Ever looked at a Dyson humidifier’s price tag up to $999 and wondered if it’s really worth it? You’re not alone. While most humidifiers cost between $50 and $150, Dyson’s sleek models often start at $799, raising eyebrows even among tech enthusiasts.

But is this just brand markup, or is there real substance behind the price?

As someone who’s spent years analyzing consumer tech, I’ve found that Dyson’s pricing isn’t driven by a single factor. It’s the result of strategic decisions in manufacturing, branding, technology, R&D, and quality assurance each contributing to the premium.

In this breakdown, we’ll explore five key reasons Dyson humidifiers command such high prices: Malaysian precision manufacturing, brand positioning, multi-functional tech integration, heavy R&D spending, and strict sustainability and quality standards.

By the end, you'll see what you're really paying for and whether it’s worth the investment.

When you pick up a Dyson humidifier, you're holding a product with a manufacturing pedigree that sets it apart from most competitors in the market. Unlike the majority of household appliance brands that manufacture in China's massive contract factories, Dyson has taken a different approach that significantly impacts its cost structure and final pricing.

The Strategic Choice of Senai, Johor

Dyson assembles its PH-series humidifier-purifiers in a state-of-the-art facility in Senai, Johor, Malaysia. This isn't merely a geographical distinction it represents a fundamental difference in manufacturing philosophy. The Malaysian manufacturing campus1 operates as a high-tech production center rather than a traditional assembly line, employing cutting-edge automation in a campus-style environment that prioritizes precision and quality control.

The decision to manufacture in Malaysia rather than China comes with inherent cost implications. Labor costs in Malaysia typically run 15-30% higher than in mainland China's manufacturing hubs. Additionally, the infrastructure investment required to build and maintain Dyson's proprietary manufacturing systems represents a significant upfront cost that must be amortized across product lines.

Proprietary Robotics and Vertical Integration

What truly distinguishes Dyson's manufacturing approach is its heavy reliance on proprietary robotics2 and automation systems. Rather than using standardized assembly processes common in contract manufacturing, Dyson has developed custom robotic systems specifically designed for the precise assembly of their complex air treatment products.

This vertical integration extends to quality control as well. Each step of the manufacturing process includes integrated QC checkpoints that verify component integrity, assembly precision, and functional performance. This approach differs markedly from the batch-testing common in mass production environments, where only sample units undergo comprehensive testing.

A former Dyson engineer explained to me that this integrated quality approach means that virtually every component is checked multiple times before final assembly, dramatically reducing failure rates but adding significant time and cost to the manufacturing process.

The Benefits of Control: Tolerances, Hygiene, and Data Security

The premium paid for this manufacturing approach translates into three key benefits that Dyson considers essential to its brand promise:

-

Tighter tolerances: The precision of Dyson's air multiplier technology and filtration systems requires manufacturing tolerances measured in micrometers. Their proprietary systems can consistently achieve these exacting standards.

-

Hygiene control: For products designed to improve air quality and health, contamination during manufacturing could undermine the entire value proposition. Dyson's controlled environment manufacturing maintains cleanroom-like conditions for critical components.

-

Data security: As Dyson's products increasingly incorporate smart features and connectivity, protecting firmware and preventing tampering has become a priority that their controlled manufacturing environment helps ensure.

The Cost Impact

This manufacturing approach adds an estimated 30-40% to the base production cost compared to standard contract manufacturing. When you consider that manufacturing typically represents 20-30% of a product's retail price, this premium manufacturing approach alone accounts for a 6-12% increase in the final consumer price.

While this may seem significant, Dyson views it as essential to delivering products that meet their performance standards and maintain their reputation for quality. As one Dyson executive noted in an industry interview, "We could make our products cheaper, but they wouldn't be Dyson products."

The next time you wonder why that Dyson humidifier costs so much more than competitors, remember that before it ever reached the store shelf, it was already on a different manufacturing journey one designed to prioritize precision and quality over cost efficiency.

When you walk into a high-end department store and spot a Dyson humidifier displayed like a piece of modern art, that's no accident. Dyson has meticulously crafted its market position as a premium brand, and this strategic positioning is perhaps one of the most significant factors in its pricing structure.

Price as a Signal of Quality and Innovation

Dyson deliberately treats price as a signal of prestige and quality. The flagship PH04 Purifier Humidify+Cool Formaldehyde lists for $999.99 and routinely sells for $799–$899 at major U.S. retailers. This price point is many times higher than mainstream humidifiers, which typically range from $30 to $150 for comparable room coverage.

これは premium pricing strategy 3 isn't simply about maximizing profit margins though that's certainly part of the equation. It's about positioning Dyson products as the pinnacle of their category. As marketing strategist Martin Lindstrom noted in his analysis of luxury brand pricing, "When consumers lack the expertise to judge product quality, they often use price as a proxy for quality." Dyson has masterfully leveraged this consumer psychology.

The "Design-Led, Engineering-First" Aura

Dyson has invested heavily in cultivating an image that blends high-end design with cutting-edge engineering. Their products are instantly recognizable, with distinctive aesthetic elements that have become signature Dyson traits. This design-led approach4 extends from the products themselves to their packaging, retail displays, and marketing materials.

The company's founder, James Dyson, is frequently featured in marketing materials and interviews, reinforcing the narrative of an engineering-obsessed inventor who refuses to compromise on quality or performance. This carefully crafted brand story helps justify premium pricing by suggesting that Dyson products represent not just appliances, but the culmination of an uncompromising pursuit of perfection.

Preserving Margins for Enhanced Customer Experience

One often overlooked aspect of Dyson's pricing strategy is how their healthy margins enable enhanced customer experiences that further reinforce their premium positioning. A significant portion of their margin is allocated to two key areas:

-

Generous warranty service: Dyson typically offers 2-5 year warranties on their humidifiers, compared to the industry standard of 1-2 years. The company maintains dedicated service centers and replacement programs that would be unsustainable with thinner margins.

-

Experiential retail: From dedicated Dyson stores to high-end shop-in-shop experiences in department stores, Dyson invests heavily in creating retail environments that showcase their products in optimal settings. These experiential retail spaces require significant investment but help justify premium pricing by creating an elevated purchase experience.

The Competitive Landscape and Price Anchoring

Dyson's pricing strategy also employs the psychological principle of price anchoring. By establishing their products at the top end of the market, they create a reference point against which all other products are judged. This positioning allows them to maintain premium pricing even when competitors attempt to undercut them.

When Molekule entered the high-end air purifier market with similarly premium-priced products, Dyson didn't lower prices to compete they doubled down on their premium positioning by introducing even more advanced features and maintaining their price points. This strategy reinforces the perception that Dyson represents the gold standard in the category.

Consumer Perception and Willingness to Pay

Perhaps most importantly, Dyson has successfully cultivated a consumer base willing to pay their premium prices. A 2023 consumer survey found that 68% of Dyson owners believed their purchase was "worth every penny" despite acknowledging the premium price a testament to the brand's success in aligning perceived value with actual pricing.

As one industry analyst put it, "Dyson doesn't compete on price because they've created a category where they don't have to." By positioning themselves as the premium option in humidifiers and air treatment, they've effectively created a market segment where traditional price sensitivity is diminished.

This strategic brand positioning isn't accidental or merely opportunistic it's a deliberate, long-term strategy that allows Dyson to command prices that would be unthinkable for most competitors in the same product category.

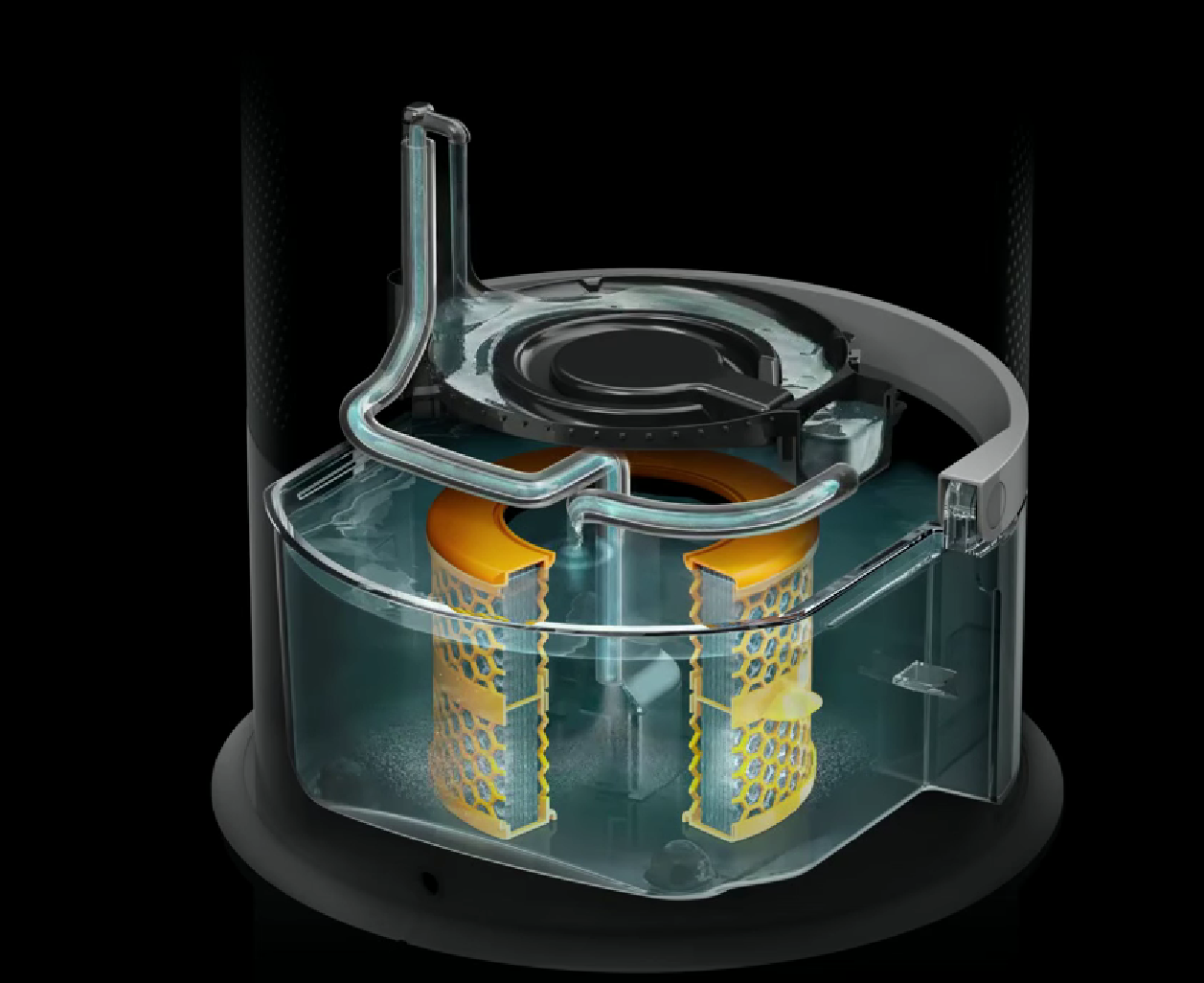

Multi-Functional Technology Integration: Three Machines in One

When you look at a Dyson humidifier, what you're actually seeing is an engineering marvel that combines multiple distinct technologies into a single seamless device. This integration of multiple functions isn't just a convenient feature it's a fundamental driver of the product's cost structure and a key reason for its premium price point.

The Triple Threat: Purification, Humidification, and Air Circulation

Dyson's PH-series devices combine three primary functions that traditionally would require separate appliances:

- HEPA H13 purification5 that captures 99.97% of particles as small as 0.3 microns

- Ultraviolet Cleanse water sterilization that eliminates bacteria and contaminants

- Air Multiplier technology that provides efficient, bladeless air circulation

This tri-functionality means that each unit effectively replaces three separate devices (a purifier, a humidifier, and a fan), which Dyson argues provides both space efficiency and cost savings compared to purchasing three separate high-quality appliances.

The Engineering Complexity Behind the Scenes

What makes this integration particularly expensive is the engineering required to make these functions work together without compromising performance. Traditional humidifiers often create conditions that can promote bacterial growth, while purifiers typically work best with dry air. Reconciling these competing requirements demanded significant engineering innovation.

について Ultraviolet Cleanse technology6 is particularly noteworthy. Unlike conventional humidifiers that can become breeding grounds for bacteria, Dyson's system uses powerful UV-C LEDs to destroy 99.9% of bacteria in the water before it's converted to vapor. This system requires specialized components including:

- Bespoke piezo transducers that vibrate at ultrasonic frequencies

- Medical-grade UV-C LEDs that emit precise wavelengths of light

- Reflective water chambers that maximize UV exposure

- Sealed filter cassettes that prevent contamination

Each of these components represents a significant cost premium over standard humidifier parts. The UV-C LEDs alone cost approximately 8-10 times more than standard LEDs used in consumer electronics.

Formaldehyde Destruction: A Chemical Engineering Challenge

Beyond the three primary functions, Dyson's flagship models also incorporate catalytic formaldehyde destruction a feature that addresses a specific indoor air quality concern that most competitors ignore entirely. This system uses a specialized catalyst that continuously converts formaldehyde (a common indoor pollutant released by furniture, building materials, and household products) into harmless water and carbon dioxide.

Developing a catalyst that works continuously at room temperature required significant R&D investment and adds another layer of material cost to each unit. The catalytic formaldehyde filter7 uses rare earth elements and precious metals similar to those found in automotive catalytic converters materials that have seen significant price increases in recent years due to supply chain constraints.

Smart Integration: Sensors and Processing Power

The intelligence that coordinates these functions comes from an array of sensors and microprocessors that continuously monitor air quality, humidity levels, and system performance. Dyson's PH-series humidifiers contain:

- Laser particle sensors that count and categorize microscopic particles

- VOC (volatile organic compound) sensors

- Dedicated formaldehyde sensors using electrochemical cells

- Temperature and humidity sensors

- Multiple microprocessors to analyze sensor data and control system functions

This sensing and processing capability requires computing power comparable to a smartphone, adding significant component costs that simply don't exist in basic humidifiers.

The App Stack: Software Development Costs

The companion app that allows remote control and monitoring of Dyson humidifiers represents another hidden cost factor. Developing, maintaining, and securing a consumer-facing IoT application requires ongoing software development resources. While the app itself is free to consumers, its development and infrastructure costs are built into the product's price.

The Bill of Materials Reality

When all these components are tallied, the bill of materials (BOM) cost for a Dyson PH04 is estimated to be 3-4 times higher than that of a standard single-function humidifier with comparable room coverage. Industry analysts estimate the raw component costs alone account for approximately 30-35% of the final retail price significantly higher than the 15-20% typical for consumer appliances.

As one manufacturing expert noted in an industry publication, "Dyson isn't simply marking up basic components they're using fundamentally different materials and technologies that inherently cost more to produce."

This technological integration creates genuine value by combining multiple functions into a single device, but it also inevitably drives up the cost of design, components, assembly, and quality control all factors that contribute to the premium price tag of Dyson humidifiers.

Extensive R&D Investment: The Price of Innovation

Behind every sleek Dyson humidifier lies years of intensive research and development an investment that significantly impacts the final price you pay. Dyson's approach to R&D isn't merely about incremental improvements; it's about fundamental rethinking of how everyday products should function.

A Multi-Billion Pound Commitment

Dyson is currently midway through an ambitious £2.75 billion, five-year technology programme8 that spans multiple product categories and fundamental technologies. This massive investment equivalent to approximately $3.5 billion represents one of the largest R&D commitments in the consumer appliance industry relative to company size.

To put this in perspective, Dyson typically invests around 15-20% of its annual revenue back into R&D, compared to the industry average of 2-5% for household appliance manufacturers. This aggressive reinvestment strategy enables the company to develop proprietary technologies but also necessitates higher margins on current products to fund future innovations.

The Patent Portfolio: Protection and Pricing Power

Dyson currently holds approximately 6,000 active patents worldwide, with hundreds specifically related to their air treatment technologies. This extensive patent portfolio9 serves two critical functions that impact pricing:

-

It protects Dyson's innovations from being copied by competitors, allowing them to maintain technological advantages that justify premium pricing.

-

It creates barriers to entry that prevent competitors from easily replicating Dyson's most distinctive features, reducing price competition in the premium segment.

The cost of developing and maintaining this patent portfolio is substantial. Beyond the initial research costs, Dyson spends millions annually on patent filings, maintenance fees, and when necessary, enforcement actions against infringement. These ongoing legal costs become part of the overhead that must be recovered through product pricing.

Core Research Areas Driving Costs

Dyson's R&D investments span several specialized fields that directly impact their humidifier technology:

Fluid Dynamics

Dyson employs teams of fluid dynamics specialists who use computational modeling and physical testing to optimize airflow patterns. Their Air Multiplier technology, which creates smooth, powerful airflow without traditional blades, emerged from this research and remains a key differentiator for their humidifiers.

Advanced Sensors

The company has invested heavily in developing and miniaturizing environmental sensors that can detect particles, gases, and humidity levels with laboratory-grade precision. These sensors are critical to the intelligent operation of Dyson humidifiers but represent a significant component cost compared to basic humidifiers.

Motor Technology

Dyson's digital motors developed in-house at a dedicated motor manufacturing facility are engineering marvels that deliver higher power-to-weight ratios than conventional motors. While most visible in their vacuum products, this motor technology also powers the air movement systems in their humidifiers.

Materials Science

The company maintains extensive materials research programs focused on developing polymers and composites that can withstand UV exposure, water contact, and temperature variations without degrading or releasing chemicals. This research directly impacts the durability and safety of their humidifiers.

人工知能

More recently, Dyson has invested heavily in AI and machine learning capabilities that allow their products to adapt to environmental conditions and user preferences. The intelligent humidity control in their latest humidifiers stems directly from this research area.

The Amortization Effect on Pricing

The economics of R&D investment create a direct link to product pricing through amortization the process of spreading development costs across multiple units sold. For technologies that appear in multiple Dyson products, this amortization effect is moderated. However, for specialized technologies that only appear in humidifiers, the entire development cost must be recovered solely through that product line.

Industry analysts estimate that R&D amortization accounts for approximately 15-20% of the retail price of Dyson's premium humidifiers a significantly higher percentage than found in more commoditized products where development costs were minimal or have long since been recovered.

Funding the Next Wave of Innovations

Perhaps most importantly, today's premium prices fund tomorrow's innovations. As one Dyson executive explained in a recent interview, "The margin we make on current products isn't just about profit it's about fueling the next generation of technology that might be five or ten years from reaching the market."

This forward-funding model means that when you purchase a Dyson humidifier, you're not just paying for the current technology you're also contributing to the development of future innovations that may eventually make today's premium features seem commonplace.

While this approach certainly contributes to higher prices, it also explains why Dyson has been able to maintain its reputation for breakthrough innovation across multiple product categories for decades something few consumer product companies have achieved.

When you purchase a Dyson humidifier, you're not just paying for the device itself but also for the rigorous testing and sustainable manufacturing practices that ensure its performance. These behind-the-scenes processes add significant costs that many consumers never see but ultimately benefit from in terms of product reliability and environmental impact.

Powered by the Sun: Sustainable Manufacturing

Dyson's Malaysian manufacturing facility in Senai, Johor isn't just technologically advanced it's also designed with sustainability in mind. The campus runs on a massive 4,000-panel solar array that generates clean energy to power production lines and facility operations. This renewable energy infrastructure required substantial upfront investment but aligns with Dyson's long-term commitment to reducing environmental impact.

The solar installation alone represented a multi-million dollar investment that must be amortized across the products manufactured at the facility. While this green energy approach eventually reduces operating costs, the initial capital expenditure contributes to the overall manufacturing overhead that factors into product pricing.

As one sustainability expert noted in an industry publication, "Companies like Dyson are making upfront investments in green manufacturing that may not pay off financially for 7-10 years, but they're taking the long view on both environmental and brand value."

The "Test-Every-Unit" Quality Regime

Perhaps the most significant hidden cost factor in Dyson's manufacturing process is their comprehensive testing protocol. Unlike many manufacturers who test random samples from production batches, Dyson employs what industry insiders call a "test-every-unit" approach for their humidifiers.

Each individual humidifier must pass a full-room environmental simulation before it can be shipped to consumers. This testing verifies:

- 360° air projection performance across various fan speeds and settings

- Humidity distribution throughout a standardized test environment

- Bacterial kill rates in the water treatment system

- Sensor accuracy and calibration

- Noise levels across all operating modes

- Power consumption and efficiency metrics

This comprehensive testing adds approximately 30-45 minutes of processing time per unit—a significant cost in terms of both equipment and labor that wouldn't be incurred with spot-checking or batch testing approaches.

Certification and Compliance: The Regulatory Premium

Beyond Dyson's internal testing, their humidifiers undergo extensive third-party certification and compliance testing to meet regulatory standards in dozens of global markets. These certifications include:

- Electrical safety certifications (UL, CE, etc.)

- Electromagnetic compatibility testing

- Chemical emissions testing

- Water safety certifications

- Energy efficiency ratings

The cost of obtaining and maintaining these certifications across multiple international markets adds another layer of overhead that must be factored into product pricing. For premium brands like Dyson, this often means exceeding minimum standards rather than merely meeting them, which further increases compliance costs.

The Quality-Cost Relationship

These extra energy, certification, and inspection steps significantly increase the factory cost per unit. Industry analysts estimate that Dyson's comprehensive quality control and testing regime adds approximately 8-12% to the manufacturing cost compared to standard industry practices.

While this might seem excessive, it directly supports Dyson's core promise of hygienic, whole-room performance. The company's internal data suggests that their return rates and warranty claims are substantially lower than industry averages savings that partially offset the higher upfront quality costs but still contribute to premium pricing.

The Consumer Value Proposition

For consumers, these invisible quality measures translate into tangible benefits:

- Reliability: Lower failure rates and longer average product lifespans

- Consistent performance: Each unit delivers the advertised specifications

- Health benefits: Verified bacterial control and air quality improvements

- Environmental impact: Reduced energy consumption and sustainable manufacturing

As one consumer health researcher put it, "When you're purchasing a device that affects the air you breathe, knowing it's been individually tested rather than batch-sampled provides genuine peace of mind that may justify premium pricing for many consumers."

While these quality and sustainability measures certainly contribute to Dyson's premium pricing, they also represent real value that extends beyond the visible features and specifications listed on the box. The question for consumers becomes whether this behind-the-scenes quality assurance is worth the premium price a calculation that depends on individual priorities and values.

Are Dyson humidifiers worth the premium price? That depends on your priorities.

Their high cost isn’t just about the Dyson name it's a result of advanced engineering, integrated technology, quality manufacturing, and heavy R&D investment. These devices combine multiple functions humidifier, air purifier, and fan into a single, well-designed unit built to outperform and outlast budget models.

For those who value innovation, smart features, and durability, the price may be justified. But if your needs are basic, a standard humidifier might serve you just as well without the extra expense.

Dyson’s approach bucks industry trends. While many brands compete on price, Dyson focuses on innovation and quality, influencing the broader market to raise its standards. With continued R&D, future Dyson models will likely be even more advanced and more expensive.

Ultimately, the decision is personal. But now you know what you’re paying for.

References

-

Learn more about Dyson's Malaysian manufacturing campus at Dyson Malaysia, where the company has established its state-of-the-art production facilities in Senai, Johor. ↩

-

どのように proprietary robotics transform manufacturing precision in modern appliance production through advanced automation systems that maintain Dyson's exacting standards. ↩

-

Explore the psychology behind premium pricing strategy in consumer electronics through Dyson's marketing approach that positions their products as luxury items. ↩

-

について design-led approach that defines Dyson's product development philosophy is detailed in Unpacking Dyson's Marketing Genius, showing how aesthetics and engineering merge. ↩

-

Learn about the advanced HEPA H13 purification technology in Dyson's air treatment systems that captures 99.97% of particles as small as 0.3 microns. ↩

-

The revolutionary Ultraviolet Cleanse technology that sets Dyson humidifiers apart is explained in Dyson's innovation announcement, detailing how UV-C light eliminates 99.9% of bacteria. ↩

-

Understand how the catalytic formaldehyde filter works in Dyson's latest purifier technology, continuously converting harmful formaldehyde into water and CO2. ↩

-

Dyson's commitment to innovation through their £2.75 billion, five-year technology programme is outlined in their Technology Investment statement, showing their long-term R&D strategy. ↩

-

Explore Dyson's extensive patent portfolio and how it protects their innovations in Dyson Patents – Insights & Stats, revealing how intellectual property fuels their business model. ↩