エアフィルターのカスタマイズをお考えですか?スケジュールは混乱しているかもしれません!私はそのプロセスについて、いくつかの洞察を発見しました。

エアフィルターのカスタマイズには通常2~4週間かかります。この期間は、フィルターの複雑さと製造者のスキルの2つの要因に左右されます。よりシンプルなデザインであれば、2週間以内で納品されることが多い。一方、HEPAフィルターのような複雑な設計の場合は、さらに時間がかかることがあります。厳密なテストと規格への準拠がこの期間を長くします。メーカーとの具体的なニーズについてのコミュニケーションは、本当に役に立ちます。その結果、プロセスがスムーズに進むことが非常に多いのです。

初めてエアフィルターのカスタマイズを始めたとき、少し圧倒された気がした。通常の期間は2週間から4週間。HVACフィルターのようなシンプルなデザインであれば、2週間以内に届くかもしれない。しかし、HEPAフィルターのような複雑なフィルターになると、非常に厳しいテストが要求されるため、時間がかかることもある。私は最初のカスタムフィルターを心配しながら待ったことを覚えている。永遠に続くように感じた!その忍耐は報われました。品質と安心感は1分1秒を争う価値がありました。

エアフィルターのカスタマイズには通常2~4週間かかる。真

エアフィルターのカスタマイズ期間は一般的に2~4週間で、設計の複雑さとメーカーの効率に影響される。

HEPAフィルターは、シンプルなデザインに比べてカスタマイズに時間がかからない。偽

HEPAフィルターはより厳密な試験を必要とすることが多く、単純なエアフィルター設計に比べてカスタマイズに時間がかかる。

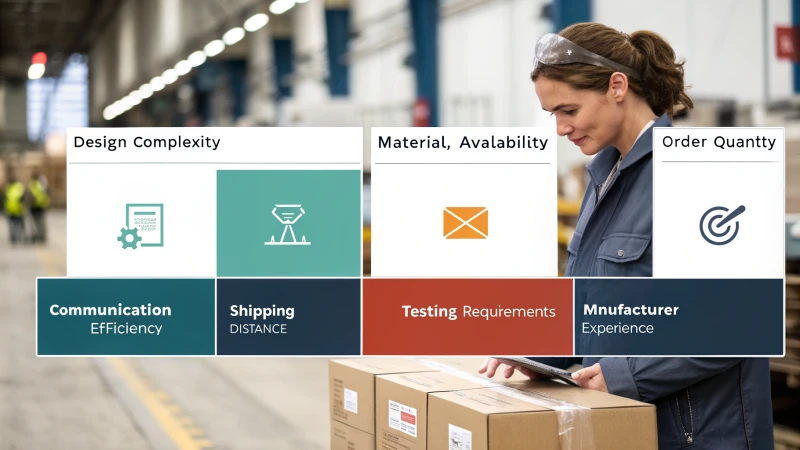

カスタマイズのタイムラインに影響を与える要因とは?

製品をパーソナライズするために何が必要なのか、考えたことはあるだろうか。そのプロセスは難しく思えるかもしれません。ここでは、それを簡単に説明します。カスタマイズの旅に影響を与える主な要因を検証してみましょう。

カスタマイズにかかる時間は、デザインの難易度によって異なる。材料の在庫状況も影響する。オーダーのアイテム数も重要です。コミュニケーションは大きな役割を果たす。配送距離もタイミングに影響する。テストが必要な場合、時間がかかることがあります。メーカーの経験も要因のひとつです。これらの要素を知ることは、何を期待するかを管理するのに役立ちます。この知識はプロセスの改善に大いに役立ちます。

カスタマイズのタイムラインを理解する

カスタマイズ・プロジェクトを検討する際には、タイムラインに影響を与える様々な要因を理解することが不可欠です。ここでは、考慮すべき重要な要素をいくつかご紹介します:

-

デザインの複雑さ

デザインが複雑であればあるほど、完成までに時間がかかるかもしれません。例えば、あるバッグにシンプルなロゴを入れたいと思ったことがある。基本的なデザインは簡単そうに見えたが、細かいパターンを加えることで進行が遅くなった。シンプルなデザインはすぐに仕上がりますが、複雑なデザインはより多くの調整と承認が必要です。デザインの段階でプロジェクト全体の方向性が決まるので、これは非常に重要です。 -

材料の入手可能性

プロジェクトを始めたものの、材料が手に入らなかったという経験はないだろうか。材料不足は生産を大幅に遅らせる可能性があります。以下のことをサプライヤーに確認することが重要です。 材料の入手可能性1 を早い段階から開始する必要がある。環境に優しい生地など、特定の素材が必要な場合は、リードタイムが大幅に延びる可能性があります。 -

注文数量

オーダーサイズは生産スピードに大きく影響します。少量の注文は、生産スケジューリングとリソースの割り当てにより、大量の注文に比べて短納期になることがよくあります。概要は以下の通りです:注文数量 予定スケジュール 1~50台 1~2週間 51~200台 2~4週間 201ユニット以上 4週間以上 -

コミュニケーション

このプロセスでは、コミュニケーションが非常に重要であることがわかる!メーカーとの効率的なコミュニケーションは、プロセスを迅速化します。フィードバックや承認が遅れると、スケジュールが大幅に延びる可能性があります。最初から明確なコミュニケーション・チャンネルを確立することで、プロセスがスムーズに流れるようになります。 -

輸送距離

配送を心待ちにしていたのに、遠くから届いていることに気づいたことはありませんか?お客様の配送先住所と製造元の位置関係は、商品の到着の早さに影響します。国際配送の場合、通関の関係でさらに遅延が生じたり、輸送時間が長くなったりすることがあります。 -

テストと品質保証

HVACフィルターのような特定の用途を含むプロジェクトでは、品質テストが不可欠となる。カスタム製品は、特にHEPAフィルターのような高効率ユニット向けの場合、品質保証試験を通過する必要があることが多い。堅牢な試験設備を持つメーカーは、品質基準を維持しながらタイムリーな納品を実現するのに役立ちます。 資格2. -

メーカー経験

経験豊富なメーカーと協力することで、カスタマイズの期間を大幅に短縮することができます。プロセスや問題点に関する彼らの知識は非常に貴重です。例えば、HisoAirのような会社は、空気浄化技術において20年以上の実績を誇り、効率的なプロジェクト処理を保証します。

これらの要素を考慮することで、プロジェクトのカスタマイズ・スケジュールに関する期待値をよりよく理解し、管理することができます!積極的なプランニングとメーカーとの明確なコミュニケーションが、スムーズなオペレーションとタイムリーな納品につながることを覚えておいてください。

複雑なデザインは、単純なものよりも最終的に仕上げるのに時間がかかるものだ。真

デザインの複雑さは、承認や調整に必要な時間に直接影響するため、複雑なデザインは単純なオプションよりも完成に時間がかかる。

小口注文の場合、より迅速な納期が保証されます。真

少量の注文は、大量の注文に比べてリソースの割り当てが少なく、スケジューリングが合理化されているため、通常、納期が短縮される。

カスタム・エア・フィルターの品質を保証するには?

カスタム・エアフィルターは品質がとても重要。私はこの事実を知った。このことを理解することで、私は最良の選択肢を選ぶことができる。あなたも同じようにしてください。

一流のカスタム・エアフィルターなら、経験豊富なメーカーを選ぼう。仕様をよく知ること。開発段階で明確に話し合う。厳しい品質チェックを行う。良いフィルターには非常に厳しい監視が必要です。

カスタムエアフィルターの品質

カスタムエアフィルターの品質を確保するためには、いくつかの重要な要素を考慮する必要があり、それぞれがフィルターの全体的な性能と効果に寄与します。以下に、いくつかの重要な点を挙げる:

フィルターの仕様を理解する

製造工程に入る前に、フィルターが満たすべき仕様を理解することが重要です。HVACシステムやクリーンルームなど、用途によって必要とされるろ過レベルや基準は異なります。

- HVACフィルター:通常、製造はより単純で迅速である。以下のようなものがある。 MERV評価3 その効率を定義するものである。

- HEPAフィルター:デリケートな環境では、しばしば高効率フィルターが要求される。HEPA 14のような)厳しい基準を満たす必要がある。

適切なメーカーの選択

カスタムエアフィルターの品質を確保するには、メーカーの選択が重要な役割を果たす。以下は、考慮すべきいくつかのポイントである:

| 基準 | 重要性 |

|---|---|

| 経験 | 実績のあるメーカーであれば、複雑な要求にもうまく対応できる。 |

| 技術的専門知識 | フィルター技術に関する高度な知識を持っていることを確認する。 |

| 品質認証 | ISO認証やその他の業界標準を探す。 |

ヒソエアのような経験豊富なメーカーと仕事をすることは、最終製品の品質に大きな影響を与えます。

開発中のコミュニケーション

お客様のご要望を確実に満たすためには、メーカーとの効果的なコミュニケーションが不可欠です。主な慣行は以下の通り:

- 定期的なアップデート:頻繁にチェックインすることで、懸念事項を早期に解決することができる。

- 詳細仕様:誤解を最小限にするため、包括的な要件を提供する。

品質管理プロセス

フィルターの品質を維持するには、しっかりとした品質管理プロセスが不可欠です。以下は、メーカーが採用している可能性のあるいくつかの方法である:

- 社内テスト:メーカーが健全な試験所を持っていることを確認すること。

- 第三者試験:フィルター性能の追加検証のため、外部ラボの関与を検討する。

品質保証の方法には次のようなものがある。 試験プロトコル4 要求される基準を満たすために、様々なフィルタータイプに対応する。

素材選択の重要性

フィルターの効果を高めるには、適切な素材を選ぶことが重要です。考慮すべき要素

- メディアの種類:異なるフィルターメディア(ガラス繊維、合成繊維)は、様々な効率と寿命を提供します。

- フレーム素材:耐久性のあるフレームは、フィルターの寿命と構造的完全性を高めることができる。

インストール手順

適切な取り付けは、製造品質と同様に重要です。正しい手順に従うことで、フィルターが意図したとおりに機能し、長期間にわたって性能を維持することができます。考えてみてください:

- メーカーガイドライン:常にメーカーが提供する特定の取り付け説明書を遵守してください。

- 定期メンテナンス:空気の質を維持するために、定期的な点検と交換を予定する。

結論

これらの重要な領域に焦点を当てることで、カスタムエアフィルターの品質保証を大幅に強化し、性能の向上と環境の空気質の改善につなげることができます。エアフィルターの品質保証についてさらに詳しくお知りになりたい方は、以下をご覧ください。 業界のベストプラクティス5.共に賢い選択をすることで、呼吸を楽にすることができる!

HEPAフィルターは厳しい性能基準を満たさなければならない。真

HEPAフィルターは、敏感な環境で効果的な空気ろ過を行うために、HEPA 14のような特定の効率基準を満たすことが要求される。

エアフィルターの性能を維持するためには、定期的なメンテナンスは不要である。偽

エアフィルターの性能と空気の質を長期間にわたって最適な状態に保つためには、点検や交換を含む定期的なメンテナンスが重要です。

カスタマイズに時間がかかるエアフィルターとは?

エアフィルターの交換に時間がかかるものがあるのはなぜか、考えたことはありますか?私はある!エアフィルターの世界を覗いてみよう。エアフィルターの種類によって、交換に手間がかかるものもあるのだ。

HEPAフィルターやULPAフィルターなど、一部のエアフィルターは通常、カスタマイズに時間を要する。複雑な設計で、厳しい性能規定を満たさなければならないからです。アプリケーションの種類は、カスタマイズにかかる時間に大きく影響します。このプロセスでは、メーカーの経験も非常に重要です。

カスタム・エアフィルターについて

カスタム・エアフィルターはスーツと同じで、完璧にフィットする必要があります!このプロセスには、様々な要因によって2週間から4週間かかる場合があります。ご説明しましょう。

カスタマイズ時間に影響を与える要因

| ファクター | カスタマイズ時間への影響 | 例 |

|---|---|---|

| アプリケーションの種類 | 変動あり(2~4週間) | HVACとクリーンルームの比較 |

| コミュニケーション | 時間を短くすることも長くすることもできる | 迅速なフィードバックが必要 |

| テスト | さらに時間がかかる場合がある | 第三者機関によるテスト |

| メーカーの経験 | 効率化のために重要なこと | ヒソエアの専門知識 |

-

アプリケーションの種類:

- HVACフィルターは通常、シンプルなデザインだ。私は2週間以内に空調用フィルターを用意したことがある。工場はすでにデザインを持っていた。

- しかし、クリーンルーム用の高効率フィルターには、より厳しい要件がある。HEPAフィルターやULPAフィルターは、特定の基準により、より多くの時間を必要とする。

-

メーカーとのコミュニケーション:

- 明確なコミュニケーションは本当に重要だ。私のことを理解してくれるメーカーと仕事をすると、物事が早く進むことがよくあります。私の要求に精通していることは本当に助けになります。

-

試験要件:

- テストはしばしば遅れの原因となる。フィルターを規格に適合させるには、厳しいテストに合格しなければならない。ある時、メーカーに良い研究施設がなかったため、長い間待たされたことがある。私たちは第三者のテストに頼りました。

-

メーカーの経験:

一般的なカスタム・エア・フィルターの種類

- HEPAフィルター:

これらの高効率フィルターはゴールドスタンダードのようなものだ。厳格な要件のため、慎重な設計と多くのテストが必要だ。 - ULPAフィルター:

超低透過フィルターはさらに難しい。それをカスタマイズするには、特定の用途と、通常は多くの研究室での作業が必要になる。

結論は?

エアフィルターを研究する中で、それぞれのタイプにユニークな要求とニーズがあることに気づいた。自分のニーズに合ったフィルターを選ぶための詳細を知りたい方は、以下をご覧ください。 本ガイド7.これらの違いを理解することで、後で時間とトラブルを避けることができる!

HEPAフィルターは、HVACフィルターよりもカスタマイズに時間がかかる。真

HEPAフィルターには厳しい性能基準があるため、HVACフィルターのシンプルな設計に比べ、カスタマイズに時間がかかる。

メーカーとのコミュニケーションは、カスタマイズの時間に影響を与えない。偽

メーカーとの効果的なコミュニケーションは、この主張とは逆に、カスタマイズ・プロセスを大幅に早めることができる。

なぜカスタム・フィルターの経験豊富なメーカーを信頼すべきなのか?

カスタム・フィルターの適切なメーカーを選ぶことは重要です。この選択には経験が重要な役割を果たします。効果的なろ過ソリューションにベテランの専門家が欠かせない理由をご案内します。

カスタムフィルターに経験豊富なメーカーを選ぶことは、品質の向上につながります。彼らの専門知識は、業界標準を満たすのに大いに役立ちます。お客様のニーズにぴったり合ったソリューションを提供してくれます。この決断は、長期的なコスト削減にもつながります。フィルターはより良く機能し、より長持ちします。ろ過システムの性能と信頼性が向上します。

フィルター製造における経験の重要性を理解する

初めてカスタムフィルターの世界に足を踏み入れたときのことを覚えている。多くの選択肢に圧倒された。他の多くの人たちと同じように、安いメーカーを選べばお金を節約できると思っていた。しかし、経験が非常に重要であることを私は知らなかった。単にフィルターを手に入れるだけでなく、そのフィルターが厳しい要件や業界標準を満たしていることを確認することが重要なのです。経験豊富なメーカーは、さまざまな用途を熟知しています。 HEPAフィルター クリーンルームのための彼らは、効率と信頼性を提供する具体的な設計と素材を理解しています。

彼らが提供するのは、単なる製品ではありません。彼らは、高水準のアプリケーションに不可欠な規制遵守や試験手順に関する見識を提供してくれる。私はこのことを苦労して学んだ。ガイダンスの欠如が、私にとってはコストのかかるミスにつながったのです。

さらに驚かされたのは、サプライヤーや試験所との確立された関係が、そのプロセスでいかに役割を果たしているかということだった。良好なつながりは、円滑なコミュニケーションと迅速な納品につながる。フィルターの種類に基づくリードタイムについて、私が発見した興味深いことがある:

| フィルタータイプ | 一般的なリードタイム | メーカー経験の重要性 |

|---|---|---|

| HVACフィルター | 2週間 | 中程度 |

| HEPAフィルター | 4週間以上 | 高い |

| ULPAフィルター | 4週間以上 | 非常に高い |

品質保証とテスト

経験豊富なメーカーは通常、強力な品質保証プロセスを持っている。私自身の旅の中で、社内にラボを持つことの重要性に気づきました。フィルターの効率と、以下のような規格への準拠をテストする ISO 168908 が不可欠だ。それがなければ、第三者のテストに頼ることになり、本当に遅延を引き起こす可能性がある。

彼らの経験は、設計段階の早い段階で潜在的な問題を発見するのに役立ちます。この早期対応により、後々のフィルター故障という悪夢からお客様を救うことができます。彼らは、ライフサイクルを通してろ過システムの完全性を維持するためのベストプラクティスを提供してくれます。もっと早く知っていればよかった。

カスタマイズ機能

カスタムフィルターが必要になったとき、単に個人的な選択だけでなく、アプリケーションが本当に必要としているものは何かということがわかりました。経験豊富なメーカーの存在は非常に貴重です。彼らは独自の仕様に合わせたソリューションを提供し、経験の浅い競合他社では手に入らない素材、サイズ、デザインを提案してくれます。

例えば、私はある企業のプロジェクトに携わった。 データセンター.特殊な素材がエアフローを最適化し、微粒子を効果的にろ過した。知識豊富なパートナーがいることで、性能と費用対効果の両方が向上しました。

長期的な費用対効果

当初、私は初期費用を節約するために経験の浅いメーカーに誘惑された。しかし、その判断は裏目に出た!貧弱な設計のフィルターでは、頻繁に交換や修理が必要で、あっという間に費用がかさんでしまったのだ。経験豊富な ヒソエア9 は、こうした落とし穴を回避するのに役立つ。彼らは初日から高品質で耐久性のある製品を提供する。

結論として、経験豊富なメーカーを選ぶことは長期的な利益をもたらします。カスタムフィルターの品質が向上し、業界標準への準拠が保証され、ろ過システム全体の効率が向上します。この決断は単なるフィルターへの投資ではなく、短期的な節約をはるかに上回る安心への投資なのです。

経験豊富なメーカーが高いフィルター効率を保証します。真

特にHEPAフィルターのような重要な用途では、設計と材料に関する彼らの知識が優れた性能につながっている。

経験の浅いメーカーを選ぶことは、長期的なコスト削減につながる。偽

その結果、頻繁な交換や修理のために運用コストが高くなり、当初の節約効果がなくなってしまうことがよくある。

結論

カスタムエアフィルターのカスタマイズは、複雑さ、素材、メーカーとのコミュニケーションによって異なりますが、通常2~4週間かかります。経験豊富なメーカーが品質と納期を保証します。

-

カスタマイズのタイムラインに関する洞察を深め、注文プロセスを最適化して効率を高める方法を学びましょう。 ↩

-

主要な影響要因を理解することにより、カスタマイズされた製品をタイムリーに納品するための知識を深める。 ↩

-

カスタムエアフィルターの高品質基準を維持するためのベストプラクティスと専門家の見識をご覧ください。 ↩

-

最高品質の製品を保証するために、信頼できるエアフィルターメーカーを選ぶための重要な基準について学んでください。 ↩

-

性能を保証するカスタムエアフィルターの効果的な取り付けとメンテナンスのための詳細なガイドラインをご覧ください。 ↩

-

このリンクでは、様々なエアフィルターの種類とそのカスタマイズプロセスについて詳しく説明しています。 ↩

-

この資料では、エアフィルターのカスタマイズのスケジュールに影響を与える要因についての洞察を提供し、お客様の選択肢をよりよく理解するのに役立ちます。 ↩

-

このリンクをクリックすると、エアフィルターに熟練したメーカーを選ぶ利点についての詳細な洞察が得られ、品質保証についての理解が深まります。 ↩

-

カスタマイズ・オプションがメーカーによってどのように異なるのか、またなぜ経験が重要なのかについては、このリンクをご覧いただきたい。 ↩