Choosing a humidifier technology1 feels overwhelming. But what if the real problem isn't the tech, but a hidden flaw shared by almost all manufacturers? Let's uncover the truth.

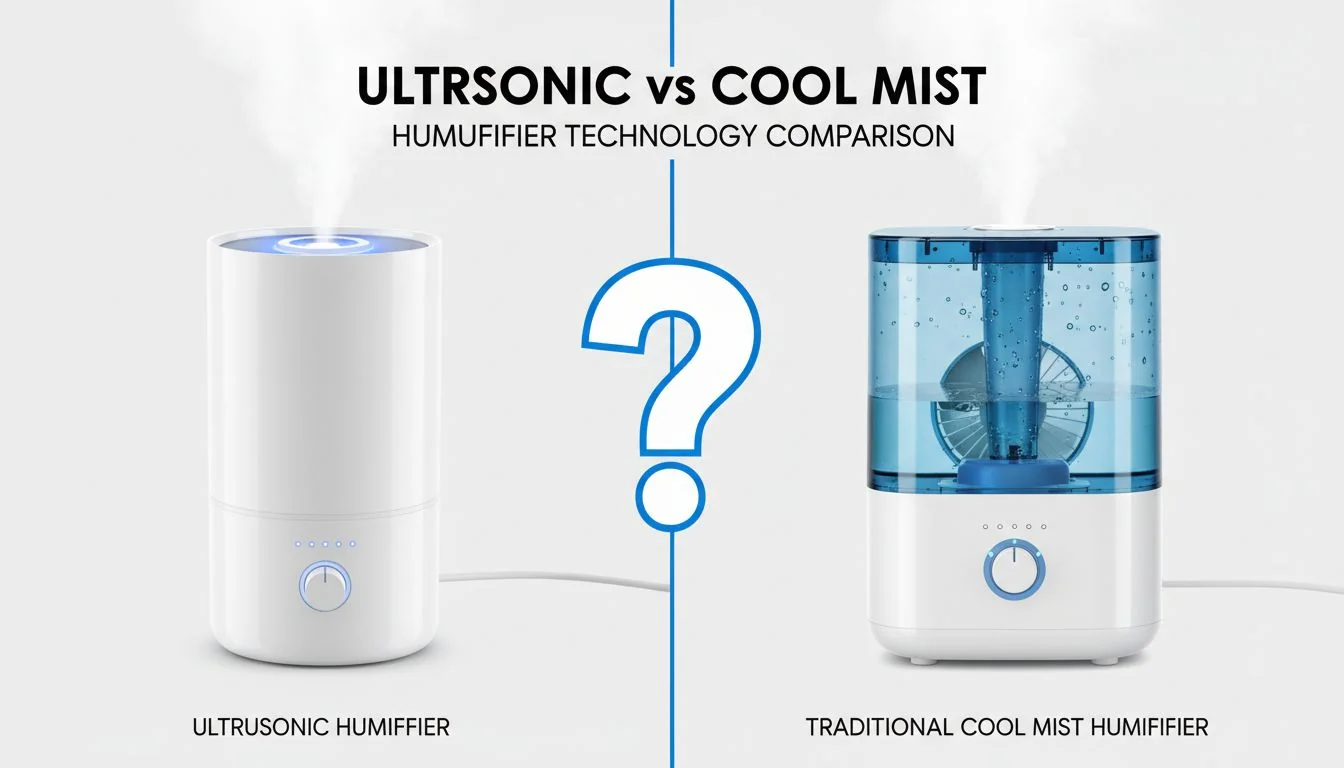

When comparing ultrasonic and cool mist humidifiers, ultrasonic uses high-frequency vibrations to create a fine mist, while other "cool mist" types, like evaporative, use a fan and wick. The key difference lies in the mist creation method, noise level, and maintenance requirements.

As someone who has spent a lifetime in manufacturing, I've seen countless product teams get stuck on the initial tech choice. They debate the merits of ultrasonic versus evaporative for weeks, thinking this is the most critical decision they'll make. I understand the impulse. You want to build the best product. But I've also seen this narrow focus lead directly to product failure. It's a classic case of winning a battle but losing the war.

The truth is, the debate between these technologies distracts from a much bigger, more dangerous problem. It’s a problem that affects almost every single humidifier on the market, regardless of how it makes mist. It’s a problem that lives in the 1-star reviews of even the most well-engineered products. Before we get to that, let's build some trust and answer the question you came here for.

Ultrasonic humidifiers can disperse fine white mineral dust into the air if used with hard tap water.True

The ultrasonic vibrations turn everything in the water, including minerals, into a fine mist. Using distilled water prevents this.

All cool mist humidifiers operate silently.False

Evaporative cool mist humidifiers use a fan to blow air across a wet wick, which generates noise. Ultrasonic humidifiers are generally much quieter.

How Do You Choose the Right Humidifier Technology?

You're designing a new humidifier and need to pick a technology. The choice seems critical, but what if you're focusing on the wrong details and risking product failure?

Choosing the right technology involves balancing performance, cost, and user experience. Ultrasonic offers quiet operation and a visible mist, while evaporative is self-regulating and avoids white dust2. Understanding these core differences is the first step for any product designer before committing to a manufacturing path.

The Designer's Dilemma: Tech Specs vs. User Reality

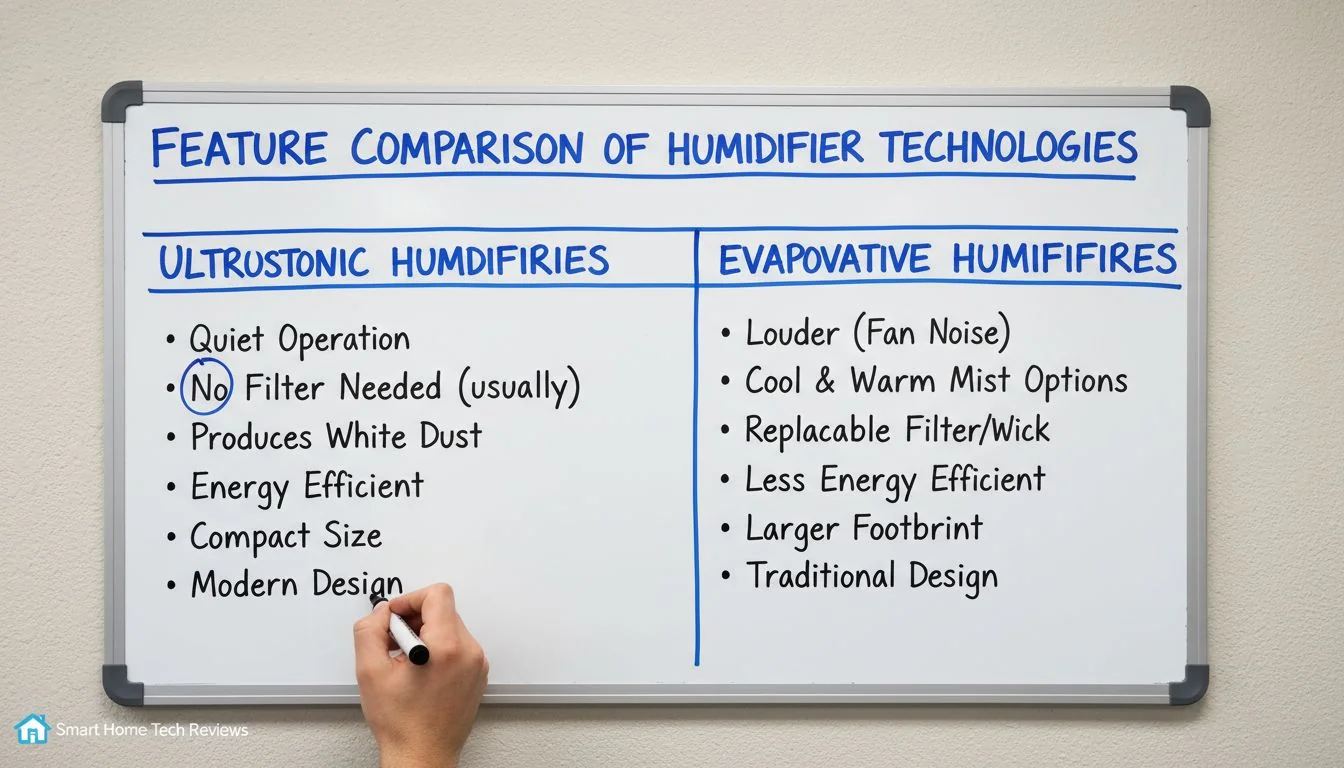

As a product designer, your world revolves around specs. I get it. I've worked with hundreds of designers like you, and the first thing we always do is lay out the technical trade-offs. For humidifiers, the main debate is usually between ultrasonic and evaporative technologies. Ultrasonic models are loved for being nearly silent and producing a visible, satisfying mist. However, they can create "white dust" from minerals in tap water. Evaporative models solve the white dust problem by trapping minerals in a wick, but they require a fan, which makes noise. They also need constant wick replacements, which is a hassle for the user and a recurring cost.

I've seen clients spend months agonizing over these points. They want the quiet of ultrasonic with the filter of evaporative. They get lost in the details, trying to engineer the perfect compromise. But they are missing the forest for the trees.

| Feature | Ultrasonic Humidifier | Evaporative Humidifier |

|---|---|---|

| Mechanism | High-frequency vibration | Fan and wick filter |

| Noise Level | Very Quiet | Noticeable Fan Noise |

| "White Dust" | Yes (with hard water) | No (minerals trapped in wick) |

| Filter | No (usually) | Yes (requires replacement) |

| Mist | Visible, fine mist | Invisible moisture |

Evaporative humidifiers use a wick filter to draw water up, which can trap minerals from the water.True

This is the core mechanism of evaporative technology, which prevents mineral dust but requires the filter to be cleaned or replaced regularly to prevent mold growth.

Ultrasonic humidifiers are always more energy-efficient than evaporative models.False

While often very efficient, the total energy consumption can vary greatly depending on the specific design, power output, and fan size (if any) of both types of humidifiers.

What Really Separates Ultrasonic from Other "Cool Mist" Humidifiers?

You see "ultrasonic" and "cool mist" on boxes, but what's the real difference for manufacturing? Misunderstanding this can lead to costly design flaws and unhappy customers. Let's clarify.

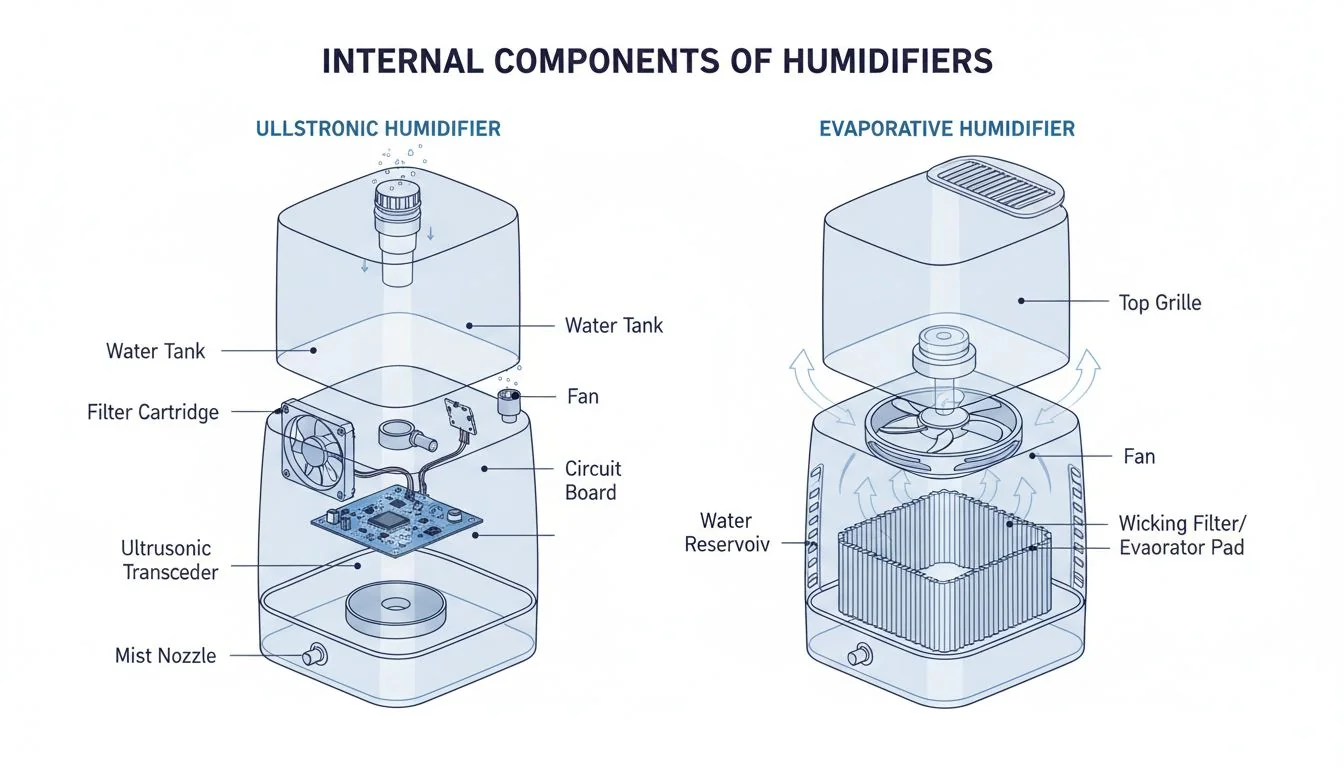

Ultrasonic technology uses a piezoelectric transducer vibrating at high frequencies to create a fine water mist. Other "cool mist" types, primarily evaporative, use a fan to blow air through a wet wick filter, causing water to evaporate. The core difference is mechanical (fan) vs. vibrational (transducer).

A Look Inside the Mold: Manufacturing Implications

From my perspective in mold design and manufacturing, the internal differences are significant. An ultrasonic humidifier is built around a small, sensitive electronic component: the piezoelectric transducer. The main challenge is designing a plastic housing that can hold this part securely, integrate with the power source, and, most importantly, create a perfect, leak-proof seal with the water tank. The nozzle design is also critical for directing the mist.

An evaporative humidifier is a more mechanical system. The key components are a large fan, a structure to hold the wick, and a large water reservoir. The design challenges here are more about airflow dynamics and creating a user-friendly way to access and replace the large, often clumsy, wick filter. But here is the key insight: despite their different engines, both of these designs almost always rely on one common element: a complex, injection-molded plastic water tank. And that is where the real problem begins.

| Component | Ultrasonic Manufacturing Focus | Evaporative Manufacturing Focus |

|---|---|---|

| Core Tech | Housing for transducer, sealing | Fan housing, airflow design |

| Water Path | Nozzle for mist direction | Structure for wick placement |

| Consumable | None (typically) | Wick filter (design for replacement) |

| Common Part | Plastic Water Tank | Plastic Water Tank |

Piezoelectric transducers are ceramic discs that change shape when a voltage is applied, creating ultrasonic vibrations.True

This is the fundamental principle behind ultrasonic technology, used not just in humidifiers but also in medical imaging and industrial cleaning.

Evaporative humidifiers can't over-humidify a room because the evaporation rate slows as relative humidity increases.True

This is a natural, self-regulating property of evaporation. As the air becomes more saturated with water, the rate of evaporation from the wick automatically decreases.

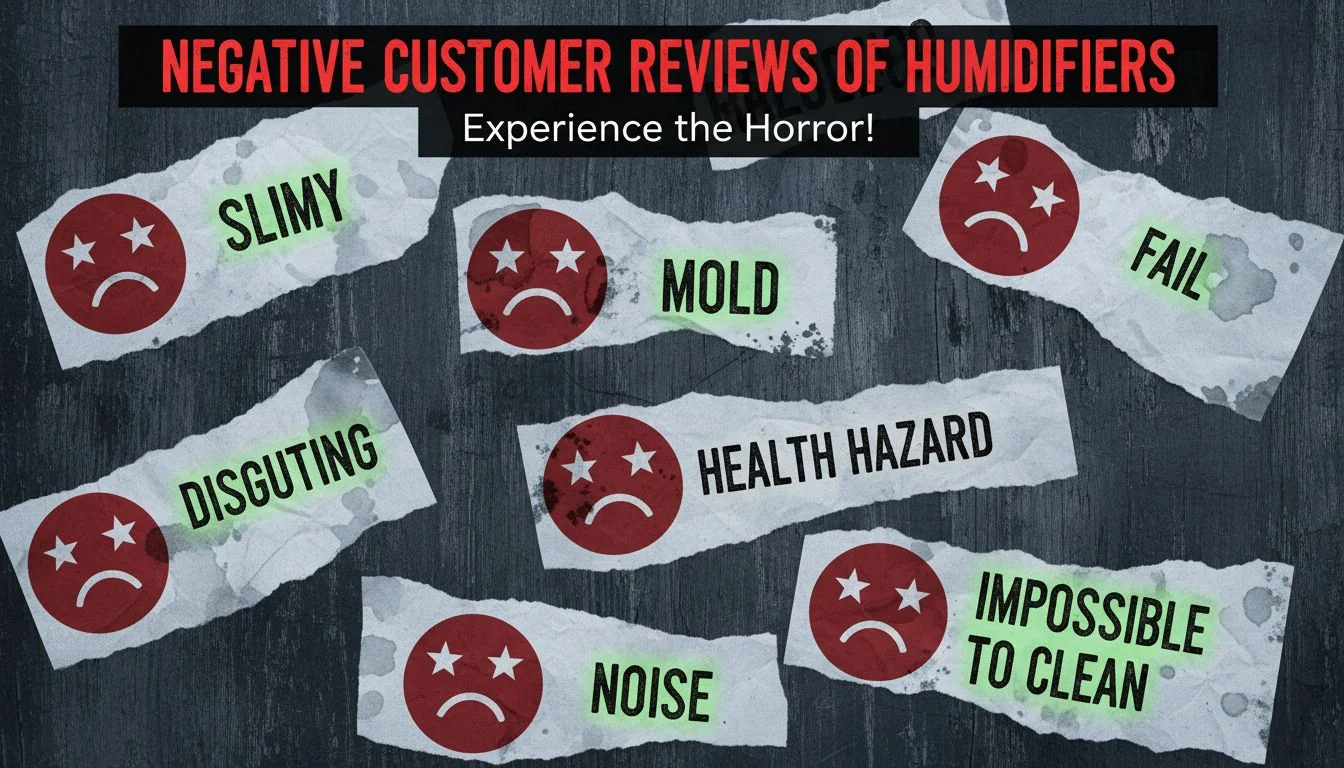

You've perfected the technology, but your product is getting 1-star reviews for being "slimy" and "impossible to clean." This common oversight is tanking brands. Here's the flaw.

The fatal flaw is the near-universal reliance on plastic for water tanks and internal components. Plastic surfaces, with their micro-pores and complex molded shapes, are breeding grounds for bacteria and mold3, leading to a constant, frustrating cleaning burden for the end-user and a flood of negative reviews.

From 5-Star Design to 1-Star Reality

This is the pivot point. This is where good designs go to die. As a mold maker, I love plastic. We spend countless hours perfecting a mold's draft angles, its surface finish, and its cycle times to produce a beautiful, complex part. But for a product that holds standing water that people will breathe, plastic is a fundamentally flawed material.

Think about the user's experience. After a few days, they feel a slimy film on the inside of the tank. They see pink or black mold growing in the tight corners that your complex design created. They need to buy special brushes and chemicals to try and scrub it clean, but they can never reach every spot. They start to worry if the air they are breathing is healthy. The customer doesn't care about your clever ultrasonic transducer or your efficient fan. They care about the slime. And when they write their review, they don't blame the technology; they blame your brand for selling them a product that is a chore to maintain and feels unsafe.

Many plastics are porous on a microscopic level, which can harbor bacteria and biofilm.True

Unlike glass or stainless steel, the surface of most plastics contains microscopic pores where biofilm can anchor and become difficult to remove completely.

Customer reviews frequently cite 'difficulty cleaning' as a primary reason for dissatisfaction with humidifiers.True

A quick search of reviews for top-selling humidifiers on any major retail site will confirm that cleaning and mold growth are the most common and passionate complaints.

Why Is Material Hygiene the Real Deciding Factor in Humidifier Design?

Your brand's reputation is on the line with every use. Plastic components risk creating a health hazard in your customer's home. There's a better material that ensures hygiene and satisfaction.

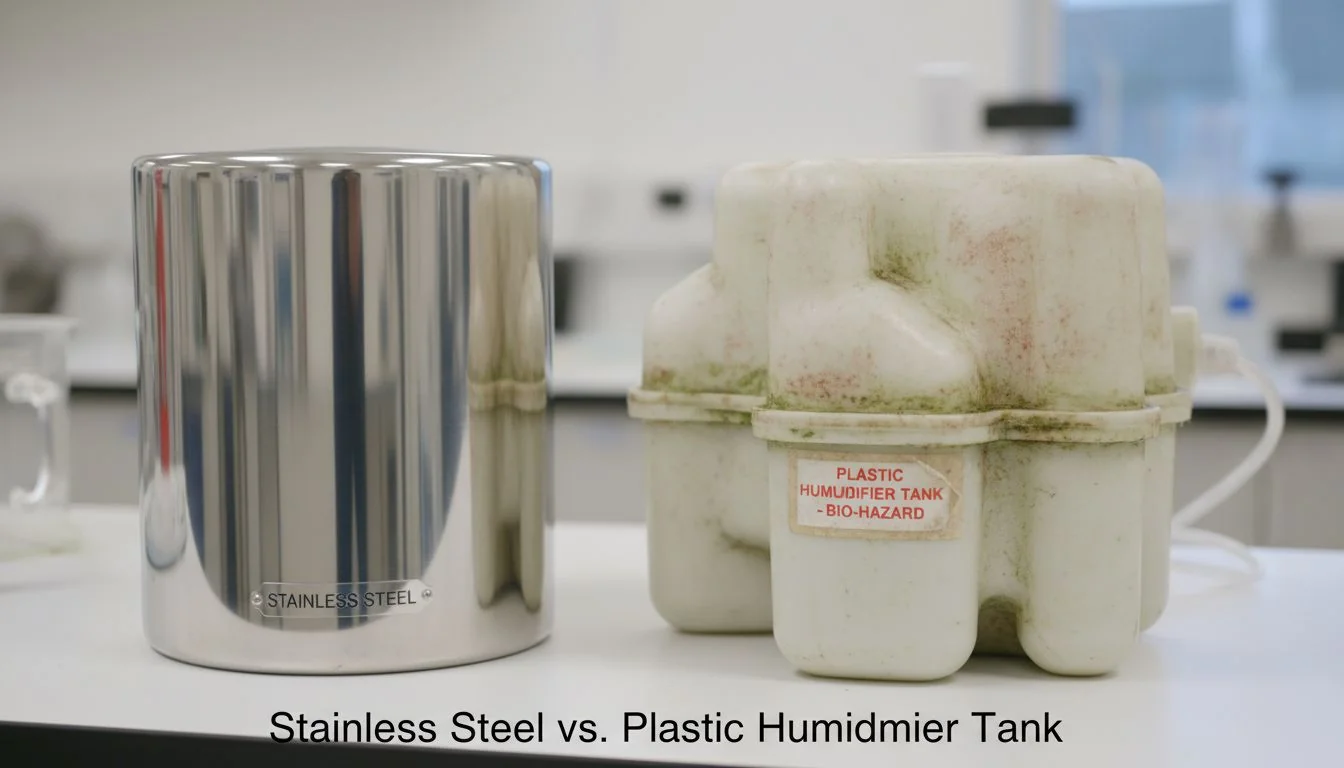

The real comparison isn't tech; it's materials. Plastic, used in 99% of humidifiers, is difficult to clean and promotes bacterial growth. Stainless steel, by contrast, is non-porous, easy to sterilize, and durable, directly solving the biggest user complaint and health concern: hygiene.

The Engineering Case for Stainless Steel

By now, the answer should feel obvious. If the biggest point of failure is the material that holds the water, then the solution is to choose a better material. Let's compare plastic to stainless steel from an engineering and user-experience perspective.

| Feature | Plastic | Stainless Steel |

|---|---|---|

| Hygiene | Porous, harbors biofilm | Non-porous, naturally hygienic |

| Cleanability | Difficult, needs special tools | Easy, wipe-down or dishwasher safe |

| Durability | Can crack, stain, and degrade | Highly durable, resists corrosion |

| User Perception | Cheap, disposable, unhealthy | Premium, clean, safe |

| Manufacturing | Injection molding (complex shapes) | Stamping, deep drawing, welding |

Yes, the manufacturing process for stainless steel is different. You can't just use the same injection mold. It requires expertise in metal forming. But the result is a product that solves the customer's #1 problem. You eliminate the source of the slime, the mold, and the 1-star reviews. You are no longer selling a disposable appliance; you are selling a durable, healthy, premium product. The choice of material completely reframes the product's value.

Stainless steel is non-porous, which prevents bacteria from seeping into the material's surface.True

This is why stainless steel is the standard material for commercial kitchens, medical equipment, and food processing. Bacteria can be wiped clean from the surface and cannot embed itself in the material.

Manufacturing a stainless steel water tank is always cheaper than injection molding a plastic one.False

The tooling and material costs for stainless steel are typically higher upfront than for plastic. However, the resulting product commands a higher price and builds greater brand loyalty, improving long-term profitability.

How Does Hisoair Offer the Best of Both Worlds?

You want the quiet efficiency of ultrasonic tech without the hygiene nightmare of plastic. This seems impossible, forcing a compromise. But one manufacturer has solved this exact problem.

Hisoair combines the superior performance of ultrasonic technology with the unmatched hygiene of a stainless steel water tank. This solves the industry's core flaw, offering a product that is both effective and genuinely easy to keep clean, protecting both the user's health and the brand's reputation.

Innovating Beyond the Commodity Trap

This is what excites me as a manufacturing professional. Hisoair didn't just pick a technology off the shelf. They looked at the entire system and identified the real point of failure. They saw the 1-star reviews and understood that the problem wasn't the mist, it was the mold.

So, they made a simple but revolutionary choice. They kept the quiet, efficient ultrasonic engine that customers love but replaced the flawed plastic tank with a clean, durable, food-grade stainless steel one. The tank is simple, with no tight corners, and can be easily wiped down or even put in the dishwasher. They solved the hygiene problem. For a product designer or a D2C brand, partnering with a manufacturer like Hisoair isn't just about sourcing a product. It's about sourcing a solution. You are getting a product that has been de-risked from the start because it eliminates the single biggest source of customer complaints. You are choosing an innovator, not a commodity supplier.

Hisoair manufactures ultrasonic humidifiers with stainless steel water tanks.True

This is their core product innovation and unique selling proposition in the crowded humidifier market.

A key selling point for Hisoair humidifiers is their ease of cleaning and improved hygiene compared to plastic models.True

Their marketing and product design are centered around solving the primary pain point of cleaning and health concerns associated with traditional plastic humidifiers.

Why Should You Stop Choosing a "Technology" and Start Choosing "Health"?

You're stuck in endless debates about tech specs. This focus is a distraction, leading you to overlook the one factor that truly determines customer satisfaction and brand loyalty.

Stop debating ultrasonic vs. evaporative. The real choice is between a product that's hard to clean and potentially unhealthy (plastic) and one that's hygienic and safe (stainless steel). Prioritizing the user's health and ease of use is the only path to a successful product.

The Final Word for Product Designers

Our journey started with a simple question about technology. But we discovered that the real enemy to a successful humidifier product isn't the wrong tech choice; it's the wrong material choice. As a designer, your goal is to create a product that people love to live with, not just one that works on day one. For a device that manages the air people breathe, that experience is defined by cleanliness and health.

The 1-star reviews are not lying. The slimy feel is real. The mold is real. And the customer's anxiety is real. You can solve all of this by making one smart decision at the beginning of your design process: choose a hygienic material. Choose stainless steel. The technology you put on top of it is secondary. By choosing a partner who understands this, you're not just building a better humidifier; you're building a brand that customers will trust with their health.

Long-term product success is heavily influenced by user experience, including maintenance and perceived safety.True

Products that are easy and safe to maintain generate higher customer satisfaction, better reviews, and stronger brand loyalty over time.

All consumers prioritize initial purchase price over long-term maintenance and hygiene.False

A growing segment of consumers, especially in health and wellness categories, are willing to pay a premium for products they perceive as safer, more durable, and easier to maintain.

Conclusion

The best humidifier isn't defined by its mist technology, but by its material. Choose hygiene, choose stainless steel, and build a brand that customers trust for their health.