呼吸をするたびに、安全への一歩を踏み出したような気分になる病院を想像してみてほしい。それが ヘパ フィルターがある!

ヘパ フィルター製造は、空気の質を確保する役割、安全基準の遵守、特定の用途にフィルターをカスタマイズする能力により、OEMにとって不可欠です。これらのフィルターは有害な粒子を捕捉するため、重要な環境では不可欠です。

しかし、そのよく知られた効率性の先には、複雑な製造の世界がある。このフィルターを際立たせている技術やカスタマイズ・オプションについて、私と一緒に深く掘り下げていきましょう。

HEPAフィルターは、0.3ミクロン以上の粒子を99.97%捕集します。真

この効率はHEPAフィルターの標準であり、高い空気品質を保証する。

どのように ヘパ 健康規制の遵守を保証するフィルター

ヘパ フィルターは、厳しい衛生規制を満たし、さまざまな産業で清潔で安全な環境を提供する上で重要な役割を果たしている。

ヘパ フィルターは、直径0.3ミクロンの浮遊粒子を99.97%以上捕集することで衛生規制に準拠し、清浄な空気品質を保証します。この性能により、病院や研究室など、厳しい空気清浄基準が求められる環境には欠かせないものとなっています。

理解する ヘパ 規格と規則

ヘパ フィルターは、健康と安全を守るために効果的であることを保証する厳しい基準を満たさなければならない。フィルターの効率は ヘパ フィルターが微小粒子を捕捉することは、米国環境保護庁(EPA)や世界保健機関(WHO)などの当局が定めた厳しい規制に準拠するための重要な要素である。準拠するためには、これらのフィルターは0.3ミクロンの空気中の微粒子を99.97%捕捉する能力を実証しなければなりません。この仕様は、空気中の病原体を最小限に抑えなければならない病院などの環境では非常に重要です。

役割 ヘパ 重要な環境におけるフィルター

ヘルスケアや医薬品のように、無菌環境を維持することが重要な分野では、 ヘパ フィルターは、HVACシステムに不可欠なコンポーネントです。患者の安全や製品の完全性を損なう可能性のある汚染物質が空気中にないことを保証します。例えば、手術室やクリーンルームなどです、 ヘパ フィルターは、潜在的に有害な粒子をろ過することで、厳しい清浄基準を満たす環境を維持するのに役立ちます。

特定の規制ニーズに合わせたカスタマイズ

カスタマイズ ヘパ フィルターを使用することで、さまざまな用途で特定の規制に準拠することができます。HisoAirのようなメーカーは カスタマイズ ヘパ ソリューション1 は、OEMのユニークな要件を満たすために、各フィルターが意図された環境の規制要求に適合することを保証します。これには、微生物利用機能を備えたフィルターの設計や、リサイクルされたコーヒー粉のような持続可能な素材の統合も含まれます。

革新的な素材と技術

の進歩 ヘパ フィルター素材と技術は、衛生規制の遵守に大きく貢献します。高効率のメディア素材は、ろ過効果を維持しながら気流抵抗を減らし、エネルギー効率を損なうことなく性能を向上させることができる。現在では、フィルター表面でのバクテリアの繁殖を防ぐ抗菌コーティングを取り入れるメーカーもあり、フィルターが提供できる安全基準をさらに高めている。

これらの点を理解することで、OEMは次のような選択をすることができる。 ヘパ 現行の健康規制を遵守するだけでなく、将来の変化や技術の進歩にも対応できるフィルター。

HEPAフィルターは、0.3ミクロンの粒子を99.97%捕集します。真

HEPAフィルターは、0.3ミクロンの浮遊粒子を少なくとも99.97%捕捉するように設計されています。

HEPAフィルターは病院では使われていない。偽

HEPAフィルターは、有害な粒子をろ過して無菌環境を維持するために、病院では欠かせないものだ。

どのようなカスタマイズが可能か OEM ヘパ フィルター?

OEMには独自のニーズがあり、特に以下のような場合には、そのニーズに合わせたソリューションが必要となる。 ヘパ フィルターカスタマイズ可能なオプション OEM ヘパ フィルターがある。

OEM ヘパ フィルタは、設計、材料、効率、およびアプリケーション固有の機能における広範なカスタマイズを提供し、多様な産業ニーズに対応します。

多様な用途に合わせたデザイン

OEMは、カスタマイズすることができます。 デザイン2 の ヘパ フィルターは、家庭用空気清浄機、HVACシステム、産業用機器など、特定の用途に適合します。このカスタマイズには、フィルターのサイズ、形状、枠の材質などを調整し、最終使用環境との適合性を確保することが含まれます。

| デザイン・エレメント | カスタマイズ・オプション |

|---|---|

| サイズと形状 | 長方形、円形、またはカスタム寸法 |

| フレーム素材 | アルミニウム、プラスチック、亜鉛メッキスチール |

| シーラント&ガスケット | フォーム、ゴム、シリコーン |

性能向上のための素材選択

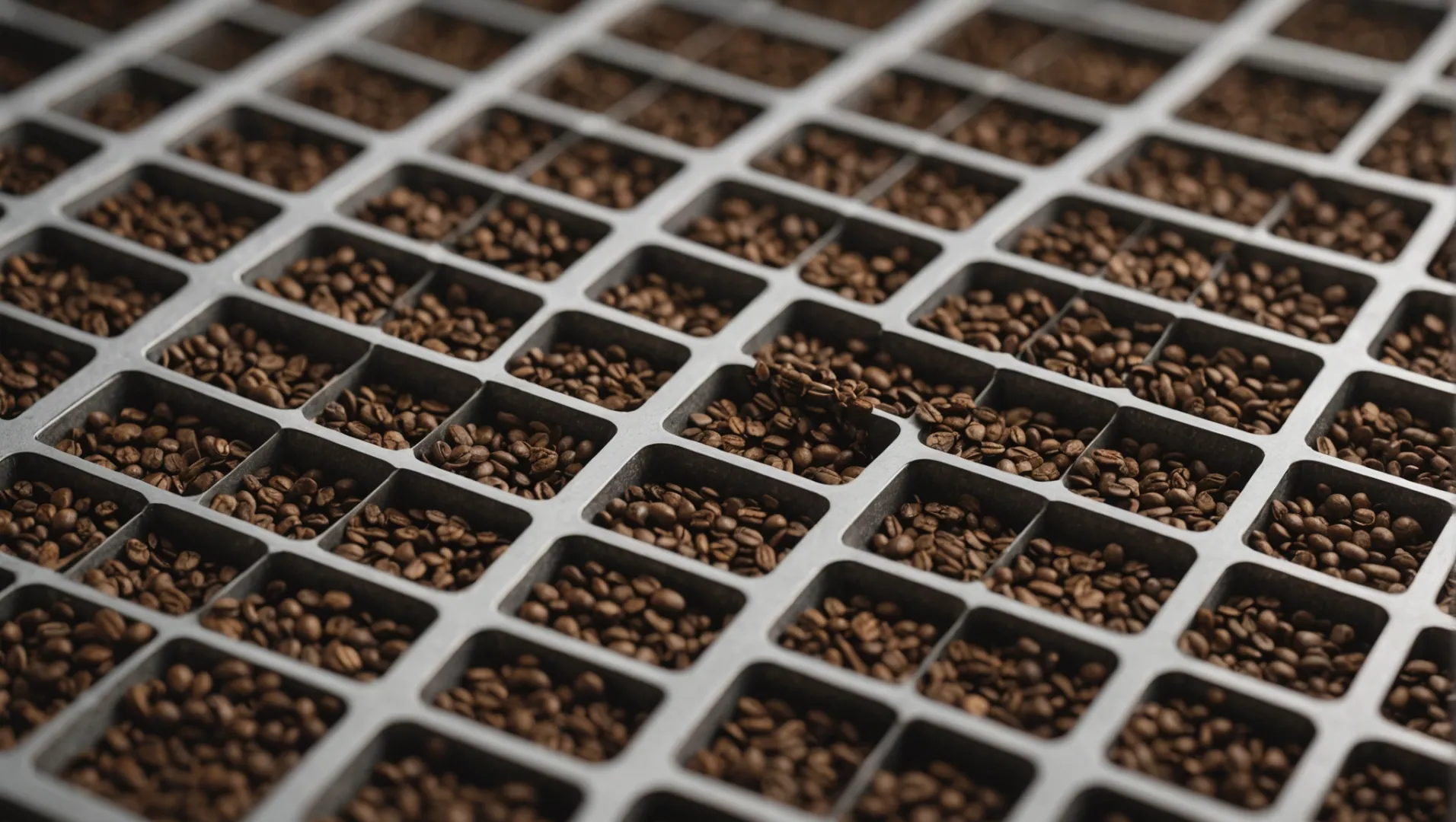

メーカーは、カスタマイズのためのオプションを提供している。 材料3 で使用される。 ヘパ メディア。これには、低抵抗で粒子捕捉率を高める高効率素材が含まれる。革新的な選択肢の中には、リサイクルされたコーヒーの粉塵を媒体に組み込むことで、従来の活性炭に代わる持続可能なソリューションを提供するものもあります。

特殊用途のための高度な機能

医療現場や産業現場など、特殊な用途を必要とするOEM向け、 ヘパ フィルターは、微生物コーティングやその他の技術によって強化することができる。これらの技術革新は、有害な病原体の捕獲と中和に役立ち、厳しい衛生・安全基準の遵守を保証します。

- 微生物コーティング:フィルター表面の細菌やウイルスを抑制する。

- 抗菌メディア:微生物を殺す、または不活性化する薬剤を埋め込んだもの。

効率と抵抗のバランス

フィルター効率と気流抵抗のバランスをカスタマイズすることは、さまざまな環境で性能を最適化するために非常に重要です。このバランスにより、最大限のろ過が達成される一方で、エネルギー消費は管理可能なままとなります。

さらに詳しく 効率と抵抗4 様々な業界において、これらの要因がフィルターの性能にどのような影響を与えるかを理解するために、バランシングを行っている。

OEMのHEPAフィルターは、特定の用途に合わせてカスタマイズすることができます。真

OEMは、独自のニーズに合わせてサイズ、形状、素材を調整することができる。

HEPAフィルターに抗菌機能を含めることはできない。偽

HEPAフィルターには抗菌メディアや微生物コーティングを施すことができる。

どのような進歩があるか ヘパ テクノロジーが業界を形作る?

の画期的な進歩をご覧ください。 ヘパ 空気ろ過に変革をもたらし、業界の新たな基準を打ち立てる技術である。

最近の進歩 ヘパ テクノロジーは、微生物フィルター、持続可能な素材、効率の向上に重点を置いている。これらの技術革新は、より多くの汚染物質を捕捉し、抵抗を減らし、環境に優しいやり方を促進することで、空気の質を向上させる。

微生物入り ヘパ フィルター

における最も重要な進歩のひとつは ヘパ テクノロジーは、フィルター・メディアに抗菌剤を組み込むことです。この技術革新により、フィルターがバクテリアやウイルスを捕捉・中和する能力が強化され、ヘルスケアやクリーンルームの用途に理想的なものとなっている。

このような薬剤を組み込むことで、フィルター自体で微生物が繁殖するリスクを減らし、寿命と効率を延ばすことができる。例えば ヒソエア5 カスタマイズされた ヘパ さまざまな用途に合わせて調整された微生物機能を持つフィルターが、安全性と性能の両方を向上させる。

高効率、低抵抗メディア

もうひとつの重要な開発は、高効率でありながら低抵抗の媒体の開発である。伝統的な ヘパ フィルターは、エネルギー消費とシステム性能に影響する気流抵抗に関連する課題にしばしば直面していた。しかし、新しいメディア素材は、圧力損失を減らしながらより大きな気流を可能にし、エネルギー使用量を最適化しながら優れた濾過効果を維持する。

このような改善により、OEMの導入が可能になった。 ヘパ 効率性を犠牲にすることなく、より広範なデバイスでフィルターを使用できる。

持続可能な素材 ヘパ 製造業

持続可能性は、空気ろ過を含む多くの産業で重要な焦点となっている。最近の ヘパ 技術では、従来の活性炭に代わって、リサイクル・コーヒーの粉のような環境に優しい素材を消臭に使用している。これは再生不可能な資源への依存を減らすだけでなく、製品の持続可能性を高める。

たとえば、リサイクル素材を使用することは、廃棄物の削減や環境に配慮した製造方法の推進を目指す世界的なイニシアティブに合致する。

多様なアプリケーションのためのカスタマイズされたソリューション

カスタマイズ ヘパ フィルター製造により、OEMは家庭用空気清浄機、工業用環境、医療環境など、特定のニーズに対応することができます。オーダーメイドのソリューションを提供することで、メーカーはさまざまな分野の規制基準や性能要件を満たすことができます。

カスタマイズ能力は、サイズや形状にとどまらず、独自の環境条件や汚染問題に対応する特殊な素材や技術を選択することも含まれる。

これらの進歩は、空気の質を向上させるだけでなく、さまざまな業界の進化する需要に適応することへのコミットメントを示しています。これらの革新的な技術を取り入れることで、OEMは自社の製品が空気ろ過ソリューションの最前線に立ち続けることを確実にすることができる。

HEPAフィルターは現在、消臭にリサイクルコーヒーの粉を使用している。真

リサイクルされたコーヒーの粉は、従来の素材に代わる環境に優しい素材である。

微生物入りHEPAフィルターはバクテリアを中和することはできない。偽

これらのフィルターは、バクテリアを捕捉して中和するよう特別に設計されている。

持続可能な開発はなぜ重要なのか ヘパ フィルター製造?

サステイナビリティは産業を変革し ヘパ フィルター製造も例外ではありません。この分野で持続可能な実践が重要な理由をご覧ください。

持続可能な開発 ヘパ フィルター製造は、環境への影響を低減し、製品イノベーションを強化し、環境に優しいソリューションを求める消費者の需要に応えるために重要です。リサイクル素材を使用し、エネルギー効率の高いプロセスを採用することで、メーカーは性能を損なうことなく、より環境に優しい製品を作ることができます。

伝統的製造業が環境に与える影響

トラディショナル ヘパ フィルター製造には、重大な環境破壊につながる可能性のあるプロセスが含まれる。これには、再生不可能な資源の消費と、製造中の廃棄物の発生が含まれる。持続可能な開発に向けてシフトすることで、製造業者はこれらの影響を軽減し、より健全な地球に貢献することができる。

革新的な素材 ヘパ フィルター

持続可能性における最もエキサイティングな進歩のひとつ ヘパ フィルター製造には 再生材料6.例えば、リサイクルされたコーヒーの粉を ヘパ メディアは、活性炭に代わる有効な選択肢を提供します。この技術革新は、廃棄物を減らすだけでなく、フィルターの臭気を効果的に中和する能力を維持します。

環境に優しい製品に対する消費者の需要に応える

環境問題への意識が高まるにつれ、消費者はますます環境に優しい製品を求めるようになっている。持続可能な取り組みを取り入れることで ヘパ フィルター・メーカーはこの需要に応えることができ、環境意識の高い顧客にとって自社製品がより魅力的なものになる。このシフトは、新たな市場機会を開くだけでなく、ブランドの評判を高める。

エネルギー効率の高い製造プロセスの利点

エネルギー効率は持続可能な製造業の要である。省エネ技術を ヘパ フィルター生産は、カーボンフットプリントと操業コストを大幅に削減することができる。このような実践により、製造から最終使用まで、製品のライフサイクル全体を通じて環境上のメリットがもたらされます。

イノベーションにおける持続可能な開発の役割

持続可能性とは、単に害を減らすだけではありません。持続可能な開発は、新素材や新技術の探求を促し、より高性能で長持ちするフィルターへと導きます。この継続的な改善サイクルは、急速に進化する市場で競争力を維持するために不可欠です。

サステイナブルHEPAフィルターは、リサイクルされたコーヒーの粉を使用しています。真

活性炭の代替品として、リサイクルされたコーヒー粉が使用されている。

伝統的なHEPA製造は環境への害を低減する。偽

従来のプロセスは再生不可能な資源を消費し、廃棄物を発生させる。

結論

ヘパ フィルターは、重要な環境における空気品質と安全性の維持に不可欠です。その重要性とカスタマイズオプションを把握することで、OEMは製品の信頼性とコンプライアンスを高めることができます。高度な ヘパ 最適なパフォーマンスのためのソリューション。

-

コンプライアンスに合わせたHEPAフィルターソリューションを提供します:オーダーメイドの高性能ソリューション:お客様のニーズに合わせてカスタマイズされたプレミアム空気清浄機を提供することで、優れた空気品質を確保し、お客様のご要望を上回る性能を発揮します。 ↩

-

特定の用途に適応可能な様々な設計要素についてご覧ください:お客様のカスタムHEPAフィルターは、AutoCADとSolidWorksを使用して設計され、3D流体力学的画像が作成されます。その後、試作品を作成します。 ↩

-

性能と持続可能性を高める素材をご覧ください:カスタマイズサイズのHEPAフィルターも承ります。カスタム範囲。効率, H10からH14、U15まで。フレーム材質: 金属またはパーティクルボードフィルター素材 ↩

-

濾過効率と通気抵抗のトレードオフを理解する..:HEPAに似たフィルターは一般的に効率が低く、2.5ミクロン程度の粒子を捕捉しますが、これは、空気中の微粒子を除去する効果が低い可能性があります。 ↩

-

抗菌特性がフィルター効率と寿命をどのように向上させるかをご覧ください:抗菌・抗ウイルスHEPAフィルター。モデルF060.フィルター構成:抗菌・抗ウイルスHEPA+ブラックカードペーパーフレーム+T5シーリングストリップ。 ↩

-

リサイクル素材がいかに環境に優しく、フィルター性能を高めるかをご覧ください:briivエアフィルターは、バイオプラスチックや段ボール、ガラスなどのリサイクル可能な素材から完全に作られています。 ↩