In today’s commercial landscape, indoor air quality (IAQ) has become a critical health and productivity factor. Whether you operate an office, a production shop floor, or a public venue, a high-performance air-purification system can protect employee wellbeing and drive efficiency. Yet with so many technologies on the market, decision-makers often face a dilemma: should they specify High-Efficiency Particulate Air (HEPA) filtration, activated-carbon filtration—or both?

This paper unpacks how the two dominant technologies work, where each excels, and why leading enterprises are increasingly adopting hybrid solutions to address modern IAQ challenges.

- Why do some purifiers remove dust but leave lingering odours?

- Does your facility struggle with both particulate and gaseous contaminants?

- How can you specify a system that reliably captures ultrafine particles そして harmful gases?

The answers lie in understanding the fundamental differences between HEPA and activated-carbon filtration.

What Is HEPA Filtration and How Does It Work?

High-Efficiency Particulate Air (HEPA) filters were developed during World War II to trap radioactive aerosols. A genuine HEPA filter must remove 99.97 % of particles measuring 0.3 µm—the Most Penetrating Particle Size (MPPS).

Constructed from densely interlaced fibres (typically glass fibre or polypropylene–polyester blends), a HEPA medium forms a labyrinth that captures particles through four concurrent mechanisms:

- Sieving / Direct Interception – particles following the air stream touch a fibre and stick.

- Inertial Impaction – larger particles deviate from airflow lines and collide with fibres.

- 拡散 – sub-micron particles undergo Brownian motion and eventually contact a fibre.

- Electrostatic Attraction – oppositely charged particles are drawn to charged fibres.

The result is outstanding removal efficiency across a broad particle-size spectrum, especially at 0.3 µm—the hardest size to capture.

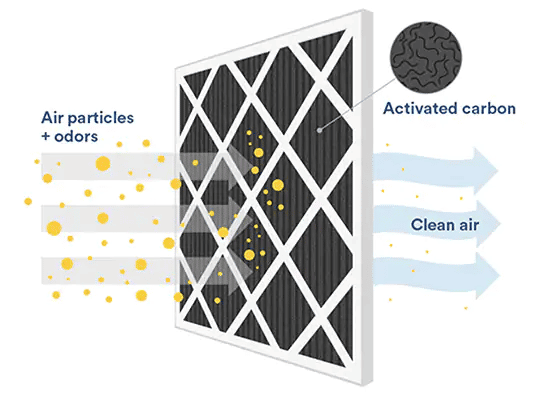

What Is Activated-Carbon Filtration and How Does It Work?

Activated carbon leverages its extraordinary internal surface area—500 – 1,500 m² per gram—to adsorb gaseous contaminants. Typical media formats include granular (GAC), powdered (PAC), extruded (EAC), and acid-washed high-purity carbons.

Removal mechanisms include:

- Physical Adsorption – Van der Waals forces bind gas molecules to the carbon surface.

- Chemisorption – certain gases react chemically with functional groups on the carbon.

- Catalytic Decomposition – impregnated catalysts promote breakdown of specific pollutants.

Different formulations are optimised for Volatile Organic Compounds (VOCs), aldehydes, sulphur compounds, ammonia, ozone, and odours.

HEPA vs Activated Carbon—A Side-by-Side Comparison

| Attribute | HEPAフィルター | Activated-Carbon Filtration |

|---|---|---|

| Primary Target | Solid particulates (dust, pollen, pet dander, mould spores, bacteria, some viruses) | Gaseous pollutants (VOCs, formaldehyde, benzene, ozone, H₂S, NOx) and odours |

| Separation Mechanism | Interception, impaction, diffusion, electrostatic forces | Physical & chemical adsorption, catalysis |

| Efficiency Metric | ≥ 99.97 % @ 0.3 µm | Species-specific; depends on carbon grade, residence time, temperature & humidity |

| Service Life | 6 – 12 months (load-dependent) | 3 – 6 months (saturates irreversibly) |

| Strengths | Unrivalled particle removal; globally standardised ratings | Effective gas & odour control; multiple sorbent chemistries |

| 制限事項 | Ineffective on gases and smells | Limited particulate capture; performance declines in high humidity; no unified rating standard |

| Typical Applications | Dust-laden or allergen-sensitive areas (warehouses, cleanrooms) | Newly renovated spaces, kitchens, laboratories, print rooms |

Why One Technology Alone Is No Longer Enough

Modern indoor environments face a complex pollutant mix: fine particles plus VOCs emitted by building materials, furnishings, electronics, and cleaning agents. A single-mode filter cannot deliver truly comprehensive protection.

Example: In a freshly renovated office

- ヘパ efficiently removes drywall dust and suspended solids—but not formaldehyde or benzene.

- Activated carbon adsorbs those gases—but has minimal effect on PM₂.₅.

Consequently, best-in-class systems integrate both technologies (often alongside photocatalysis, UV-C, or ionisation) to meet contemporary IAQ standards.

Industry-Specific Selection Guidelines

ヘルスケア

- Requirement: control bio-aerosols and disinfectant fumes.

- Solution: medical-grade HEPA (H13/H14) plus specialised carbon beds for anaesthetic gases.

- Outcome: case studies show 99.9 % bacterial reduction and lower staff exposure to nitrous oxide.

Manufacturing & Industrial

- Requirement: capture metal dust, oil mist, welding fume, solvent vapours.

- Solution: industrial HEPA modules combined with impregnated carbon customised for target solvents.

Hospitality & Retail

- Requirement: handle high footfall particulates and diverse odours.

- Solution: high-flow HEPA cores with large-surface carbon honeycombs; optional photocatalytic layer for odour degradation.

Performance & ROI Evaluation Framework

Technical KPIs

- CADR(クリーンエア供給率) – higher values mean faster remediation.

- ろ過効率 – HEPA rating at MPPS must be explicit (e.g., 99.97 %).

- カバーエリア – align purifier airflow with room volume.

- Sound Level – verify dB(A) at typical operating speed.

- エネルギー消費 – assess lifetime power costs.

Financial Returns

- Employee Health & Productivity: improved IAQ cuts sick leave and increases cognitive function.

- Equipment Reliability: clean air reduces failure rates of sensitive electronics.

- HVAC Efficiency: effective pre-filtration lowers coil fouling, saving energy.

The Future of Filtration & HisoAir’s Innovation Edge

Emerging trends point toward multi-technology, energy-optimised, and sector-specific solutions. Drivers include the rise of composite pollutants, stricter energy codes, and bespoke requirements.

HisoAir’s Breakthroughs

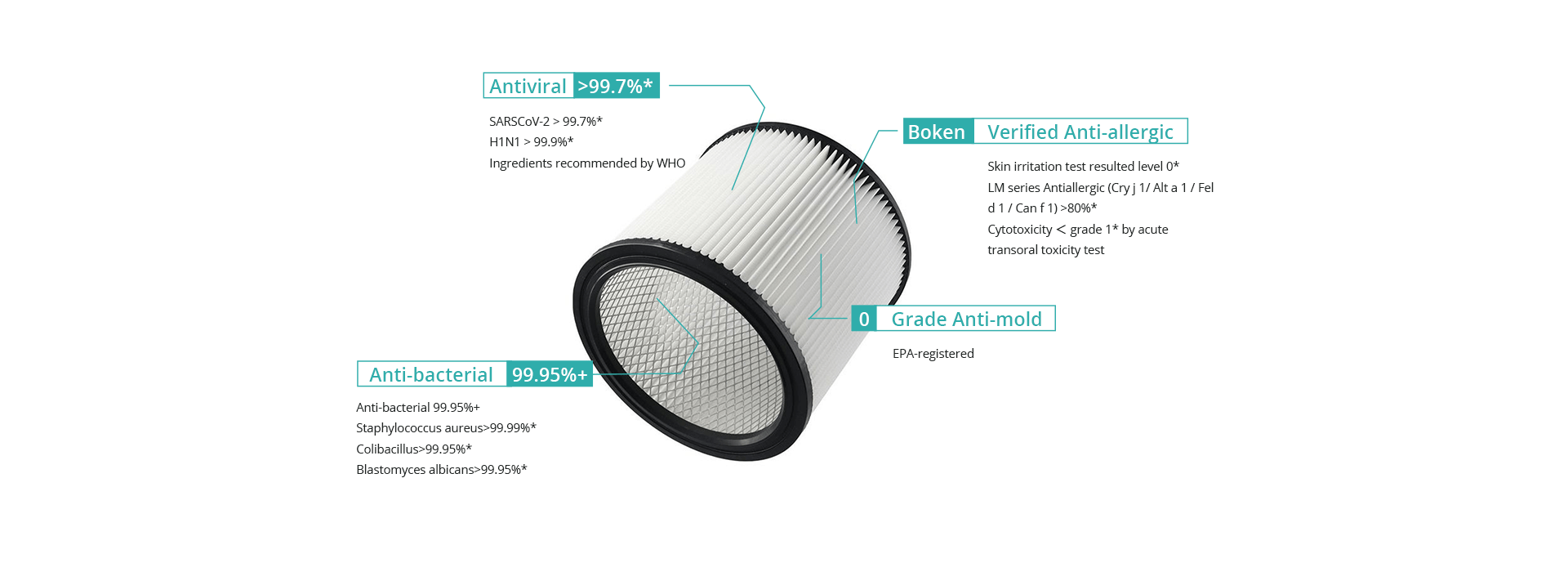

- Low-Resistance HEPA: re-engineered fibre geometry reduces pressure drop while maintaining 99.97 % efficiency, extending filter life.

- Target-Specific Carbon Formulations: proprietary blends maximise adsorption of designated gases for each industry.

- CD (Coated Deodorising) Composite Filters: honeycomb substrates impregnated with multiple sorbents deliver high gas removal at minimal airflow penalty.

Vertically Integrated Manufacturing

HisoAir controls the full value chain—from raw-material processing to final assembly—across several advanced Asian facilities. This ensures:

- Consistent quality, rapid R\&D iterations, and cost advantages.

- Agile customisation to meet evolving norms and client specifications.

Why Global Leaders Choose HisoAir

Superior Product Metrics

- Higher CADR per watt than peer products.

- Longer filter lifetime reduces total cost of ownership.

- Lower acoustics thanks to optimised aerodynamics.

End-to-End Support

- On-site IAQ assessments and solution design.

- Custom product development for unique challenges.

- Worldwide technical service network.

Partnership Roadmap

- Needs Analysis: our specialists map your pollutant profile and operational targets.

- Solution Engineering: we propose a tailored HEPA-plus-carbon configuration.

- Prototype & Validation: sample units undergo on-site performance testing.

Whether you require off-the-shelf best-in-class purifiers or engineered filters for OEM integration, HisoAir delivers clean air that safeguards health and drives business value.

Conclusions & Action Points

- Conduct a comprehensive pollutant audit—identify particulate vs gaseous loads.

- Specify a complementary HEPA + activated-carbon system to cover both vectors.

- Model life-cycle costs—include media replacement, energy, and downtime.

- Prioritise customisation capabilities—every facility is unique; bespoke solutions optimise ROI.

Indoor-air quality is a strategic investment. By harnessing the synergy of HEPA and activated-carbon technologies—and by partnering with an innovation leader like HisoAir—enterprises can create healthier, more productive workplaces and secure a competitive edge.