You spend weeks perfecting the CAD model for a new water purifier, but the customer cannot see the filtration happening inside. They are scared of contaminants, and your design is the only thing standing between them and fear.

A water purifier is a "Trust Product1," meaning its value relies entirely on the user's belief in its function. To build this trust, we must engineer three specific elements into the product: visible third-party certifications (NSF/ETL), the use of inert premium materials like stainless steel, and complete transparency in the manufacturing supply chain.

Many designers think their job ends with the aesthetic shape and the mold flow analysis. I used to think that way too when I was just starting out on the factory floor. But in the water industry, the physical object is just a vessel for a promise. If the customer does not trust the vessel, they will not buy the promise. We need to stop asking for trust and start engineering it directly into the hardware.

Customers can visually verify water quality without testing tools.False

Filtration is invisible to the naked eye; customers rely on external cues like weight, material, and labels to judge performance.

A certification seal is a high-converting asset on a landing page.True

Trust seals like NSF or WQA act as third-party validation, significantly increasing consumer confidence and conversion rates.

Why Is the Water Purifier an "Invisible" Product?

You cannot see the bacteria dying, and you cannot see the lead being trapped.

The core function of a water purifier is invisible to the naked eye, making the physical housing the only proxy for quality. Since the user cannot verify the result, the design and weight of the product must communicate "Total System Integrity2" to bridge the gap between promise and reality.

When we design molds for consumer electronics, we focus on snap fits and surface finish. But for water purifiers, we are dealing with psychology. Since filtration is invisible, the customer looks for physical evidence. If the tank feels flimsy, they assume the filter is bad. If the housing has flash or sink marks, they assume the internal seals are leaking.

I have seen great internal technology fail because the external shell felt cheap. We have to visualize the invisible. We do this by treating the "Tank Material" as the primary indicator of quality. When a customer knocks on a solid stainless steel body, that sound communicates safety. It tells them the machine is robust.

Here is how we break down the "Invisible Product" challenge:

| Design Element | Customer Perception | Engineering Goal |

|---|---|---|

| Weight | Heaviness equals reliability. | Use denser materials or thick-wall molding. |

| Surface Finish | Smoothness equals cleanliness. | High-polish mold cavities to suggest hygiene. |

| Sound | Solid thud equals durability. | Ribbing and wall thickness to dampen vibration. |

As designers, we must ensure the "perceived quality" matches the "actual filtration quality." If there is a disconnect, trust is broken immediately.

The external housing quality has no impact on customer trust.False

Since filtration is invisible, customers use the external build quality as a direct proxy for internal performance.

Visualizing the invisible helps bridge the gap between promise and reality.True

Tangible cues like material weight and finish provide the physical evidence customers need to believe in the product's function.

How Does Certification Act as Your "Truth Serum"?

Why do we hide the most important sales tool in the back of the user manual?

Certification is not just a compliance requirement; it is a conversion rate optimization tool that should be front and center. By integrating seals like NSF and WQA directly into the product design and marketing, you provide the "Truth Serum" that validates your engineering claims instantly.

In the mold industry, we often view certifications as a headache. It means more paperwork and stricter material checks. But in the water market, certification is your best salesperson. I tell my clients: "Certification equals Conversion."

When you are designing the housing, do not just leave a blank space for a sticker. Design a dedicated, recessed area in the mold specifically for the NSF or WQA badge. Make it look like it belongs there permanently. This shows the customer that the product was born certified, not just stamped later.

We need to pitch "pre-certified platforms3" to our clients. If you are sourcing from a manufacturer like Hisoair, they often have pre-certified chassis options. This saves months of testing time. You are not just buying a plastic shell; you are buying a sales asset.

- The Placement Strategy: Put the seal near the dispensing point.

- The Design Integration: Use in-mold labeling (IML) or laser etching for permanence.

- The Marketing Angle: The seal is the hero, not the footnote.

By treating certification as a core design feature, we remove the customer's doubt before they even ask the question.

Certifications should be hidden in the manual to keep the design clean.False

Certifications are trust signals and should be prominent to reassure customers and drive conversion.

Pre-certified platforms can speed up time to market.True

Using platforms that already have NSF/ETL approvals reduces the testing burden and allows for faster product launches.

Why Are Materials the "Physical Evidence" of Purity?

Can a plastic tank really convince a mother that her water is safe from chemicals?

Materials serve as the physical evidence of purity, with stainless steel offering a "Scandal-Proof" pitch that plastic cannot match. Using inert materials prevents fears regarding BPA or microplastics, offering the customer peace of mind and protecting the brand from future litigation.

We have all heard the horror stories. Lead in cups. BPA in baby bottles. Microplastics in the ocean. These scandals stay in the consumer's mind. As a designer, you can try to explain that your polypropylene is "food grade," or you can just use stainless steel and end the argument.

I call this the "Scandal-Proof" pitch. When you specify a stainless steel body or tank in your design, you are using an "Inert Material." It does not react. It does not degrade. It does not leach.

From a manufacturing standpoint, working with steel is different than plastic injection molding. We have to deal with stamping dies and welding robots instead of just injection molds. But the payoff is huge.

The "Total System Integrity" Argument:

- The Promise: The filter removes contaminants.

- The Threat: The storage tank re-contaminates the water.

- The Solution: A steel tank ensures the water stays as pure as it was when it left the filter.

If you use a plastic tank, the customer might worry about the plastic taste or chemical leaching over time. Steel eliminates that variable. You are selling protection against future lawsuits and current anxiety.

Stainless steel is considered an inert material in water systems.True

Stainless steel does not leach chemicals or react with water, making it the gold standard for hygiene and safety.

Plastic tanks are always dangerous and contain BPA.False

Many high-grade plastics are safe and BPA-free, but consumer perception often favors steel due to past industry scandals.

How Does Transparency in the Supply Chain Build Trust?

Is your product made in a dirty workshop or a high-tech laboratory?

Transparency Marketing4 uses "Factory Footage" to prove that the product is manufactured in a clean, high-tech facility. By showcasing modern labs and automated assembly lines, you turn the manufacturing process itself into a marketing asset that validates the product's quality.

I have visited hundreds of factories. Some are dark and dirty. Others, like the facilities at Hisoair, look like operating rooms. As a designer, you know that a clean shop produces better parts. Fewer defects, tighter tolerances.

Your clients should use this. Encourage them to use "Factory Footage" in their marketing. Show the B-Roll of the injection molding machine. Show the robots assembling the filters.

When a customer sees a clean, automated production line, they subconsciously associate that cleanliness with the water they will drink. It is "Transparency Marketing."

Hisoair as the "Chief Trust Officer":

You need to elevate the role of your manufacturer. They are not just making parts; they are the "Guardians of Brand Reputation."

- Compliance: They handle the hard stuff like material safety data sheets.

- Testing: They run the life-cycle tests in their labs.

- Verification: They ensure every batch meets the spec.

By showing the "kitchen," you prove the food is clean. Don't hide the supply chain. If you have a good partner, show them off. It proves you have nothing to hide.

Factory conditions are irrelevant to the final product marketing.False

Showing a clean, high-tech factory builds consumer confidence in the hygiene and quality of the product.

The manufacturer plays a role in brand reputation management.True

Manufacturers ensure compliance and safety, acting as guardians of the brand's promise to the consumer.

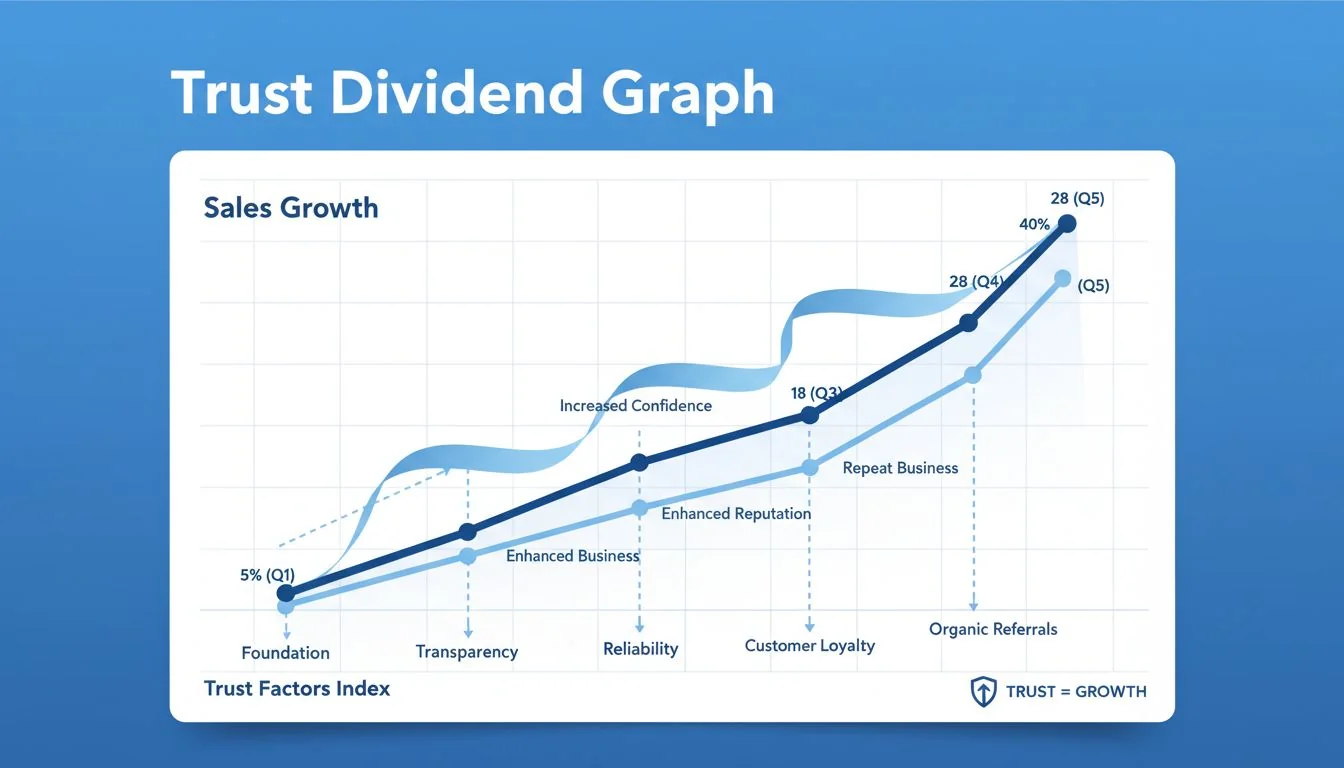

The "Trust Dividend": How Does It Impact Your Bottom Line?

Trust is not just a warm feeling; it is a financial metric.

The "Trust Dividend5" refers to the tangible financial benefits of engineering trust, including higher conversion rates, premium pricing power, and reduced return rates. By investing in certification and premium materials, brands avoid the high costs of customer skepticism and potential recalls.

We often argue with clients about the cost of the mold or the price of the steel. They want to cut costs. But I tell them to look at the "Trust Dividend."

When a customer trusts the product, three things happen to the bottom line:

- Conversion Speed: They buy faster. They don't need to read ten reviews. They see the NSF seal, they feel the steel, and they buy.

- Price Elasticity: You can charge more. Peace of mind is a premium feature. People will pay extra to know their children are safe.

- Lower Returns: When the product feels robust and has the paperwork to prove it works, "buyer's remorse" drops.

If you cheap out on the materials or skip the certification, you save money on Day 1. But you lose money every day after that in lost sales and returns.

We are not just designing a box. We are designing a business model based on reliability. The only way to sleep at night—for both you and your customer—is to know the product is scandal-proof and verified.

Engineering trust increases the cost without adding value.False

While initial costs may rise, the 'Trust Dividend' results in higher sales, better margins, and fewer returns.

Trust reduces the sales cycle duration.True

When trust signals are clear, customers make purchasing decisions faster, reducing the friction in the sales process.

Conclusion

We cannot simply ask customers for trust; we must build it into the device. By combining visible certification, inert materials, and supply chain transparency, we engineer a product that sells itself through safety and integrity.

References

-

Understanding the concept of a Trust Product can help you design products that resonate with consumer confidence. ↩

-

Discover how Total System Integrity can bridge the gap between product promise and consumer trust. ↩

-

Learn how using pre-certified platforms can expedite product development and enhance market readiness. ↩

-

Explore how showcasing manufacturing processes can enhance consumer trust in your brand. ↩

-

Discover how engineering trust can lead to financial benefits for your business. ↩