You have a sleek design and a compelling brand story, but your prototype keeps failing. Why do so many hardware startups crumble while marketing-led brands seem to thrive?

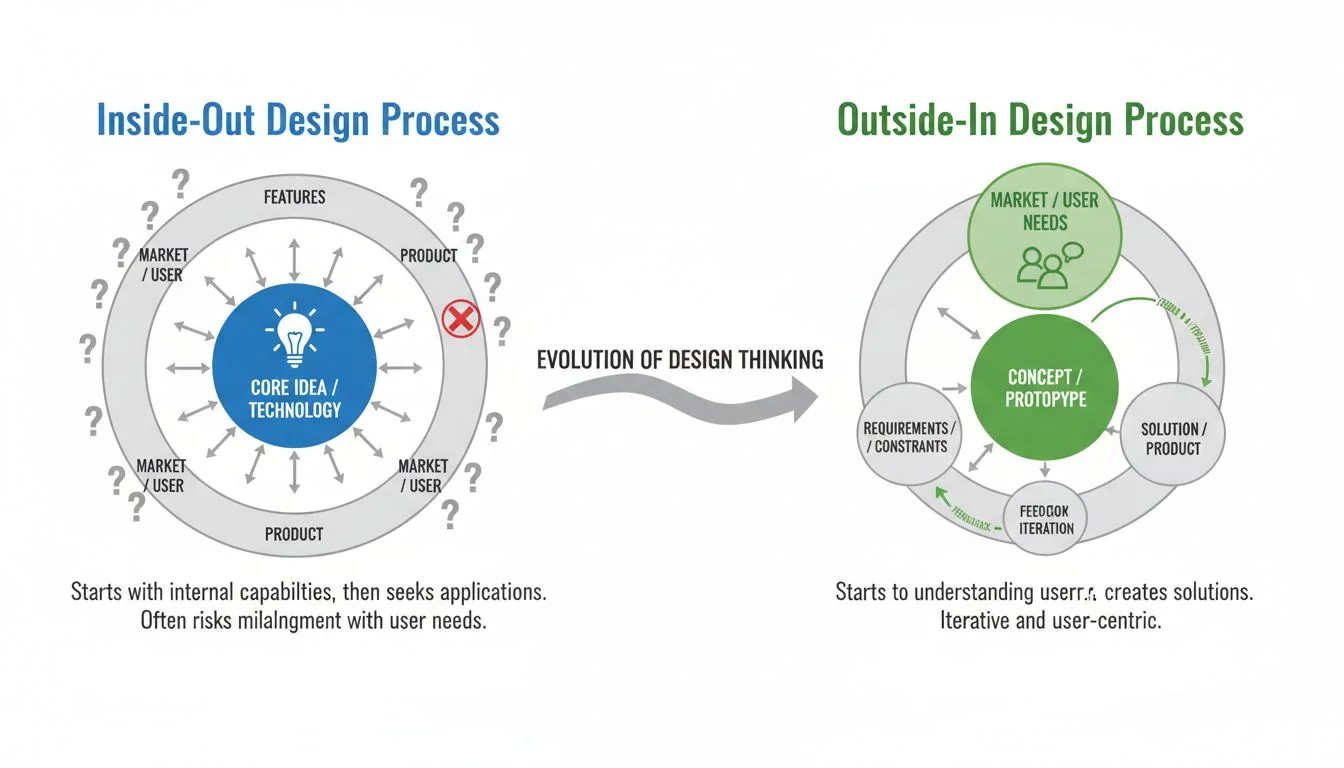

D2C brands fail when they prioritize aesthetics over hygiene and ignore the "Inside-Out" design philosophy. Success requires starting with food-grade materials1 and certified internal components before designing the outer shell. This prevents costly compliance delays and ensures your wellness brand actually delivers safe water.

I have seen too many talented designers like you hit a wall. You focus on the curve of the casing, but the real danger is inside. Let’s look at the specific mistakes that kill projects.

Marketing can save a product with poor internal engineering.False

No amount of marketing can fix a product that leaks or fails safety certifications.

Designing the exterior before the internal water routing leads to failure.True

This 'Outside-In' approach forces engineers to compromise on hygiene and safety to fit components into a shell.

Is Marketing Really More Important Than Engineering?

Founders often think a viral ad campaign guarantees success. But if the product cannot be manufactured reliably, the best marketing in the world is useless.

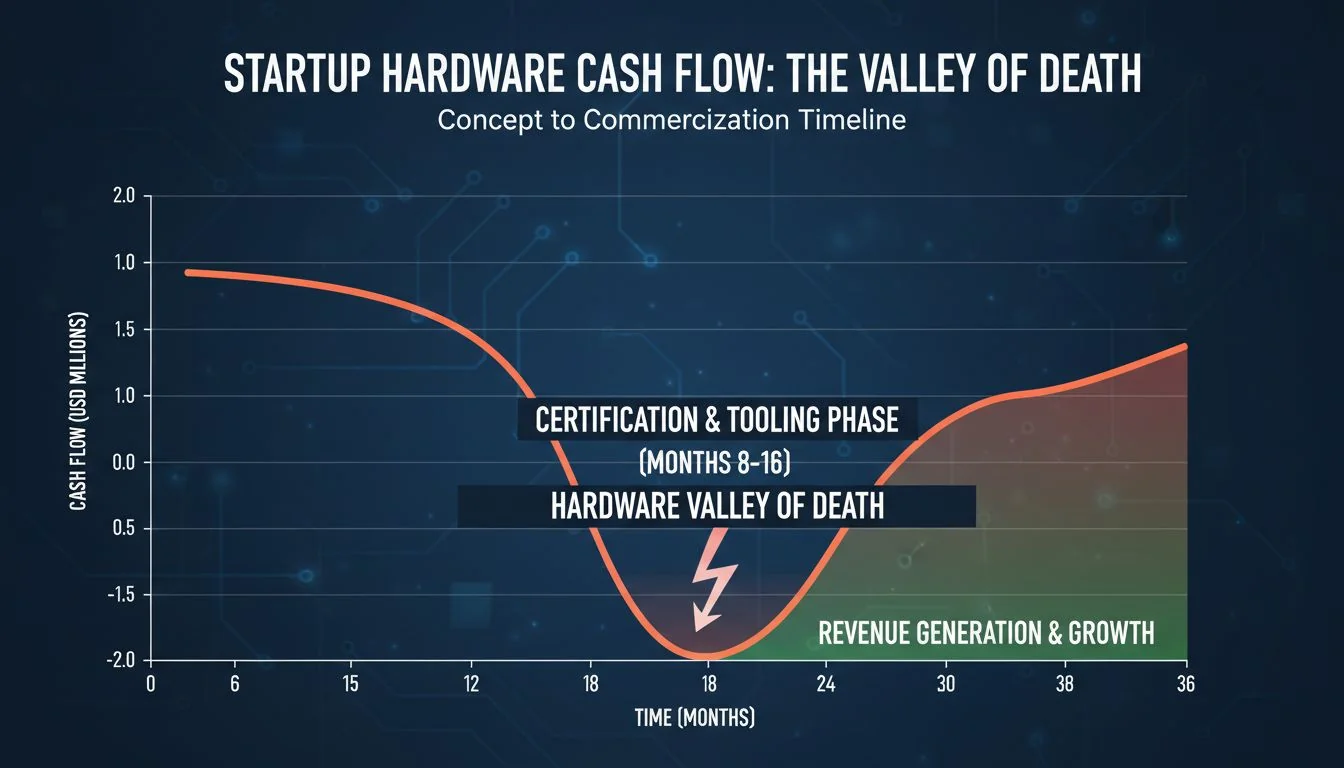

Hardware startups fail because they run out of cash waiting for a product that works. It is rarely a lack of demand; it is usually a failure to navigate the "Valley of Death2" between a prototype and a certified, mass-producible unit.

Many founders I meet come from a marketing background. They have a vision for a brand that looks like Apple but works like a Brita. They spend months perfecting the logo and the website. However, they treat the hardware as an afterthought. This is the first major error.

In the mold industry, we see the reality that renders hide. A 3D render does not leak. A 3D render does not grow mold. But a physical product does. When you prioritize marketing over engineering, you create a "time bomb." You might get pre-orders, but you cannot ship.

The Reality of Hardware

- Cash Burn: You burn cash every day your product is stuck in the factory.

- Reputation: If you ship a product that leaks, your brand dies instantly.

- Complexity: Water is difficult. It finds every weak point in your mold design.

You need to shift your mindset. You are not just building a brand; you are managing a complex manufacturing project. The engineering must lead the marketing, not the other way around.

Most hardware startups fail due to lack of market demand.False

Most fail due to technical execution, certification delays, and running out of cash before shipping.

Renders often hide manufacturing realities like draft angles and sealing issues.True

Digital designs do not account for physical constraints like water pressure or mold shrinkage unless engineered correctly.

Are You Prioritizing Aesthetics Over Hygiene?

You want your product to look amazing on a countertop. But if you design the shell first, you are building a trap for yourself.

The "Skin-Deep" trap occurs when designers finalize the exterior look before solving internal water routing3. This forces engineers to cram components into tight spaces, leading to stagnant water, bacterial growth, and impossible mold tooling requirements.

This is where I see the "Outside-In" mindset cause the most damage. You design a beautiful, slim casing. Then, you hand it to an engineer and say, "Fit the pumps, filters, and tubes inside this."

This is a disaster for water appliances. When you force components into a pre-defined shell, you create "dead zones." These are sharp corners in the tubing or tanks where water stops moving. Stagnant water grows bacteria.

The "Inside-Out" Philosophy

Great brands design Inside-Out. You must follow this order:

- Material: Choose food-grade, safe materials.

- Function: Layout the water path to ensure flow and prevent leaks.

- Aesthetic: Wrap the beautiful shell around the functional core.

As a mold expert, I can tell you that "Outside-In" designs are a nightmare to tool. They often require complex sliders and lifters to handle the internal geometry, which increases your mold costs4 and cycle time. By designing Inside-Out, you ensure the product is safe, hygienic, and manufacturable.

Designing the shell first simplifies the engineering process.False

It complicates engineering by forcing components into unnatural spaces, increasing failure risk.

Stagnant water in an appliance leads to bacterial growth.True

Dead zones in water routing allow bacteria to multiply, compromising user safety.

Is Your Wellness Brand Built on a Plastic Core?

Your brand promises health and purity. Yet, to save money, you might be using cheap internal tubing. This is a fatal contradiction.

Launching a premium wellness brand with non-food-grade plastic internals is a "Brand Contradiction5." Customers pay for purity, but cheap plastics leach chemicals. This destroys brand integrity and leads to high return rates once customers taste the difference.

I call this the "Brand Contradiction Hammer." It is the most emotional mistake you can make. Imagine you are selling a $500 water purifier. Your website talks about "wellness," "detox," and "pure hydration."

But inside the machine, you use cheap PVC tubing or low-grade plastic tanks to save $5 per unit. This is a lie to your customer.

Don't Let Your Hardware Lie

Water is a universal solvent. It absorbs everything it touches. If it sits in cheap plastic, it tastes like plastic.

- The Taste Test: Customers will taste the "plastic funk" immediately.

- The Trust Factor: Once they open the unit and see cheap materials, they feel cheated.

- The Solution: You must use materials like high-grade stainless steel or certified food-grade polymers.

From a mold perspective, high-grade materials shrink and warp differently than cheap plastics. You must decide on the material before you cut the steel for the mold. You cannot switch from cheap plastic to high-grade material later without ruining your tooling.

Customers cannot taste the difference between cheap plastic and food-grade materials.False

Water absorbs flavors from cheap plastics, leading to a distinct, unpleasant taste.

Using cheap internals in a premium product destroys brand trust.True

It creates a contradiction between the brand promise of health and the reality of the product.

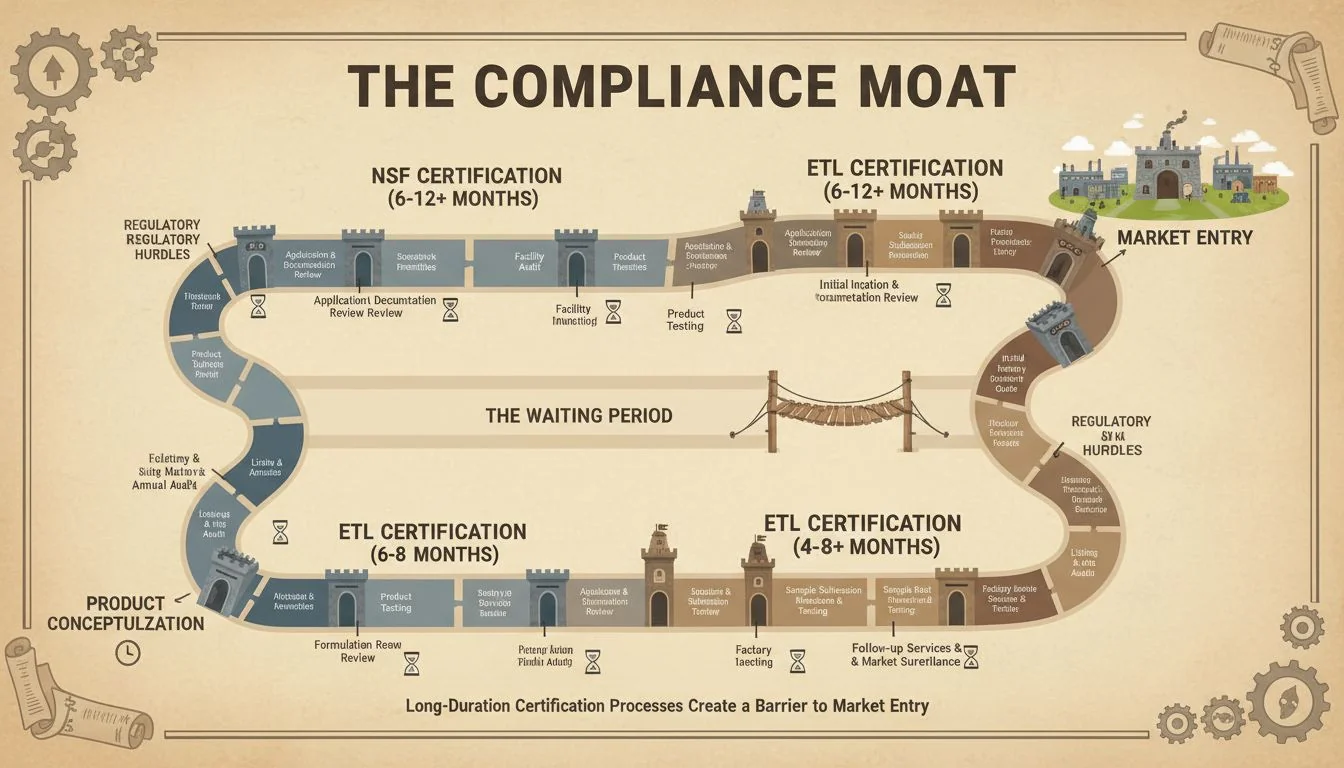

Do You Underestimate the NSF and ETL Compliance Moat?

You think certification is just paperwork at the end. In reality, it is a massive wall that stops product launches dead in their tracks.

Ignoring NSF and ETL standards until the end is a disaster. These certifications take months and cost thousands. If you fail, you must redesign molds and retool, which burns through your startup capital while you wait.

I have seen startups die while waiting for a piece of paper. In the water industry, you cannot sell without safety certifications like ETL (electrical safety) and NSF (water safety).

Many designers treat this as a final step. They finish the mold, make the product, and send it to the lab. Then the lab says, "This plastic is not approved," or "This electrical spacing is too tight."

The Cost of "Pre-Certified"

Now you are in trouble. You have to:

- Change the design.

- Modify or scrap your expensive molds.

- Wait another 3 to 6 months for a re-test.

This is why "Pre-Certified Platforms" are a survival strategy. Instead of building the engine from scratch, you use a core system that is already certified. You build your design around it. This is not a shortcut; it is a safety net. It lets you focus on marketing while ensuring the technology is legal and safe from day one.

Certifications like NSF and ETL can be done quickly at the end of the project.False

These certifications take months and often require design changes if not planned for early.

Using pre-certified components reduces time to market.True

It eliminates the risk of failing safety tests and avoids costly re-tooling.

Are You Trying to Reinvent the Wheel?

Designers love to create everything from scratch. But building a water filtration engine from zero is risky and unnecessary.

The "Reinvention Error" happens when brands try to engineer their own pumps and filters instead of using a proven platform. Smart brands use pre-engineered internal cores and focus their design efforts on the user interface and exterior housing.

There is a difference between being a "Pure OEM" (Original Equipment Manufacturer) and using a "Platform" approach.

- Pure OEM: You design every screw, pump, and tube. This is high risk. You are responsible for every leak.

- Platform: You take a proven internal engine (the water path, pump, and filter) and design your unique shell around it.

De-Risking Technology

As a mold expert, I advise my clients to de-risk. Why invent a new pump when reliable ones exist? Your value to the customer is not the pump; it is the user experience, the brand, and the convenience.

By using a platform, you leverage the engineering hours of experts who have already solved the leak problems. You get to market faster. You save money on mold costs because you only need to tool the exterior parts, not the complex internal manifolds. This allows you to invest more in high-quality exterior finishes that the customer actually sees and touches.

Designing every component from scratch adds value to the customer.False

Customers care about reliability and experience, not whether you designed the internal pump yourself.

Platform approaches lower mold costs and development risks.True

You avoid tooling complex internal parts and rely on proven engineering.

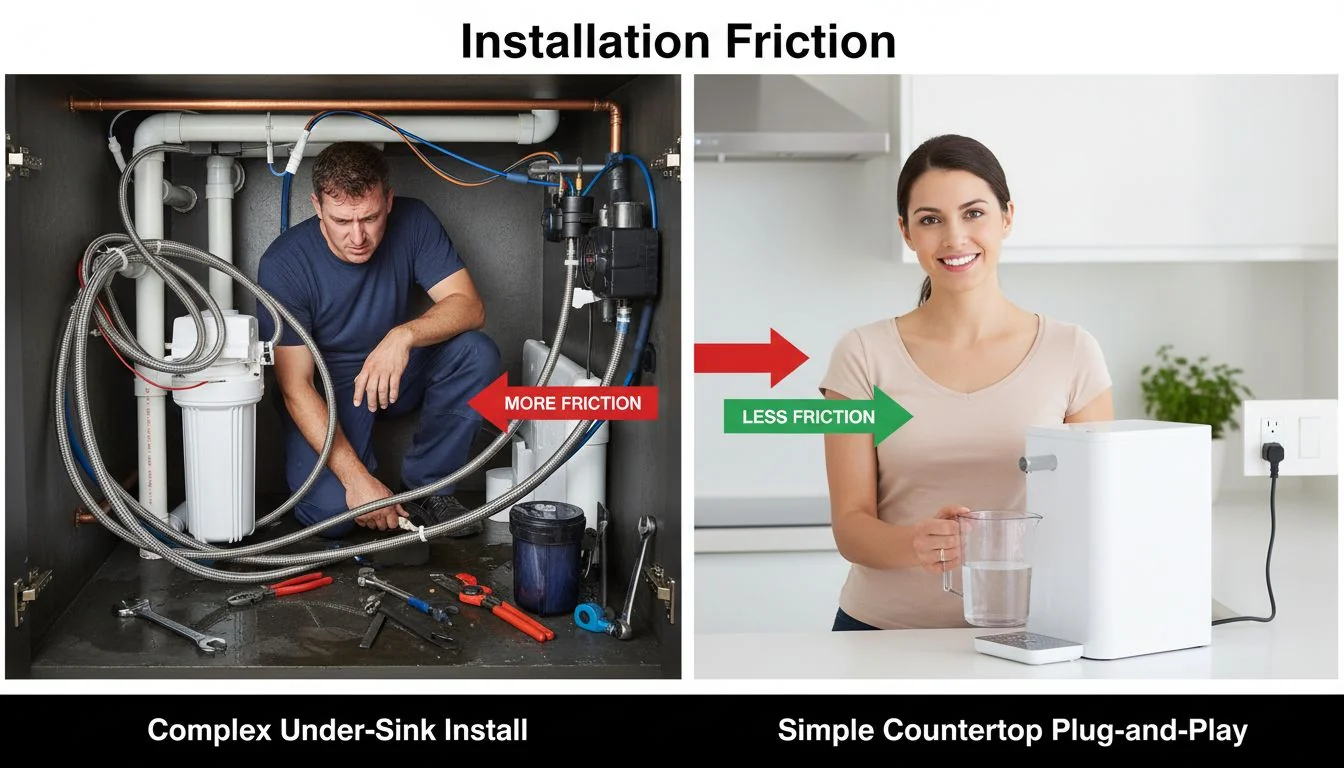

Are You Ignoring the Friction of Installation?

You want to sell under-sink systems because they look clean. But have you thought about how hard they are for a normal person to install?

Under-sink systems have high "Installation Friction6," requiring plumbers and drilling. This limits your market size. Countertop RO systems remove this friction, allowing for instant use, easier shipping, and significantly lower return rates for D2C brands.

"Friction" is the enemy of D2C sales. If a customer buys your product, they want to use it immediately.

The Under-Sink Trap

If you sell an under-sink system:

- The customer needs a plumber (extra cost).

- They need to drill a hole in their countertop (high commitment).

- If they rent their apartment, they cannot use it at all.

This creates a huge barrier to entry. It also leads to returns when customers realize the installation is too hard.

The Countertop Advantage

Countertop Reverse Osmosis (RO) systems have zero friction. You plug them in, fill the tank, and drink.

- Market Size: You can sell to renters, students, and homeowners.

- Logistics: They are compact and easier to ship.

- Returns: Lower return rates because there is no installation frustration.

From a design perspective, countertop units are fun. You can play with colors, textures, and interfaces because the unit sits on display. It becomes a piece of decor, not just a utility hidden in a dark cabinet.

Generate Claims

Under-sink systems are easy for the average customer to install.False

They often require plumbing skills, tools, and drilling, creating high friction.

Countertop systems have a larger addressable market than under-sink systems.True

They can be used by renters and do not require permanent installation.

Conclusion

To succeed in the water appliance market, you must design Inside-Out, prioritize hygiene over aesthetics, and reduce installation friction. Use pre-certified platforms to ensure safety and protect your brand integrity.

References

-

Exploring the significance of food-grade materials can enhance product safety and consumer trust. ↩

-

Learning about the Valley of Death can help startups navigate challenges between prototype and production. ↩

-

Exploring water routing can improve product functionality and safety in water appliances. ↩

-

Understanding mold costs can help manage budgets and improve manufacturing efficiency. ↩

-

Exploring Brand Contradiction can help maintain brand integrity and customer trust. ↩

-

Understanding Installation Friction can help design user-friendly products that enhance customer satisfaction. ↩