You might be struggling to decide which air purifier model to prioritize for your next product line. Making the wrong choice between portable and wall-mounted units can leave you with stagnant inventory and low profits.

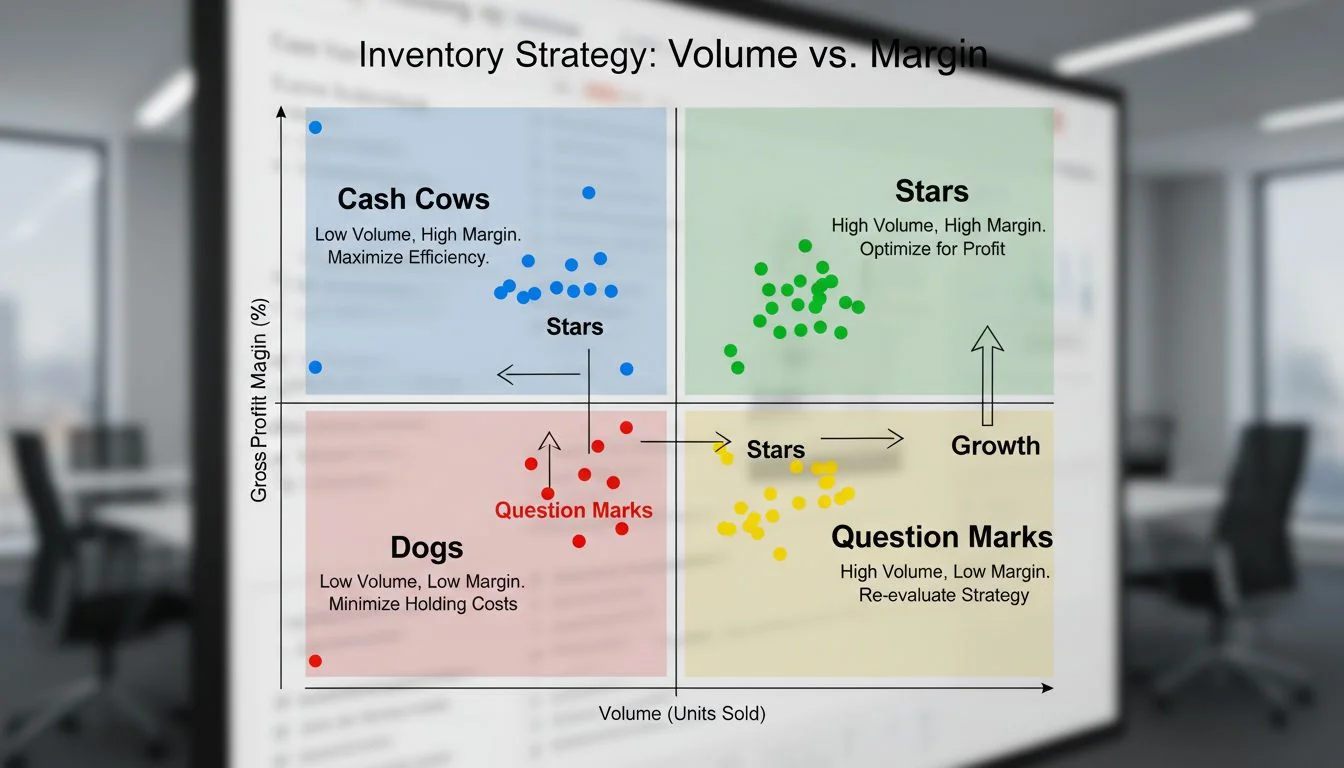

Portable units are the volume leaders, acting as steady "Cash Cows1" for your business, while wall-mounted units are the high-margin "Stars" that unlock specific niches like nurseries and commercial contracts. To maximize profitability in 2025, a successful inventory strategy requires a hybrid approach that leverages the strengths of both designs.

Many designers and business owners think they must choose just one path. They focus entirely on the popular floor models or try to be too unique with wall units. However, after years in the mold and trading industry, I have seen that the real magic happens when you understand the financial role of each product. Let's break down why you need to rethink your product mix.

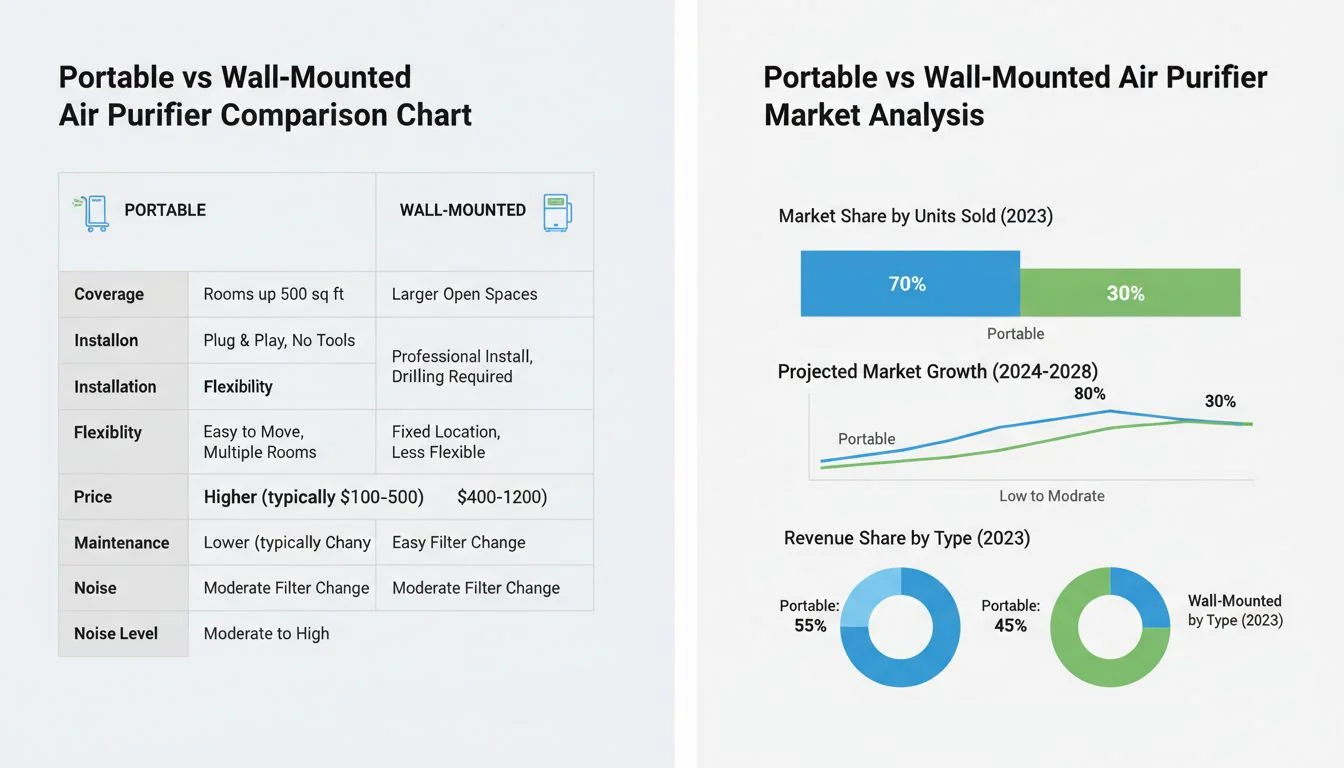

Portable air purifiers account for over 70% of total market volume due to ease of use.真

Market data consistently shows portable units dominate residential sales because they require no installation.

Wall-mounted units are only useful for hospitals and have no residential appeal.偽

Wall-mounted units are increasingly popular in residential nurseries and compact apartments due to safety and space-saving benefits.

Introduction: The Inventory Dilemma?

Deciding on your mold investment and inventory mix is the hardest part of product planning. If you get the balance wrong, you tie up capital in products that move too slowly.

The dilemma is choosing between high sales volume with lower margins or lower sales volume with much higher profit margins. Most businesses fail to optimize this mix, leaving significant revenue on the table by ignoring the unique benefits of a diversified product portfolio2.

In my early days working at the mold factory, I saw many clients make a common mistake. They would pour all their budget into one "perfect" design. Usually, this was a standard portable unit. They played it safe. While they sold units, their growth was flat because the competition for standard floor units is fierce.

On the other hand, I saw clients who tried to be too clever. They designed complex wall-mounted systems that were hard to install. They struggled to move volume. The "Inventory Dilemma" is not just about storage space; it is about cash flow management. You need products that turn over cash quickly to pay the bills. But you also need products that build real wealth through higher margins.

From a design perspective, this choice impacts everything. A portable unit needs a robust base and impact-resistant casing for moving around. A wall unit needs a lightweight design and a secure mounting plate. As a designer, you must understand the business case behind these engineering choices. You are not just designing a plastic shell; you are designing a revenue stream.

Diversifying product types reduces overall business risk.真

Having both high-volume and high-margin products protects cash flow if one market segment slows down.

Mold costs are identical for portable and wall-mounted units.偽

Wall-mounted units often require more complex tooling for mounting mechanisms and lighter, thinner wall sections.

The Case for Portable (Floor) Units: The "Volume" King?

Portable floor units are the default choice for most consumers entering the market. If you ignore this segment, you miss out on the vast majority of first-time buyers.

Portable units are your "Cash Cows" because they offer steady, predictable sales volume with a low barrier to entry for customers. They are essential for maintaining healthy cash flow and keeping your factory or production lines moving constantly.

When we talk about the "Volume vs. Margin" trade-off, portable units sit firmly on the volume side. In the B2B world, we call these "Cash Cows." These are the products that keep the lights on. They are easy to sell because customers understand them immediately. There is no installation required. The customer buys it, plugs it in, and it works.

From a manufacturing and mold design standpoint, these units are often more forgiving. You have more freedom with weight. You can use standard, cost-effective plastics because the unit sits on the floor. The internal components can be arranged vertically without worrying about the unit pulling away from a wall.

However, because they are easy to make and sell, the competition is high. This drives the price down. You will not make a huge profit on a single unit. Instead, you make your money on the sheer number of units you sell. For a designer like Jacky, this means the focus is on "design for manufacturing3" (DFM) to shave pennies off the production cost. Every gram of plastic saved on a high-volume product adds up to massive savings over a year. You need these units in your catalog to ensure you have the cash flow to fund more ambitious projects.

Comparison of Unit Types

| 特徴 | Portable (Floor) Units | 壁掛けユニット |

|---|---|---|

| Financial Role | Cash Cow (Volume) | Star (Margin/Growth) |

| Competition | 非常に高い | Low / Niche |

| インストール | Plug & Play | Requires Mounting |

| Primary Customer | General Residential | Parents, Schools, Hotels |

Portable units usually have higher profit margins than wall units.偽

Due to high competition and commoditization, portable units typically have thinner margins compared to specialized wall units.

Portable units are easier to ship logistically.真

They are often stackable and don't require specialized mounting hardware packages, simplifying packaging.

The Case for Wall-Mounted Units: The "Margin" & "Niche" Leader?

While floor units bring in the volume, wall-mounted units bring in the profit. If you want to grow your bottom line, you cannot rely on volume alone.

Wall-mounted units are "Stars" that command higher prices and dominate specific high-value niches like nurseries and commercial spaces. They solve specific pain points that floor units cannot, allowing you to charge a premium for the specialized design.

This is where the "Nursery" niche becomes a goldmine. I always advise my clients to look at the "New Parent" demographic. Parents are terrified of safety hazards. A heavy portable air purifier on the floor is a tipping risk for a toddler. It is also a tripping hazard. A wall-mounted unit removes this danger completely. It is out of reach and securely fastened. Because it solves a deep emotional fear (safety), parents are willing to pay a much higher price.

Furthermore, commercial contracts rely heavily on wall-mounts. If your distributor wants to sell to schools, hotels, or hospitals, they cannot win with floor units. A hotel does not want a portable unit that a guest can steal or trip over. A school needs clear walkways. By offering a wall-mounted option, you open up these massive B2B contract opportunities.

For a mold designer, this presents a fun challenge. You need to design for safety and aesthetics. The unit must look slim on the wall, not bulky. You have to calculate mold shrinkage carefully to ensure the mounting brackets fit perfectly every time. The plastic parts need to be lightweight yet rigid. This higher level of design difficulty is exactly why you can charge more. It is a specialized product for a specialized need.

Wall-mounted units are safer for toddlers.真

They eliminate tipping hazards and keep electrical cords out of reach of small children.

Hotels prefer portable units for flexibility.偽

Hotels prefer wall-mounted units to prevent theft, damage, and liability issues related to tripping.

The "Hybrid" Strategy: Why You Need Both?

The smartest businesses do not choose one or the other; they choose both. A complete product line captures the customer at different stages of their journey.

The "Hybrid" strategy positions you as a full-spectrum partner, allowing you to utilize the "Second Unit" upsell to increase Customer Lifetime Value (LTV). By offering both options, you can fill shipping containers more efficiently and satisfy diverse buyer needs.

Here is a strategy that increases Customer Lifetime Value (LTV): The "Second Unit" upsell. Imagine a customer buys a large floor unit for their living room. They love it. Six months later, they want clean air in their bedroom, but they have no floor space. That is when you pitch the wall unit. If you only sold floor units, you would lose that second sale. By having both, you keep the customer.

This also applies to sourcing and logistics. Many factories specialize in only one type. This is a headache for buyers. You should position yourself—or your manufacturing partner, like Hisoair—as a "One-Stop Shop." Hisoair is a great example of a "Full-Spectrum Partner." They can fill a container with a mix of floor and wall units.

This simplifies logistics for the buyer. Instead of managing two suppliers and two shipments, they get everything from one source. As a designer or a trader, if you can offer this mix, you become irreplaceable. You are not just selling a product; you are solving a supply chain problem4. You provide the volume product to pay the bills and the margin product to grow the profit, all in one shipment.

Upselling a second unit increases Customer Lifetime Value.真

Selling an additional product to an existing customer lowers acquisition costs and increases total revenue per user.

Sourcing from multiple factories simplifies logistics.偽

Consolidating orders with a 'One-Stop Shop' partner like Hisoair streamlines shipping and reduces administrative overhead.

結論

To succeed in 2025, do not choose between volume and margin; choose both. Use portable units for cash flow and wall-mounted units for high-profit niches like nurseries and commercial contracts.

References

-

Understanding Cash Cows can help you identify steady revenue streams in your product line. ↩

-

A diversified portfolio reduces risk and enhances revenue potential. ↩

-

DFM principles can significantly lower production costs and improve efficiency. ↩

-

Identifying supply chain problems can help streamline operations and reduce costs. ↩