You see "Made in the USA1" on a supplement bottle and feel confident. But what does that label truly mean? The story behind that product is often far more complex.

Major US wellness brands use a mix of sourcing strategies. Many perform final manufacturing and packaging in the US using ingredients sourced globally. Others rely entirely on a network of specialized domestic and international contract manufacturers. The "Made in the USA" label doesn't guarantee US-sourced ingredients.

I've spent my life in the manufacturing world, starting on a factory floor and later building my own mold and CNC business. I learned that the final product you hold is just the tip of the iceberg. The real story is in the supply chain. I once worked on a project for a new line of vitamin bottles. The client was proud their product was "Made in the USA." But the plastic resin for the bottles came from South Korea, the cap from China, and the active ingredients from India and Brazil. This opened my eyes to the complex global dance of modern manufacturing. It’s a dance that every product designer and engineer needs to understand. Let's break down how this intricate system really works.

All products labeled 'Made in the USA' must use 100% American parts and labor.偽

The FTC's 'Made in USA' standard requires that 'all or virtually all' of the product is made in the U.S. However, this often refers to the final assembly and processing, while raw materials can be sourced globally.

The FDA requires supplement manufacturers to follow Good Manufacturing Practices (GMP).真

The FDA's 21 CFR Part 111 establishes GMP regulations that require manufacturers to ensure their products are processed consistently and meet quality standards.

The Manufacturing Maze: Domestic Production vs. Global Sourcing?

Confused by product labels? You see "Made in the USA" but hear about global supply chains. This contradiction can make it hard to understand a product's true origin and quality.

The phrase "Made in the USA" typically means the product underwent its final, "substantial transformation" in an American facility. This often refers to blending, encapsulating, and bottling. The raw ingredients themselves, however, are frequently sourced from a global network of suppliers to get the best quality or price.

In my experience designing molds, this distinction is critical. A client might specify a certain type of plastic for a container. But if they switch from a German supplier to a cheaper one in Vietnam to cut costs, the material properties can change. Even a tiny difference in the plastic's melt flow or shrinkage rate can affect how it performs in the mold I designed. It could lead to defects, wasted material, and production delays. As a designer like Jacky, you have to ask these questions. Where is the material coming from? Has it been tested? Understanding the full supply chain is not just for logistics managers; it's essential for good design and manufacturing.

Domestic vs. Global Sourcing: A Comparison

| アスペクト | Domestic Sourcing (USA) | Global Sourcing (International) |

|---|---|---|

| コスト | Generally higher labor and raw material costs. | Often lower costs due to labor and material availability. |

| 品質管理 | Easier to monitor, with direct oversight of factories. | More complex; requires trusted partners and rigorous testing. |

| Lead Time | Shorter and more reliable shipping times. | Longer lead times, potential for customs and shipping delays. |

| Regulations | Must adhere to strict US standards (FDA, FTC). | Varies by country; requires verification of compliance. |

Global sourcing always results in a lower-quality product.偽

Many countries specialize in producing high-quality raw materials that may not be available in the US. Quality depends on the supplier and the brand's own quality control systems, not just the country of origin.

Supply chain disruptions, like port delays, can significantly impact brands that rely on global sourcing.真

Brands that source ingredients or components from overseas are more vulnerable to global shipping issues, which can lead to stock shortages and production halts.

"Clean" and "Natural": The Quest for High-Quality Ingredients?

Brands fill their labels with words like "clean," "pure," and "natural." But with ingredients coming from all over the world, how do they actually guarantee quality and safety?

Reputable brands don't just trust their suppliers. They verify. The foundation for this is the FDA's Current Good Manufacturing Practices (cGMP). This is a set of rules that dictates everything from facility cleanliness to record keeping, ensuring a safe and consistent product. The best brands then add their own layers of testing on top of that.

Think of cGMP as the minimum requirement, the price of entry. In the molding business, we have similar standards, like ISO 9001, that show a factory has a solid quality management system. When I was choosing manufacturing partners for my trading company, a cGMP or ISO certification was the first thing I looked for. It told me they had disciplined processes. For wellness brands, this means testing raw ingredients when they arrive for identity, purity, and contaminants. They test the product again during manufacturing and once more after it's finished. This "test-everything" approach is the only way to truly stand behind a "clean" label when your supply chain spans continents. It’s a burden of proof that separates the serious players from the marketers.

Key Pillars of Ingredient Quality

- cGMP Compliance2: This is non-negotiable. It ensures that the manufacturing facility meets the FDA's baseline for safety and quality. It covers personnel, equipment, production processes, and documentation.

- Supplier Qualification3: Serious brands don't just find a supplier online. They audit them. They visit the farms and factories to see the conditions for themselves. They build long-term relationships based on trust and verification.

- Multi-Stage Testing4: Quality isn't checked just once.

- Raw Material Testing: Verify the identity and purity of each ingredient upon arrival.

- In-Process Testing: Ensure the formula is being mixed correctly.

- Finished Product Testing: Confirm the final product meets all label claims and is free of contaminants.

The term 'natural' on a label is strictly regulated by the FDA.偽

The FDA has not developed a formal definition for the term 'natural.' The agency's general policy is that it means nothing artificial or synthetic has been included in, or has been added to, a food that would not normally be expected to be in that food.

Third-party testing provides an unbiased verification of a product's quality and label claims.真

Organizations like NSF, USP, and ConsumerLab.com independently test products to confirm that they contain what the label says, are free from harmful contaminants, and have been manufactured according to cGMPs.

The Transparency Trend: Are Brands Really Pulling Back the Curtain?

You're tired of marketing fluff and want real answers. Where did this come from? How was it made? Smart brands are listening and realizing that transparency is their most powerful tool.

Yes, the most forward-thinking brands are becoming radically transparent. They are moving beyond simple marketing claims and providing verifiable proof of their sourcing and quality. This includes sharing the locations of their suppliers, posting lab results for every batch, and explaining their entire manufacturing process.

This shift is changing how we design everything, including packaging. I remember a client who wanted to add a QR code to their product's cap, which I was designing the mold for. This QR code linked to a webpage showing the farm where the main ingredient was grown, along with the certificate of analysis for that specific batch. It was a brilliant move. It turned the simple plastic cap into a gateway for trust. For a designer like Jacky, this means thinking beyond just the shape and function of a package. You now have to consider how to integrate these new layers of information. Space for QR codes, room for multiple certification logos, and even the choice of materials can all communicate a brand's commitment to transparency. It's a new era where the product's story is part of its design.

How Brands Demonstrate Transparency

| 方法 | 説明 | Example for a Product Designer |

|---|---|---|

| Traceability Tech | Using QR codes or blockchain to allow consumers to trace a product's journey from source to shelf. | Designing a label or cap with a dedicated, scannable space for a QR code. |

| Third-Party Certs | Displaying seals from respected organizations like NSF, USDA Organic, or Non-GMO Project. | Allocating sufficient space in the package design to display multiple certification logos clearly. |

| Open Sourcing | Creating detailed content (videos, web pages) that shows the farms, factories, and people in the supply chain. | Designing a package that prompts the user to "See our story" online, connecting the physical product to digital content. |

| Public Lab Results | Publishing the Certificates of Analysis (CofA) for each product batch on their website. | Ensuring the batch number is clearly printed and legible on the product, so customers can look it up. |

All wellness brands are required by law to be transparent about their ingredient suppliers.偽

While brands must list ingredients, there is no law requiring them to disclose the specific source or country of origin for each ingredient. Transparency is a voluntary marketing and trust-building strategy.

A Certificate of Analysis (CofA) is a document that confirms a product meets its predetermined specifications.真

A CofA is a key quality control document. It is issued for each batch of product and provides results from tests performed to ensure its identity, purity, and potency.

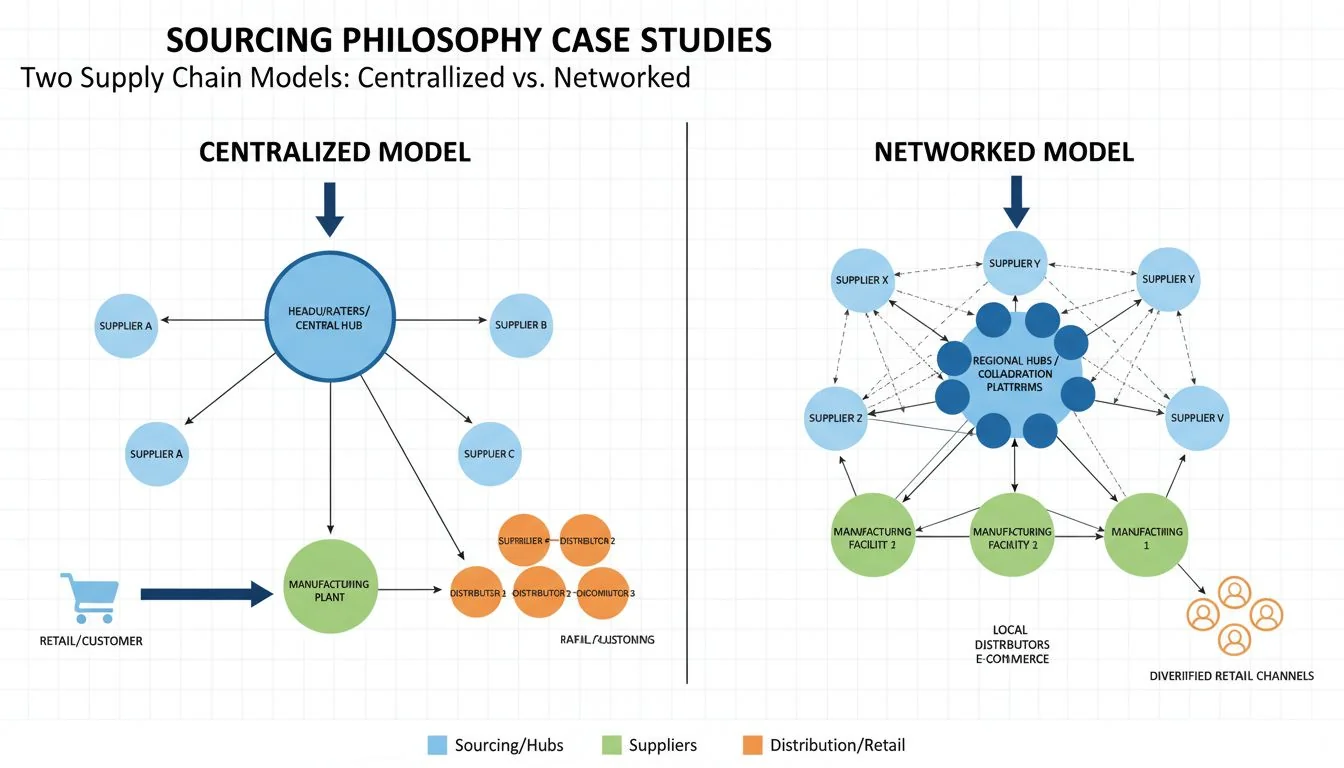

Case Studies in Sourcing: A Tale of Different Philosophies?

You know the concepts, but how do they apply in the real world? Every company makes different choices based on their goals. There is no single "best" way to source and manufacture.

Let's look at two common but different approaches. Some brands choose to control every step by building their own massive, state-of-the-art factory. Others decide to stay lean and partner with a network of specialized contract manufacturers who are experts in specific areas. Each philosophy has powerful advantages and disadvantages.

I've seen this firsthand in the molding industry. Some of my largest clients were huge companies with their own in-house molding departments. They had total control, but their overhead was massive. They also struggled to adapt to new technologies because they had so much invested in their existing equipment. On the other hand, I worked with many smaller, innovative startups. They outsourced their molding to specialists like me. This allowed them to be flexible, access the latest technology without the capital investment, and focus on what they did best: design and marketing. Neither model is inherently better. The right choice depends on the company's scale, priorities, and long-term vision. For a product designer, understanding these business models helps you tailor your designs for either a high-volume, standardized system or a more agile, outsourced one.

Sourcing Model Breakdown

| アスペクト | Brand A: "The Controller" (In-House) | Brand B: "The Networker" (Outsourced) |

|---|---|---|

| Core Strategy | Own and operate their own manufacturing facilities. | Partner with multiple third-party contract manufacturers. |

| 長所 | Total control over quality and process; protection of intellectual property. | Lower capital investment; access to specialized expertise; greater flexibility. |

| 短所 | High overhead and capital costs; less agile to market changes. | Less direct control; reliance on partners' quality systems; potential for IP risk. |

| Best For | Large, established brands with high volume and stable product lines. | Startups and brands with diverse or rapidly changing product lines. |

Using contract manufacturers means a brand has no control over quality.偽

Reputable brands maintain strict quality control over their contract manufacturers through rigorous audits, binding quality agreements, and independent testing of the final product.

Building your own factory is always the most profitable model in the long run.偽

While it can be profitable, the high initial investment and ongoing operational costs can be a significant burden. The profitability depends on maintaining high production volume and efficiency.

Walking down the wellness aisle can be overwhelming. Every bottle makes a bold promise. How do you cut through the noise and choose a product you can actually trust?

The secret is to ignore the flashy marketing on the front and act like an auditor. Turn the bottle over. Look for evidence and proof, not just promises. The most trustworthy brands make it easy for you to find this information.

As someone who makes physical things, I believe that quality is built-in, not just inspected at the end. It starts with the design, the raw materials, and the process. The same is true for supplements. A trustworthy product isn't just about a good formula; it's about a good process. When you're looking at a product, you're really evaluating the quality of the company's entire system. As a designer, understanding what a discerning customer looks for helps you create products that meet and exceed those expectations. It forces you to think about the details that build trust, from clear labeling to quality certifications.

Your Quality Checklist

- GMP Certified: Look for a statement on the label that says the product was made in a "GMP-Certified Facility." This is a fundamental sign of quality.

- Third-Party Testing: Does the label have seals from organizations like NSF, USP, or UL? This means an independent body has verified the product's contents and purity.

- Clear Labeling: Are the ingredients and their amounts listed clearly? Avoid "proprietary blends" that hide the exact dosage of each component.

- Transparency Clues: Does the brand have a website that talks about its sourcing? Do they offer a way to see lab results? This shows a commitment to openness.

- Contact Information: Is there a clear address and phone number for the company? A brand that is easy to contact is more likely to stand behind its product.

A 'proprietary blend' is a way for brands to protect their unique formula from competitors.真

This is the reason brands use them. However, it also prevents consumers from knowing the exact amount of each ingredient they are consuming, which can be a significant drawback.

If a supplement is sold in a major US retail store, it has been pre-approved by the FDA for safety and effectiveness.偽

The FDA does not approve dietary supplements for safety or effectiveness before they are marketed. The responsibility for ensuring safety and accurate labeling falls on the manufacturer.

The Future of Wellness Sourcing: What's Next with Sustainability, Ethics, and Technology?

The manufacturing world never stands still. The conversation around sourcing is evolving beyond just quality and cost. The future is about making things better, not just for the consumer, but for the planet.

The future of sourcing will be defined by three key trends: sustainability, ethical practices, and technology. Consumers are demanding products that are not only effective but also environmentally friendly and socially responsible. Technology like blockchain will provide an unprecedented level of transparency to prove it.

This is an exciting time for manufacturing and design. In my field, we're seeing a huge push for using post-consumer recycled (PCR) plastics. Designing a mold for PCR material is a different challenge than using virgin plastic. It has different flow characteristics and requires a different design approach. But it's a challenge we must meet. Similarly, the rise of Ethical Sourcing5—ensuring fair wages and safe conditions for workers on farms and in factories—adds another layer of complexity and importance to the supply chain. For designers like Jacky, the future means creating products that are not just functional and cost-effective, but also sustainable and ethical. The product's story and its impact on the world are becoming as important as the product itself.

The Next Wave in Sourcing

- Sustainability: This means using recycled and renewable materials for packaging, minimizing the carbon footprint of shipping, and sourcing ingredients that are farmed sustainably. For example, using PCR plastic for bottles and jars.

- Ethical Sourcing: This involves ensuring that everyone in the supply chain, from the farmer to the factory worker, is treated fairly and paid a living wage. Certifications like Fair Trade are becoming more common.

- 技術だ: Blockchain technology offers the potential for a fully transparent and unchangeable record of a product's journey. A consumer could scan a code and see every single step, from the seed being planted to the bottle being sealed.

Using recycled plastic for packaging is just as easy as using new plastic.偽

Recycled (PCR) plastics can have more variability in their properties than virgin plastics, which presents challenges in mold design and processing to ensure consistent quality.

Blockchain can create a permanent and verifiable record of a product's supply chain journey.真

Because blockchain is a decentralized and immutable ledger, it can be used to track a product from its origin to the final consumer, increasing transparency and preventing fraud.

結論

Understanding a product's journey is no longer optional. The best brands prove their quality through transparency, a principle that holds true for every single thing we manufacture and design.

References

-

Explore the complexities behind the 'Made in the USA' label and what it signifies about sourcing. ↩

-

Understand the importance of cGMP compliance in maintaining product integrity and consumer trust. ↩

-

Discover the rigorous processes brands use to ensure their suppliers meet quality standards. ↩

-

Find out how multi-stage testing guarantees the quality and safety of wellness products. ↩

-

Understand how ethical sourcing practices are shaping the future of product manufacturing. ↩