria and never needs to be cleaned.False

While highly resistant to bacterial colonization, no surface is 100% maintenance-free. Stainless steel is easy to clean and sanitize effectively, but it still requires regular cleaning to remain hygienic.

SUS304 stainless steel is widely used in food processing and medical applications because of its corrosion resistance and hygienic properties.True

This grade of steel is chosen for these industries because it is non-porous, does not leach chemicals, resists corrosion from cleaning agents, and can be thoroughly sanitized.

What's the Secret to Designing a Genuinely Quiet Humidifier?

The spec sheet says "whisper-quiet," but the product buzzes and rattles. This gap between marketing and reality destroys user trust and generates negative reviews. True quietness comes from a systems-based approach to acoustic design5, focusing on dampening, isolation, and airflow.

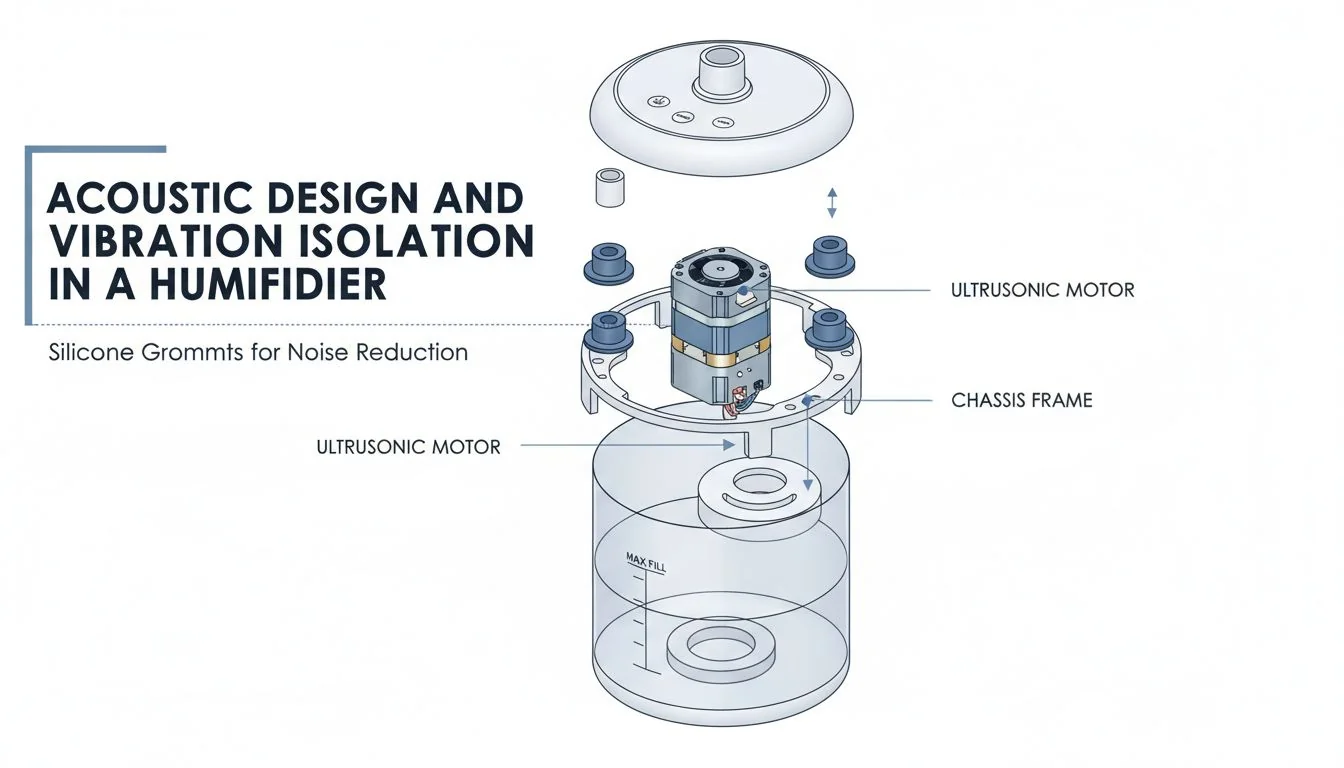

The secret to a quiet humidifier is not just a better fan. It is about comprehensive acoustic engineering6. This means isolating the motor's vibration, optimizing airflow to reduce turbulence, and using materials with high mass to dampen, not amplify, sound waves.

A System for Silence

A quiet product is the result of deliberate engineering choices, not luck. There are three key areas we focus on.

- Isolating the Source: The motor and fan are the primary sources of vibration. Instead of mounting them directly to the housing, we use soft silicone or rubber grommets. These act as shock absorbers, preventing the vibrations from transferring to the larger structure and turning it into a speaker.

- Optimizing Airflow: A lot of noise isn't from the motor, but from the air itself. Turbulent airflow creates a "whooshing" sound. We use computational fluid dynamics (CFD) simulations to design the internal pathways and vents. The goal is to create a smooth, laminar flow of air, which is much quieter.

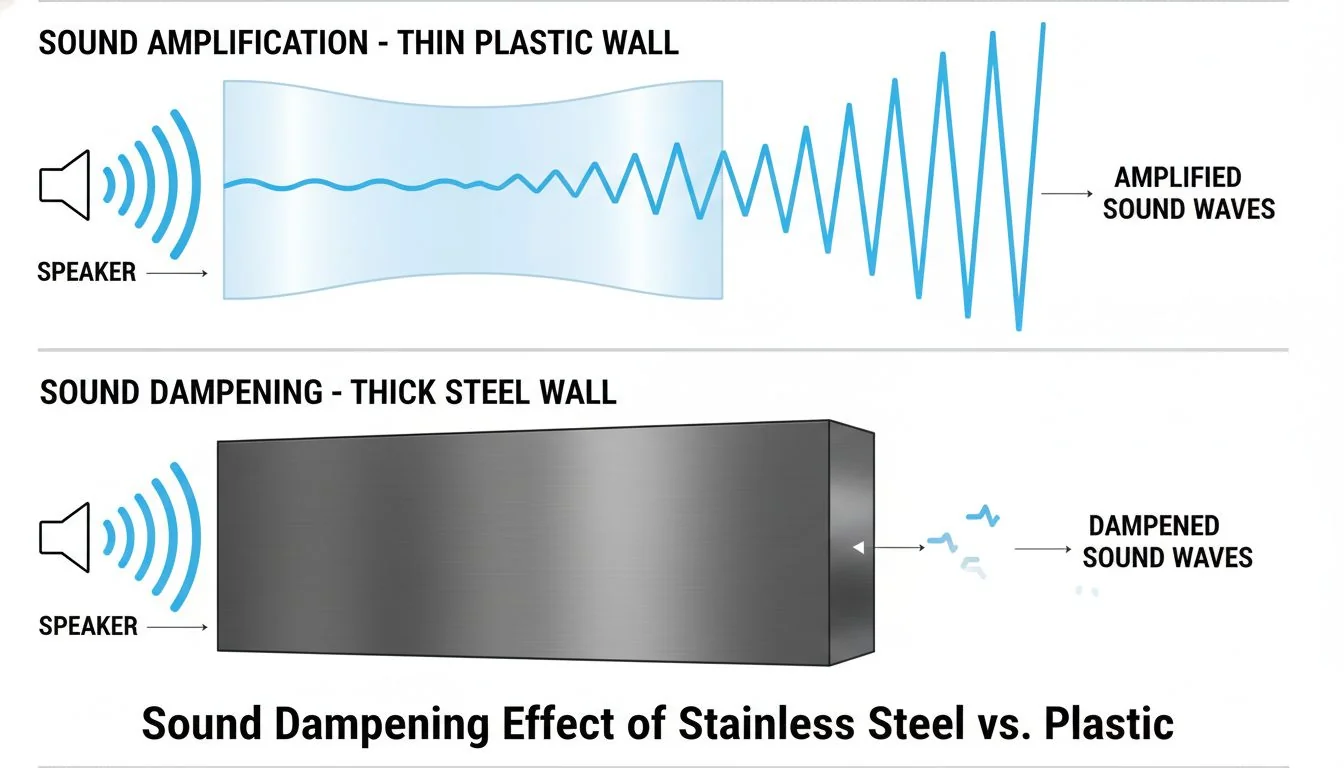

- Dampening with the Enclosure: The product's housing is the final piece of the acoustic puzzle. A thin, lightweight plastic shell will vibrate easily and radiate sound. A heavier, more rigid enclosure will resist vibration and dampen sound. This is where material choice becomes critical for acoustics, not just hygiene.

Placing a piece of foam inside a product will make it silent.False

While acoustic foam can absorb some high-frequency, airborne sound, it does little to stop structure-borne vibration, which is a major source of noise in motorized products. Isolation and damping are more effective.

Vibration isolation using elastomeric materials like rubber is a fundamental technique in mechanical and acoustic engineering to reduce noise.True

This principle, known as impedance mismatch, is used in everything from engine mounts in cars to building foundations to prevent the transmission of vibrational energy from a source to a radiating structure.

How Can a Single Material Choice Solve Both Mold and Noise Problems?

You are constantly making trade-offs in design. A hygienic material is expensive. A quiet design is complex to assemble. This forces compromises that result in a mediocre product. But the most elegant engineering solutions solve multiple problems with a single, strategic choice.

The key is using a dense, solid material like stainless steel. Its non-porous surface prevents mold. At the same time, its mass and rigidity dampen vibrations from the motor. Thin plastic, in contrast, acts like a drum skin and amplifies these same vibrations.

The Unified Engineering Advantage

This is where we move beyond a simple checklist of features and into a holistic design philosophy. This is the "Hisoair Advantage" I talk about with my clients. We don't see "hygiene" and "acoustics" as separate problems to be solved. We see them as an interconnected system.

The physics are simple. In acoustics, there's a principle called "mass law." It states that heavier, more rigid materials are better at blocking sound. A thin plastic wall is easy to vibrate, so it readily transmits and radiates sound energy into the room. A solid stainless steel wall is much harder to move. It resists vibration and effectively dampens the sound energy, converting it into imperceptible amounts of heat. By choosing stainless steel for its hygienic properties, we get this powerful acoustic benefit for free. This is how one smart decision at the material science level can elevate the entire product experience.

| Property | Thin Plastic Housing | Stainless Steel Housing |

|---|---|---|

| Hygienic Performance | Porous, hard to clean | Non-porous, easy to sanitize |

| Acoustic Mass | 낮음 | 높음 |

| Vibration Response | Resonates and amplifies | Dampens and absorbs |

| Resulting Benefit | 없음 | Hygiene + Quietness |

Thin plastic is an excellent material for soundproofing.False

Thin, lightweight, and rigid materials like many plastics are actually very poor at soundproofing. They vibrate easily and are efficient at radiating sound, often amplifying it through resonance.

According to the principles of acoustics, materials with higher mass and stiffness generally provide better sound insulation (transmission loss).True

This is known as mass law. Doubling the mass/density of a barrier can improve its sound insulation by up to 6 decibels, making heavy materials like steel, concrete, or dense composites effective at blocking sound.

How Does Partnering with an R&D-Focused Manufacturer De-Risk Your Product Launch?

Launching a new product feels like a gamble. You worry about technical failures, bad reviews, and compliance issues. A failed launch can hurt a D2C startup and damage your professional reputation. You can de-risk this process by partnering with a manufacturer who has already solved the core engineering challenges.

This means you are not just buying a "gadget." You are co-developing on a proven, pre-validated platform. This eliminates the biggest technical risks—hygiene and noise—and ensures compliance. It allows your brand to focus on marketing and growth instead of firefighting technical problems.

Buying a Platform, Not Just a Product

I encourage my clients to think of us as their external R&D lab, not just a factory. A factory takes your drawings and builds them as cheaply as possible. An engineering partner collaborates with you to build the product right. We bring our own research, testing, and solutions to the table.

A product like the Hisoair humidifier is a perfect example. The core platform is already engineered. The material science, the acoustic design, the motor selection, the power supply, and the safety certifications (like ETL) are already done. This is a proven, de-risked foundation. The D2C brand can then come in and focus on what they do best: designing a beautiful outer shell, creating a unique user interface, developing smart-home connectivity, and building a powerful brand story. This approach is faster, safer, and ultimately more profitable than trying to reinvent the wheel from scratch with a low-cost assembler. It's about building on a foundation of proven engineering.

The cheapest manufacturer always provides the best value for a new D2C brand.False

The initial low unit cost can be quickly erased by the high costs of product returns, negative reviews, reputational damage, and potential redesigns, making it a false economy.

Using a pre-certified product platform or core components can significantly reduce a product's time-to-market and compliance costs.True

Leveraging existing certifications for components like power supplies or entire internal systems means the new product may only need partial or simpler testing, saving months of time and tens of thousands of dollars in lab fees.

결론

The best products are not just assembled; they are engineered. Success comes from partnering with manufacturers who solve core problems like hygiene and noise before production even begins. Stop buying gadgets. Start co-developing a solution.

References

-

Understanding material science is crucial for creating innovative products that solve real-world problems. ↩

-

Stainless steel offers durability and hygiene, making it a preferred choice in many applications. ↩

-

Understanding biofilm is essential for designing products that remain hygienic and safe for users. ↩

-

Identifying customer complaints helps manufacturers improve product design and customer satisfaction. ↩

-

Acoustic design is essential for reducing noise and enhancing user experience in various products. ↩

-

Acoustic engineering is crucial for creating quiet and efficient products that meet user expectations. ↩