Your product looks clean and modern. But what if its material is secretly a breeding ground for bacteria? This hidden flaw can destroy your brand's reputation with every use.

Stainless steel is the most hygienic material because its surface is non-porous1. This means there are no microscopic holes or cracks for bacteria, mold, and viruses to hide in. It can be cleaned and sanitized to a much higher degree than porous materials like plastic.

As a product designer, you live and die by the details. You obsess over tolerances, aesthetics, and user experience. But there's one detail that often gets overlooked until it's too late: the microscopic2 reality of your chosen material. I've spent my career in mold manufacturing, and I've seen brilliant designs fail because of a fundamental material flaw. They chose a material that looked hygienic but was anything but. This is a critical distinction that can make or break your product in the long run. Let's dive into the science of why this matters more than you think.

All plastics are porous on a microscopic level.真

Even the smoothest-looking plastics have microscopic pores and are susceptible to micro-scratches, which can harbor bacteria. This is a fundamental property of polymer structures.

BPA-free plastic is as hygienic as stainless steel.偽

BPA-free addresses a chemical leaching concern, not the physical structure of the material. BPA-free plastic is still porous and prone to scratches where microbes can grow.

1. Introduction: The "Hygienic-Looking" vs. "Truly Hygienic" Problem?

Your plastic appliance looks pristine on the shelf. But after a few months of use, customers complain about a strange smell or slime. You've created a hidden hygiene problem.

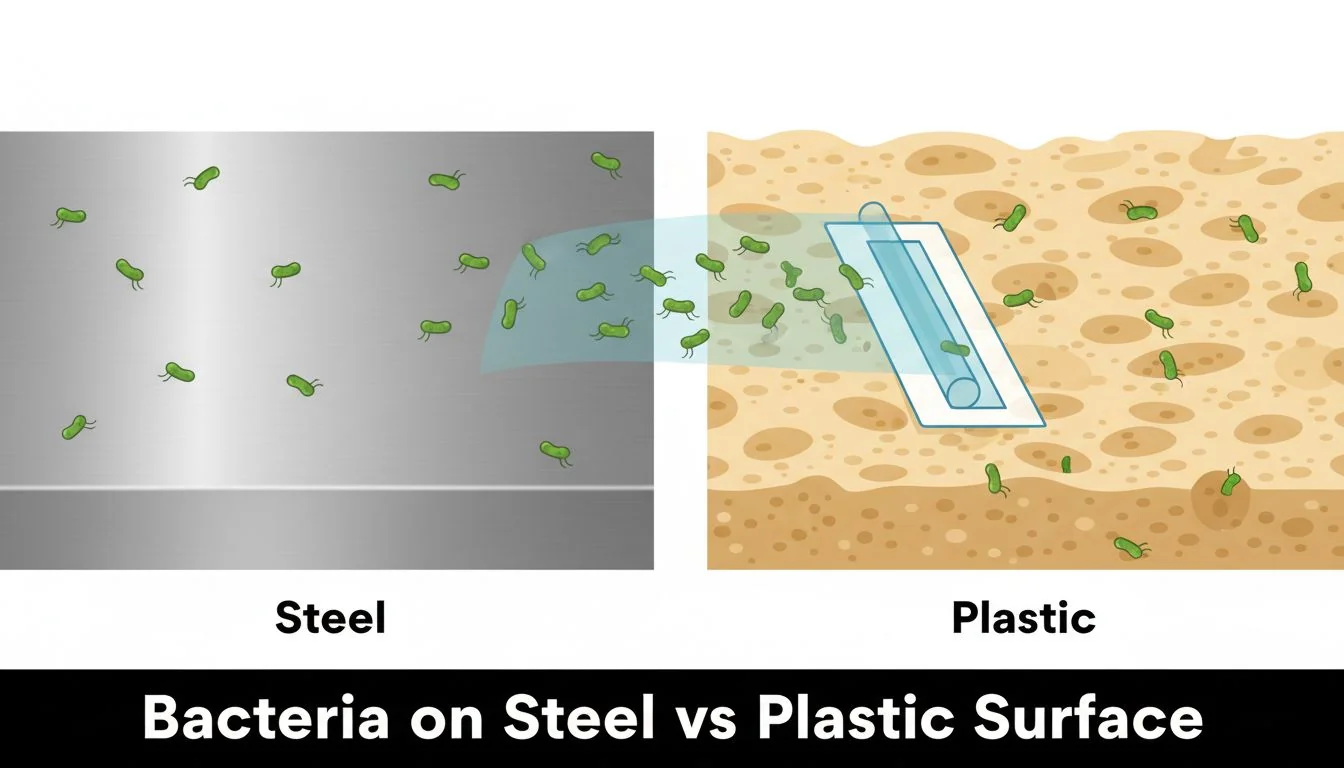

The problem is the difference between a surface that looks clean and one that is microscopically clean. Plastic may appear smooth, but it's a porous material that traps bacteria, while non-porous stainless steel offers no place for germs to hide, ensuring true hygiene.

Dive Deeper

When we design products, especially for air and water, we focus on a clean aesthetic. We want smooth, white, minimalist designs. Plastic is often the go-to material to achieve this look quickly and cheaply. The problem is that this is a visual trick. The surface looks non-porous to the naked eye, but the reality is very different. I learned this the hard way early in my career with a client who made water pitchers. The design was beautiful, but the 1-star reviews about "pink slime" and "musty smells" started rolling in after six months. The issue wasn't the design; it was the material. We were selling a product that looked hygienic but was fundamentally flawed at a microscopic level.

Key Differences: Appearance vs. Reality

| 特徴 | "Hygienic-Looking" (Plastic) | "Truly Hygienic" (Stainless Steel) |

|---|---|---|

| Surface (Macro) | Smooth, clean, modern appearance. | Smooth, premium, durable appearance. |

| Surface (Micro) | Porous, with microscopic pits and valleys. | Non-porous, exceptionally smooth. |

| 耐久性 | Prone to micro-scratches3 from cleaning. | Highly resistant to scratches and wear. |

| Long-Term State | Becomes a breeding ground for bacteria. | Remains inert and easy to sanitize. |

This distinction is everything. You are not just designing an object; you are designing an environment that will be in constant contact with water or air, and the microbes they carry.

A material's appearance is a reliable indicator of its hygienic properties.偽

Many materials, like plastic, can look smooth and clean but be porous at a microscopic level, making them less hygienic than they appear.

Stainless steel's hygienic properties are due to its non-porous surface.真

The lack of pores on a stainless steel surface prevents microorganisms from embedding themselves, making it easier to clean and sanitize effectively.

2. The Microscopic Failure of Plastic (Even "BPA-Free")?

You chose BPA-free plastic4, thinking it was the safe, responsible choice. But customers are still complaining about odors and mold, and you can't figure out why. It's an unseen enemy.

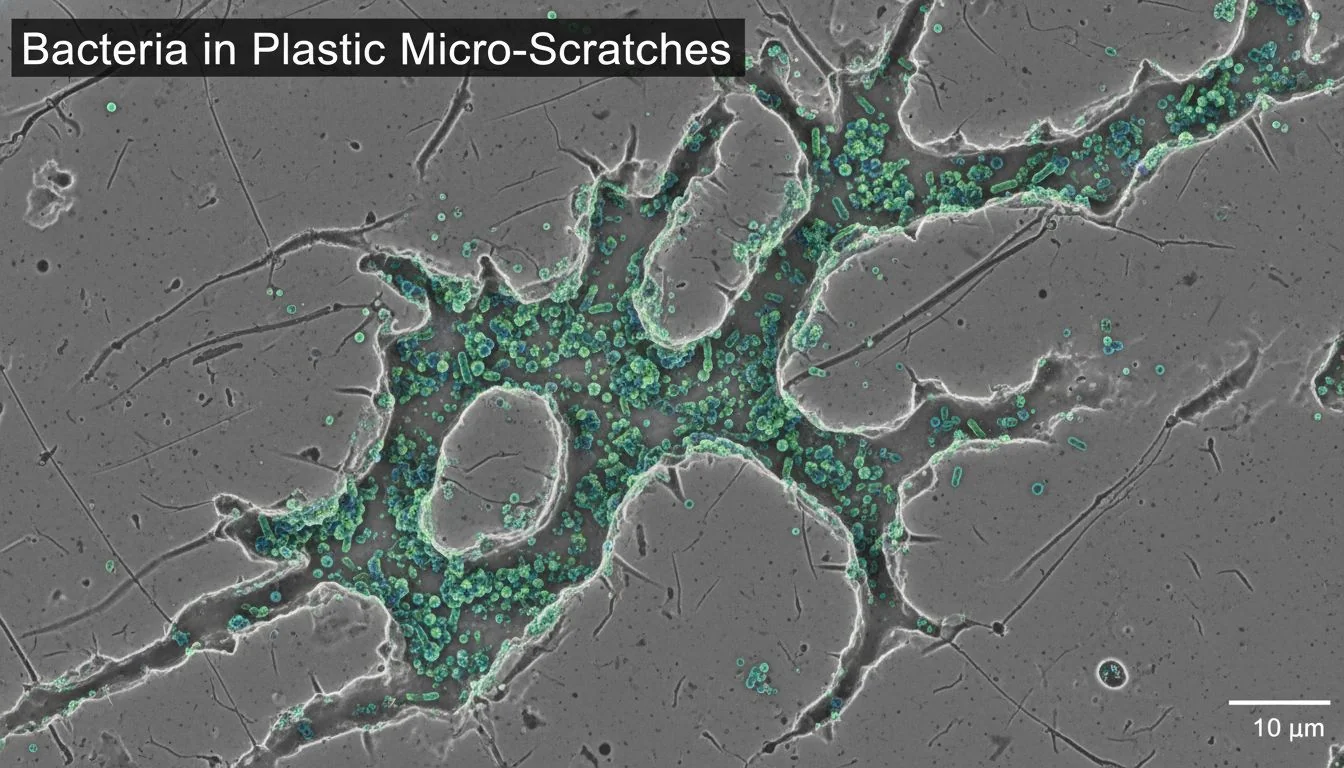

The failure is in the pores. All plastics are porous and develop micro-scratches with every use and cleaning. These tiny imperfections become permanent homes for bacteria and biofilm5, which are impossible to fully remove, regardless of the plastic being "BPA-free."

Dive Deeper

This is the argument that changes everything for a designer. You have to show your customer the enemy they cannot see. Imagine a perfectly smooth sheet of plastic under a powerful microscope. It's not a flat plane. It's a landscape of tiny hills and valleys. Now, imagine cleaning it with a brush or sponge. You're not just wiping it clean; you're carving microscopic canyons into that landscape. These are micro-scratches. For bacteria, a micro-scratch isn't a tiny flaw; it's a perfect, protected trench to build a colony, which we call a biofilm. Once a biofilm is established, it's incredibly difficult to remove. It protects the bacteria from cleaning agents and allows them to multiply. "BPA-free" is a chemical safety claim, not a physical one. It does nothing to change the porous nature of plastic.

The Lifecycle of a Biofilm on Plastic

| ステージ | 説明 | Implication for Your Product |

|---|---|---|

| 1. Initial Use | The plastic surface seems smooth. | Product functions as expected. |

| 2. Cleaning & Wear | Micro-scratches form from normal use. | The "unseen enemy" now has a foothold. |

| 3. Bacterial Attachment | Bacteria settle into the scratches and pores. | The start of a contamination problem. |

| 4. Biofilm Formation | Bacteria create a slimy, protective matrix. | Odors, bad taste, and visible slime appear. |

| 5. Customer Complaint | The user cannot clean the product effectively. | A 1-star review is born. |

This is a predictable failure mode. As a designer, choosing plastic for a wet environment is, in effect, designing a future customer service problem.

Regular cleaning can remove all bacteria from plastic surfaces.偽

While cleaning removes surface bacteria, it cannot effectively reach microbes within the material's pores and micro-scratches, where biofilms can form and persist.

Micro-scratches on plastic surfaces increase the risk of bacterial contamination.真

These scratches create protected niches where bacteria can attach and multiply, forming biofilms that are resistant to cleaning and sanitizing efforts.

3. The Scientific Superiority of Stainless Steel?

You need a material that doesn't just look clean but stays clean. You need a material that science, not just marketing, proves is more hygienic. What is the definitive choice?

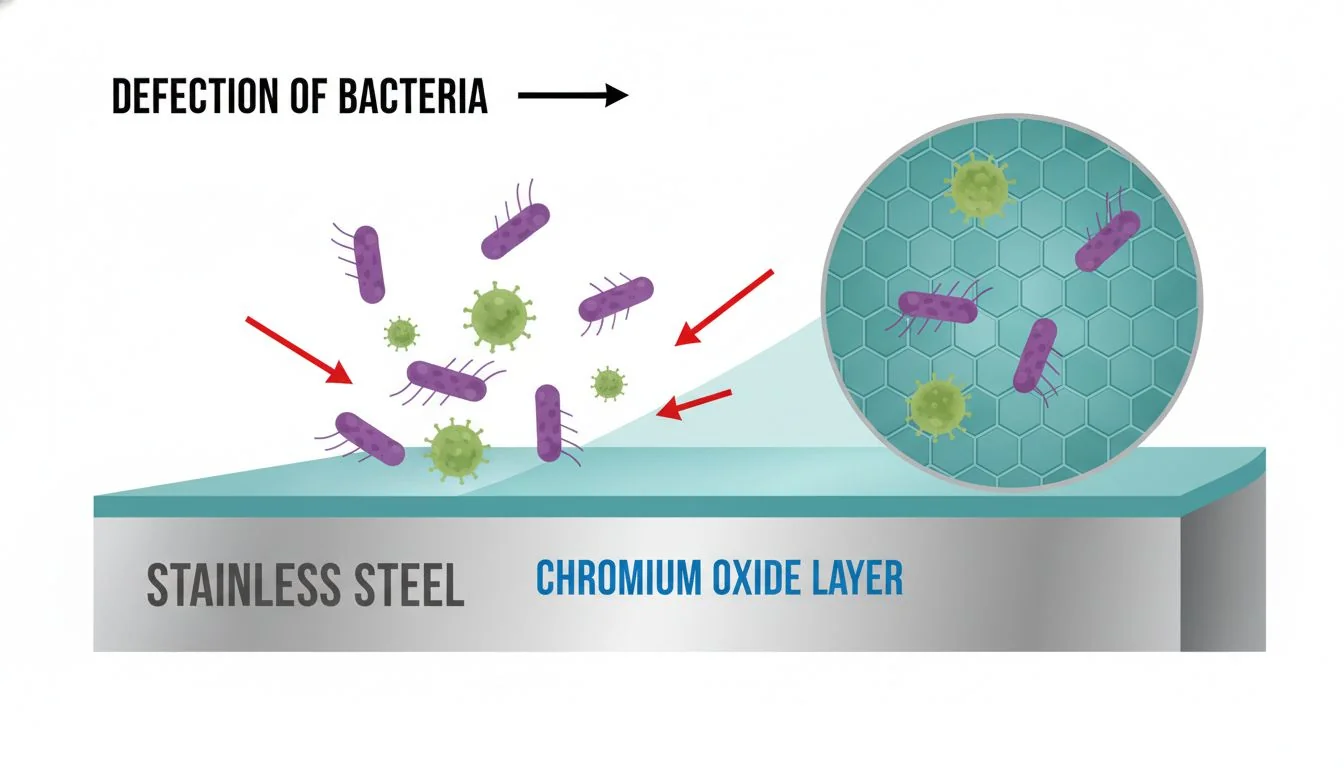

The scientific superiority of stainless steel comes from its non-porous and passive surface. The chromium oxide layer6 creates an inert, microscopically smooth barrier that gives bacteria nowhere to attach, hide, or grow, ensuring it can be sanitized completely.

Dive Deeper

Let's get into the core science. Stainless steel's magic lies in its composition, specifically its chromium content. When exposed to oxygen, the chromium forms an incredibly thin, invisible, and durable layer on the surface called the chromium oxide passive film. This layer is the key. First, it's "passive," meaning it's chemically non-reactive. It doesn't corrode, rust, or leach chemicals into the water or air. Second, and most importantly for hygiene, it's non-porous. Think of the difference between a sponge and a sheet of glass. You can never truly sanitize a used sponge because bacteria live deep inside its pores. But you can sanitize glass to perfection because its surface is completely sealed. Stainless steel is like that sheet of glass. There are no microscopic pits, pores, or valleys for bacteria to gain a foothold. When you wipe it clean, you are removing everything.

Comparing Material Surfaces

| Property | プラスチック | Stainless Steel |

|---|---|---|

| Surface Structure | Porous | Non-Porous |

| Surface Chemistry | Can be reactive, leach chemicals | Passive, inert (due to chromium oxide) |

| Scratch Resistance | Low (creates havens for bacteria) | High (maintains smooth surface) |

| Cleanability | Deceptive (biofilm remains in pores) | True (surface can be fully sanitized) |

This isn't a matter of opinion; it's a fundamental difference in material science. Choosing steel is choosing a surface that is actively hostile to microbial life.

Stainless steel is naturally antibacterial.偽

Stainless steel is not inherently antibacterial; it does not kill bacteria on contact. Its hygienic properties come from its non-porous surface, which makes it easy to clean and prevents bacteria from hiding.

The passive layer on stainless steel can self-heal if scratched.真

If the surface of stainless steel is scratched, the exposed chromium will react with oxygen in the air to instantly reform the protective passive chromium oxide layer, maintaining its corrosion resistance and smooth profile.

4. What "304 Food-Grade" (SUS304) Actually Means?

You've heard the term "food-grade stainless steel," but what does it actually mean for your design? Is it just marketing jargon, or is it a technical standard you can leverage?

"304 Food-Grade7" (also known as SUS304 or 18/8) is a specific alloy of stainless steel with excellent corrosion resistance and formability. It's a trusted standard for hygiene, used in surgical tools, commercial kitchens, and premium brands like Yeti, making it a powerful marketing weapon.

Dive Deeper

As a designer, specifications are your language. So let's be specific. "304" isn't just a random number. It's a grade that guarantees a certain composition, typically 18% chromium and 8% nickel (which is why you'll also see it called "18/8" steel). This specific blend gives it the ideal combination of properties for hygienic applications. The chromium provides that all-important corrosion resistance, and the nickel enhances its durability and formability, which is critical for manufacturing complex shapes. When you specify "304 Food-Grade Stainless Steel" in your design, you're not just choosing a material. You are borrowing decades of trust built by other industries. Your customer may not know the science of porous vs. non-porous, but they know that surgeons don't use plastic tools. They know that professional chefs don't work on plastic counters. They've paid a premium for a Yeti cooler because they trust its durability. By using SUS304, you instantly align your brand with this ecosystem of trust, quality, and hygiene.

Leveraging "304" in Your Brand Story

| Your Claim | The Customer's Association |

|---|---|

| "Made with 304 Surgical-Grade Steel" | "This is as clean as a medical device." |

| "Built with the same steel as commercial kitchens" | "This is professional, durable, and safe." |

| "Uses premium 18/8 stainless steel" | "This is high-quality, like other premium products I own." |

I once worked with a startup making high-end humidifiers. They were struggling to stand out. We switched their water tank from ABS plastic to a deep-drawn SUS304 tank. They didn't just change a part; they changed their story. They went from being another plastic appliance to a "premium, hygienic air-purifying device." It became their single biggest marketing advantage.

All stainless steel is 'food-grade'.偽

Only specific grades of stainless steel, like 304 and 316, are considered 'food-grade' due to their specific composition (like high chromium and nickel content) which ensures high corrosion resistance and prevents leaching.

The numbers '18/8' refer to the percentage of chromium and nickel in 304 stainless steel.真

18/8 stainless steel contains approximately 18% chromium and 8% nickel. This composition is what gives 304 grade its signature corrosion resistance and durability.

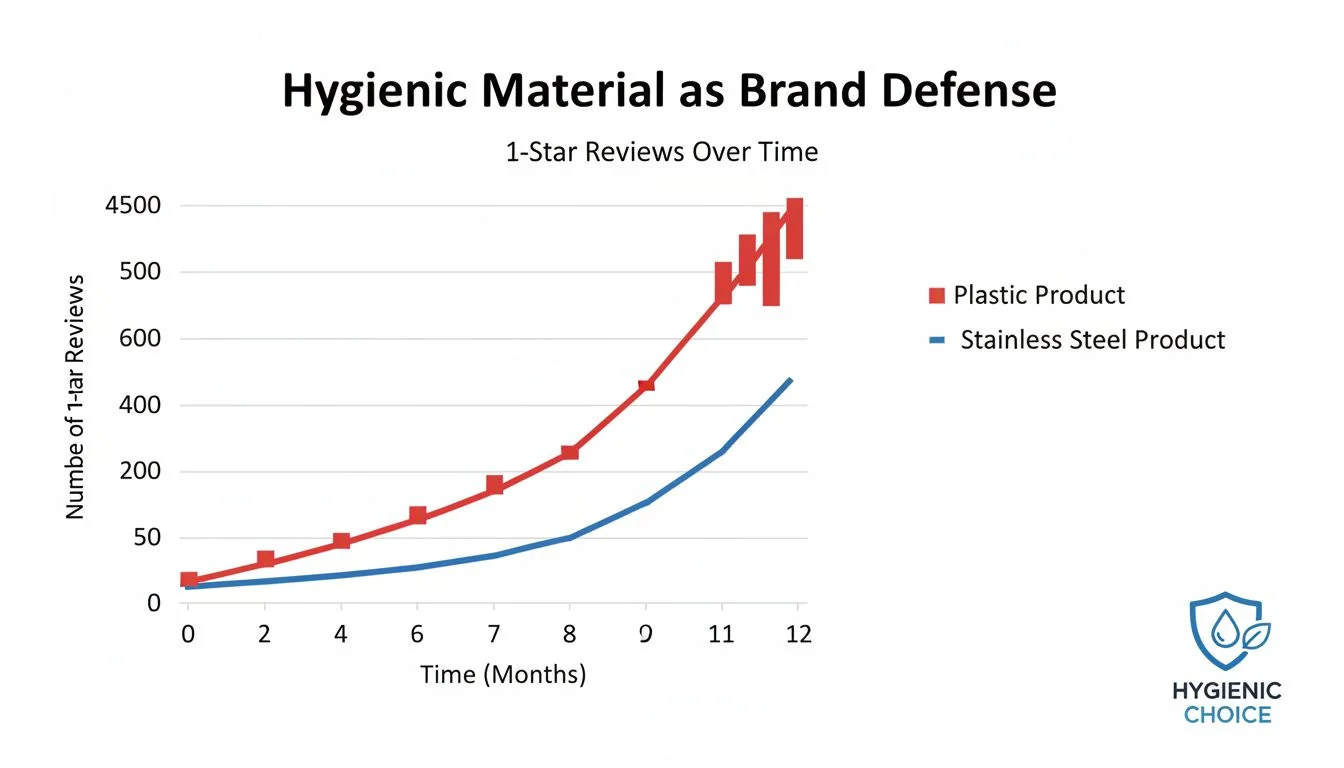

5. Why Is "Hygienic Material" Your #1 Brand Defense?

You think of material as a cost on a bill of materials. But what if it's actually your best defense against bad reviews and your strongest justification for a premium price8?

A hygienic material is a business strategy. It directly reduces 1-star reviews about mold and odors, which protects your brand's reputation. It also provides a tangible, scientific reason for customers to pay a premium, boosting your profit margins.

Dive Deeper

Let's connect this back to your P&L. Every 1-star review that says "smells musty" or "I can't get the slime out" is a direct hit to your sales. It kills conversion rates and erodes brand trust. A plastic appliance with a water tank is a ticking time bomb for these kinds of reviews. By switching to 304 stainless steel, you are not just upgrading a component; you are proactively eliminating the root cause of your most damaging customer complaints. This is your brand defense. But it's also your offense. It allows you to change the conversation from "How much does it cost?" to "Why is it better?". You can now confidently explain why your product is worth $150 when a competitor's is $80. The reason is tangible: it's a long-term solution to a hygiene problem, not a short-term product that becomes a petri dish. However, be warned: simply choosing steel isn't enough. I've seen companies fail because they couldn't properly manufacture it. Working with steel requires expertise in processes like deep-draw stamping and ensuring perfect seals between metal and electronics. This is where your choice of an engineering and manufacturing9 partner becomes your true defensible advantage.

The Business Case: Plastic vs. Stainless Steel

| Business Metric | Plastic Appliance | Stainless Steel Appliance |

|---|---|---|

| Unit Cost | より低い | より高い |

| Customer Reviews | Risk of negative reviews on hygiene. | Positive reviews on quality, durability, cleanliness. |

| Brand Perception | Disposable, cheap. | Premium, permanent, trustworthy. |

| Pricing Power | Low (competes on price). | High (justifies a premium price). |

| Long-Term Value | Sells a product. | Sells a solution and peace of mind. |

Choosing steel isn't an expense. It's an investment in your brand's reputation and profitability.

Choosing a more expensive material like stainless steel always leads to lower profits.偽

While the unit cost is higher, the ability to command a premium price, reduce negative reviews, and build a stronger brand can lead to significantly higher overall profitability.

Manufacturing with stainless steel requires specialized engineering and tooling.真

Processes like deep-drawing, welding, and sealing stainless steel components are more complex and require more advanced machinery and expertise than injection molding plastic, creating a barrier to entry for competitors.

6. Conclusion: Stop Selling a "Hygiene Problem." Start Selling a Solution.

Stop designing products with a built-in failure. By choosing 304 stainless steel, you move beyond aesthetics and deliver true, scientifically-proven hygiene, building a brand that customers trust and value.

References

-

Understanding non-porous materials can help you choose safer options for hygiene in products. ↩

-

Exploring microscopic structures reveals why some materials harbor bacteria while others do not. ↩

-

Learning about micro-scratches can help you avoid hygiene pitfalls in product design. ↩

-

Investigating BPA-free plastic can clarify its limitations in hygiene compared to alternatives. ↩

-

Learning about biofilm can help you understand hidden hygiene issues in common materials. ↩

-

Exploring the chromium oxide layer can reveal why stainless steel is preferred for hygiene. ↩

-

Discovering the significance of 304 food-grade steel can enhance your product's credibility. ↩

-

Understanding the value of stainless steel can help you position your product effectively. ↩

-

Exploring engineering challenges can prepare you for successful product development. ↩