Have you ever paused to consider where your trusty Vicks humidifier began its journey before landing in your home? It's a question that might seem simple, but as someone who's navigated the intricate world of indoor air quality manufacturing for over two decades, I can tell you the answer reveals a fascinating story about global economics, supply chain strategy, and the very quality of the air we breathe.

Understanding where Vicks humidifiers are manufactured isn't just about pinning a location on a map; it's about decoding the complex web of supply chain resilience, cost structures, and product quality considerations that ripple through to both consumers and businesses like my own.

As the founder of HisoAir, a company deeply rooted in designing and manufacturing high-performance air purifiers, humidifiers, and other IAQ solutions, I've had a unique vantage point. Operating our own factories across China, Vietnam, and Thailand, we haven't just observed these shifts – we've lived them. Our experience developing cutting-edge solutions, like our proprietary Decibel Cancellation™ technology for clients including Fortune 500 companies, gives me a practical, ground-level perspective on the manufacturing decisions shaping this industry.

How Has China Become the Manufacturing Powerhouse for Vicks Humidifiers?

When you look at the global map of humidifier production, one region undeniably dominates the landscape for brands like Vicks: China remains the linchpin, the primary production engine, with deeply entrenched contract manufacturers in the Pearl River Delta and Zhejiang provinces forming the bedrock of their manufacturing ecosystem.

The Pearl River Delta, encompassing cities like Guangzhou, Shenzhen, and Dongguan, is truly the heartland for much of Vicks' humidifier output. Setting up our own HisoAir operations here gave me a profound appreciation for its unique strengths:

- Generational Tooling Wisdom: These manufacturers possess an almost intuitive understanding of plastic injection molding, precision assembly, and the specific quality nuances critical for humidifiers.

- Hyper-Specialized Component Clusters: Imagine industrial parks where neighboring factories specialize in nothing but humidifier motors, atomizers, or PCBs. This density creates incredible supply chain velocity and cost efficiency.

- A Deep Well of Skilled Labor: You find workers who have assembled humidifiers for years, bringing a level of dexterity and efficiency that's hard to replicate quickly elsewhere.

This isn't just about wages. The sheer density of specialized component suppliers in China creates powerful economies of scale. When HisoAir sources motors in China, the intense local competition drives prices down in a way that's simply unmatched elsewhere.

| Manufacturing Factor | China (Baseline) | Southeast Asia (Typical) | North America (Estimate) |

|---|---|---|---|

| Labor Costs (Relative) | 100% | 120-140% | 300-400% |

| 部品調達 | Mature local ecosystem | Partial reliance on imports | Heavily import-dependent |

| Tooling Investment | Lower due to scale/experience | 中程度 | より高い |

| Estimated Overall Cost Index | 100% | 112-118% | 180-220% |

What Challenges Are Pushing Vicks to Explore Southeast Asian Manufacturing?

Despite China's formidable manufacturing advantages, the ground is shifting. Vicks, like many global brands, has been actively scouting and initiating production alternatives in Vietnam, Thailand, and the Philippines. This strategic exploration isn't a whim; it's a calculated response driven primarily by the sting of tariffs and the urgent need for greater supply chain resilience in our increasingly unpredictable world.

The U.S. Section 301 tariffs threw a significant wrench into the well-oiled machine of China-centric manufacturing for the American market. These tariffs, adding anywhere from 7.5% to a hefty 25% onto the cost of goods, became an unavoidable line item that forced brands like Vicks to urgently reassess their manufacturing geography.

In my own conversations with North American clients sourcing IAQ products, the impact was immediate and profound:

- Margin Squeeze: Brands faced the tough choice: absorb the tariff hit (crushing profitability) or pass it onto consumers (risking precious market share).

- Pricing Chaos: Established retail price points, often set months in advance, became unsustainable overnight as landed costs surged.

- Competitive Shuffle: Brands nimble enough to diversify production gained an immediate cost edge over competitors still heavily reliant on China.

Vicks hasn't jumped ship entirely; they've been strategically dipping their toes in the water, running trial production lines in several Southeast Asian nations. Each location presents a unique mix of potential and pitfalls:

| 国名 | Potential Advantages | Observed Challenges | Estimated Landed Cost Premium vs. China |

|---|---|---|---|

| ベトナム | • Strong electronics base • Favorable US trade status |

• Tight skilled labor market • Infrastructure growing pains |

+12-15% |

| タイ | • Advanced manufacturing skills • Relatively stable environment |

• Higher labor costs than Vietnam • Smaller overall labor pool |

+15-18% |

| Philippines | • Widespread English proficiency • Strong customer service culture |

• Less mature component ecosystem • Inter-island logistics hurdles |

+14-16% |

My hands-on experience running factories in both China and Southeast Asia has taught me a crucial lesson: the initial cost projections for diversification often underestimate the real-world premium. While basic manufacturing costs might suggest a 10-12% increase, the fully landed cost difference frequently balloons to 12-18% higher than China once you factor in the less obvious expenses.

Why Do Commodity Humidifier Models Create Margin Pressure for Manufacturers?

In the fiercely competitive landscape of home appliances, basic ultrasonic and evaporative humidifiers have largely transitioned into "red ocean" territory – commodity products where intense price pressure squeezes factory margins wafer-thin, significantly limiting Vicks' flexibility to switch suppliers rapidly without substantial volume commitments or clear feature upgrades.

As a manufacturer producing air quality devices for various global brands, I've had a front-row seat to this commoditization wave. What were once considered somewhat specialized appliances have become mass-market staples, and that shift has fundamentally reshaped the manufacturing dynamics.

For Original Design Manufacturers (ODMs) – the factories that often design そして build products for brands – investing in new tooling for commodity humidifiers is a high-stakes decision. Based on my experience managing factory capital expenditures:

| Investment Category | Typical Cost Range (USD) | Expected ROI Horizon | Minimum Volume Threshold (Units/Year) |

|---|---|---|---|

| Basic Plastic Mold Tooling | $50,000 - $100,000 | 12-18 months | 50,000+ |

| Tooling for Advanced Features | $100,000 - $250,000 | 18-24 months | 30,000+ |

| Complete New Product Line Tooling | $300,000 - $500,000+ | 24-36 months | 100,000+ |

These aren't trivial sums. This reality creates significant inertia against switching manufacturers. When HisoAir evaluates developing a new humidifier platform for a client, we absolutely require one of two things:

- Ironclad Volume Guarantees: Contractual commitments to minimum order quantities (MOQs) that ensure we can amortize the tooling investment over a reasonable period.

- Premium Product Positioning: Specifications and features that allow for healthier margins, justifying the upfront financial risk.

How Does Seasonal Demand Amplify Production Challenges Outside China?

In the world of humidifier manufacturing, there's a powerful force that dictates production schedules and stresses supply chains unlike almost any other factor: the pronounced seasonality of demand. With U.S. sales heavily concentrated between November and February, China's unparalleled manufacturing flexibility becomes a critical competitive advantage – one that newer facilities in ASEAN often struggle to replicate due to stricter overtime rules and shallower labor pools.

The sales pattern for humidifiers in major markets like North America is predictable but extreme:

- Peak Season Dominance: A staggering 60-70% of the entire year's sales often occur within the tight four-month window from November to February.

- Compressed Ramp-Up: Retailers need inventory before the peak hits, meaning factories face intense pressure to produce and ship massive volumes primarily between late August and October.

- Forecast Volatility: An early cold snap or a mild winter can swing actual demand by ±20% or more compared to forecasts, demanding rapid adjustments from manufacturers.

Chinese manufacturers, particularly the established players Vicks relies on, have honed their ability to handle these surges with remarkable dexterity:

| Flexibility Factor | Typical Chinese Practice | Common Southeast Asian Constraint | Impact on Surge Capacity |

|---|---|---|---|

| Weekend Production | Routinely utilized | Often limited by regulations/culture | Adds ~40% weekly output |

| Overnight Shifts | Common during peak season | Restricted or heavily regulated | Adds ~30% daily output |

| Temporary Labor Access | Large, flexible pools readily available | Smaller pools, more hiring friction | Can boost surge capacity 50%+ |

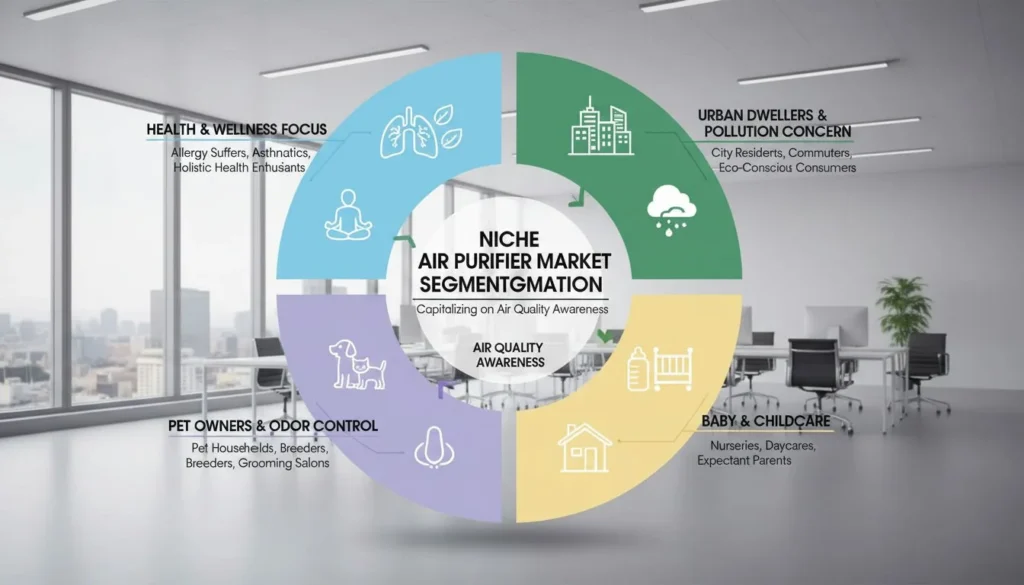

In the wake of a global health crisis and heightened consumer awareness, the humidifier market is undergoing a significant transformation. Savvy post-COVID consumers are no longer satisfied with basic mist; they're actively seeking verifiable pathogen reduction, solutions for mineral-free air, and the convenience of app-based controls. This shift makes a decisive pivot towards premium, health-focused innovation not just an opportunity, but the logical escape route for Vicks to command higher price points (potentially 1.5-2× premium) and break free from the margin-crushing pressures of the commodity market.

The pandemic acted as a catalyst, fundamentally reshaping how people perceive and purchase indoor air quality products:

- Health as the Priority: Consumers now explicitly link indoor air quality, including humidity levels, to respiratory health, sleep quality, and overall well-being.

- Demand for Proof: Vague marketing claims are no longer enough. Buyers want tangible evidence – testing data, certifications, clear technological explanations – for health-related benefits.

- Willingness to Invest: A significant and growing consumer segment is prepared to pay a premium for appliances they believe offer genuine health advantages.

Perhaps the most potent area for premium differentiation lies in technologies that actively combat airborne and waterborne pathogens:

| テクノロジー | Mechanism & Effectiveness | Consumer Resonance | Potential Price Premium |

|---|---|---|---|

| UV-C Sterilization | UV light damages microbial DNA in water/mist (High effectiveness) | Very Strong | +30-40% |

| "Boil-and-Cool" / Steam | Heating water kills most pathogens (Excellent effectiveness) | 強い | +70-100% |

| Silver-Ion Infusion | Slow-release ions inhibit microbial growth (Moderate effectiveness) | 中程度 | +15-25% |

| Continuous Pasteurization | Circulating water through heating element (Very High effectiveness) | Very Strong | +80-120% |

How Is Vicks Advancing Its Dual-Sourcing Strategy Beyond China?

While China undoubtedly remains the operational center of gravity for Vicks humidifier production, the company isn't standing still. Vicks is methodically progressing its dual-sourcing strategy, strategically qualifying secondary suppliers for key components like plastics in Malaysia and PCBAs in Mexico. However, the transition is gradual, with full-unit assembly still heavily (>80%) anchored in China, largely due to the significant hurdles of certification resets, complex firmware revalidation, and demanding retailer line review processes.

Vicks appears to be wisely initiating its diversification not by attempting wholesale shifts of entire assembly lines, but by focusing on key components first. This mirrors the approach we've found effective at HisoAir:

- Plastics (Malaysia): Leveraging Malaysia's mature injection molding industry and competitive cost structure for critical plastic housings and parts.

- PCBAs (Mexico): Tapping into Mexico's burgeoning electronics manufacturing sector, particularly advantageous for supplying the large North American market with reduced shipping times and tariff exposure.

- Motors & Fans (Thailand/Vietnam): Exploring secondary sources for these electromechanical components in other Southeast Asian hubs, albeit likely at a smaller scale initially.

One of the most underestimated roadblocks in shifting manufacturing locations for consumer electronics is the labyrinthine world of product certifications. When HisoAir moved production of an established air purifier model from our China facility to our Vietnam plant, the recertification process alone consumed nearly five months and cost upwards of $30,000 – even though the design, components, and core processes were identical.

What Does the Future Hold for Vicks Humidifier Manufacturing?

As we've journeyed through the intricate world of Vicks humidifier production, a clear picture of the future emerges. It won't be about a single location, but about strategic equilibrium: skillfully balancing China's enduring manufacturing strengths with the resilience gained through thoughtful diversification, all while relentlessly pursuing premium, health-centric innovations capable of transcending the fierce competition of the basic appliance market.

Drawing on my two decades navigating the air quality industry and building HisoAir's multi-national manufacturing footprint, I see several powerful currents shaping the path forward for Vicks and the industry as a whole:

- Regionalization Gains Traction: The pendulum is swinging away from purely globalized, single-source supply chains towards more regionalized manufacturing networks serving local markets.

- Automation Erodes Pure Labor Arbitrage: As robotics and smart automation become more accessible and capable, the simple calculation of chasing the lowest labor cost becomes less dominant.

- Sustainability Becomes Non-Negotiable: Environmental performance is rapidly moving from a 'nice-to-have' to a core business requirement.

For Vicks, the path forward seems clear: continue to balance the efficiency of their established base with the resilience of diversification, fuel growth through meaningful health-focused innovation, and build stronger connections with consumers by clearly communicating the value these advancements bring.